12

OIL RECOMMENDATION AND SPECIFICATION

Recommended Oil

Eagle Compressor Oil # EAQIL 10 (1 Litre)

# EAOIL 40 (4 Litres)

Eagle Compressor Oil is a non-detergent mineral oil formulated with additives to help minimize carbon build-up, increase

ring life and reduce oil consumption. Regular oil changes with Eagle Compressor Oil will increase performance and life

expectancy. Manufactured for use at ambient temperatures of 0°C. to 30°C.

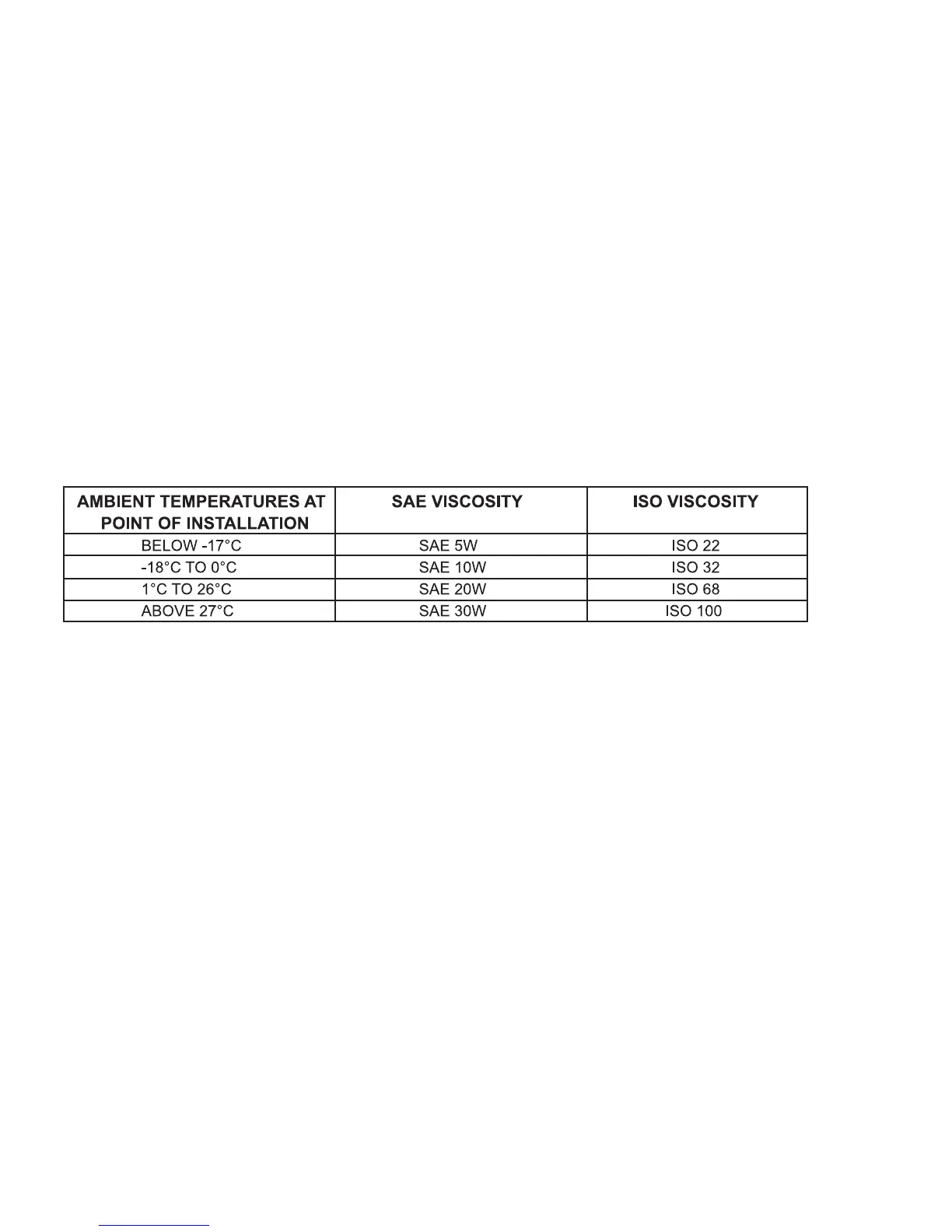

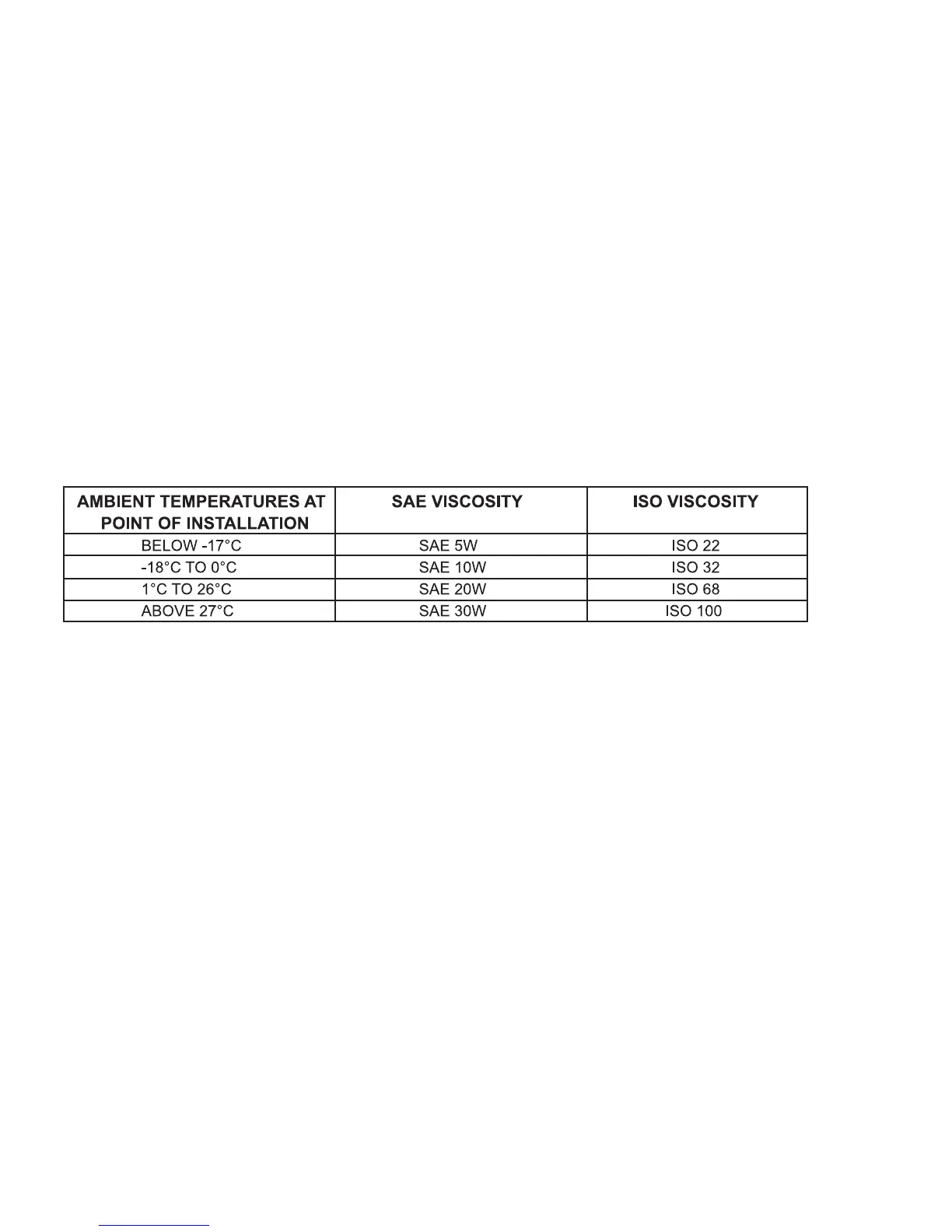

Other Approved Oils

Regular Mineral Oils can also be used in Eagle Compressors.

*Always use a non-detergent oil with the following specification:

• The lubricant selected must have a pour point of at least 10°C lower than the minimum expected ambient

temperature.

• Engine crankcase, “if gasoline engine operated,” fill in accordance with engine manufacturers’ recommendations found

in engine manual.

• Electric motors are usually equipped with sealed-for-life bearings and require no additional lubrication.

• Never use a multi-weight detergent motor oil in your compressor.

INITIAL START-UP OF YOUR COMPRESSOR

SAFE PRACTICES ARE MANDATORY WHEN DEALING WITH COMPRESSED AIR, THEREFORE, THE

FOLLOWING PROCEDURE SHOULD BE FOLLOWED FOR: START-UP OF A NEW INSTALLATION, START-UP

AFTER CHANGES HAVE BEEN MADE TO AN EXISTING INSTALLATION, AND START-UP AFTER SERVICE

REPAIR WORK HAS BEEN PERFORMED.

Checklist

• Make sure no installation debris or tools are on or around the compressor.

• Check oil level (See Adding Oil)

• Check belt tension (See Checking Belt Tension)

• Rotate flywheel to make sure it rotates freely

• Make sure all guards are in place

• Check fuses or thermal overloads for proper size

• Open all manual shut-off valves

• Jog the starter switch to check rotational direction of the compressor. It should rotate as per the directional arrow on

the compressor flywheel.

• The rotation is right when the cooling fins inside the flywheel are blowing air towards the compressor.

Loading...

Loading...