5

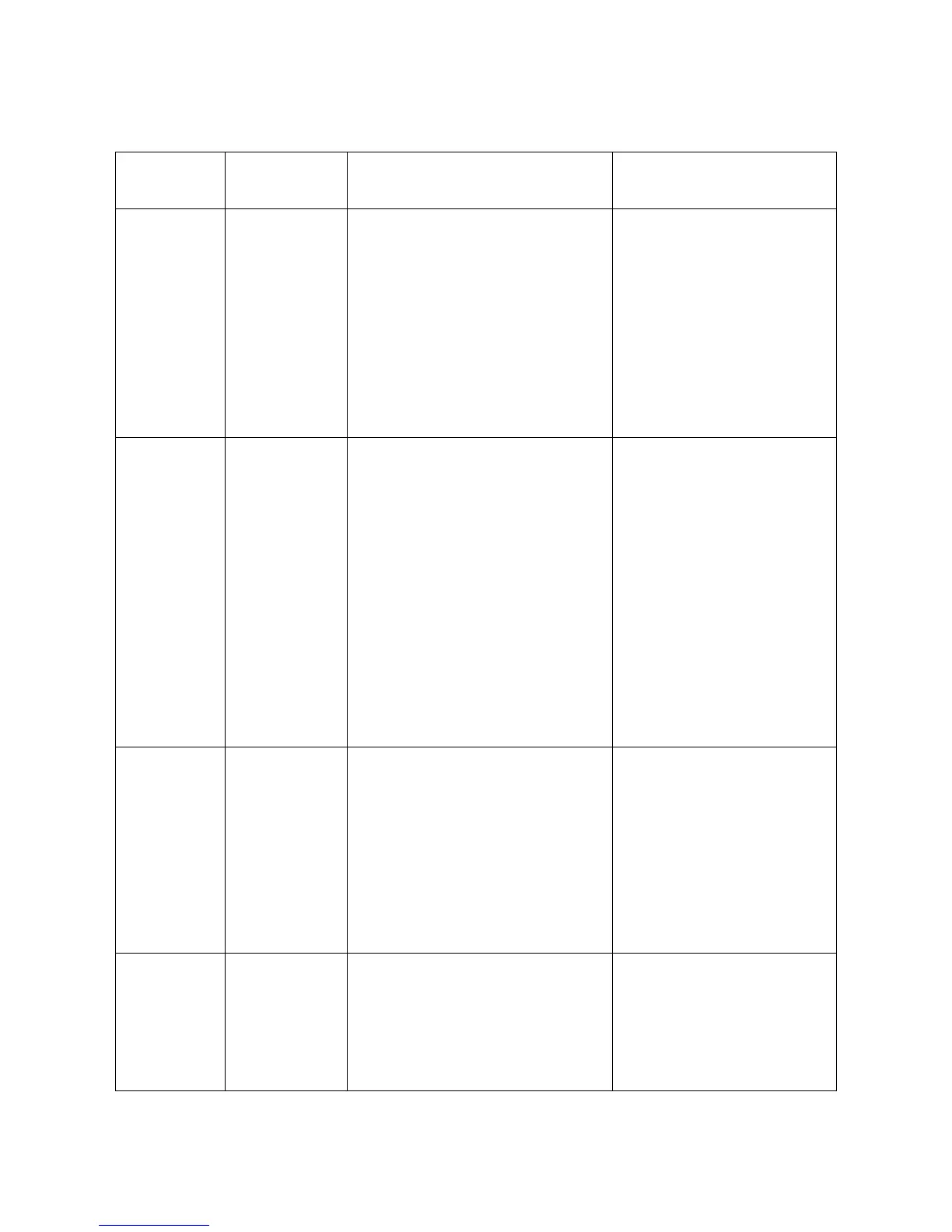

IV. Malfunction catalog

Common Trouble and processing Methods are listed as follow:

Serial NO. Phenomenon Description Maintenance Methods

01

No Function

When Starting.

The LCD isn’t illuminating:

①Fuse melts (in the Power Source Box

or on the main PCB).

②Power supply circuit poorly

connected.

③EMC Board fails.

④main PCB fails.

① Replace Fuse.

② Replace Power Box.

③ Replace EMC Board.

④ Replace main PCB.

02

No function

when starting.

The LCD is illuminating:

①Mechanical switch fails or it’s wire is

opened.

②Up or Down Stroke Photo-electricity

fails.

③Main PCB fails.

④Kneading is on without pressing any

key when starting and no response by

pressing other keys.

①Replace mechanical switch or

it's wire.

②Replace Stroke Photo-

electricity.

③Replace the main PCB.

④Width Inspection Board of

PCB fails, replace it.

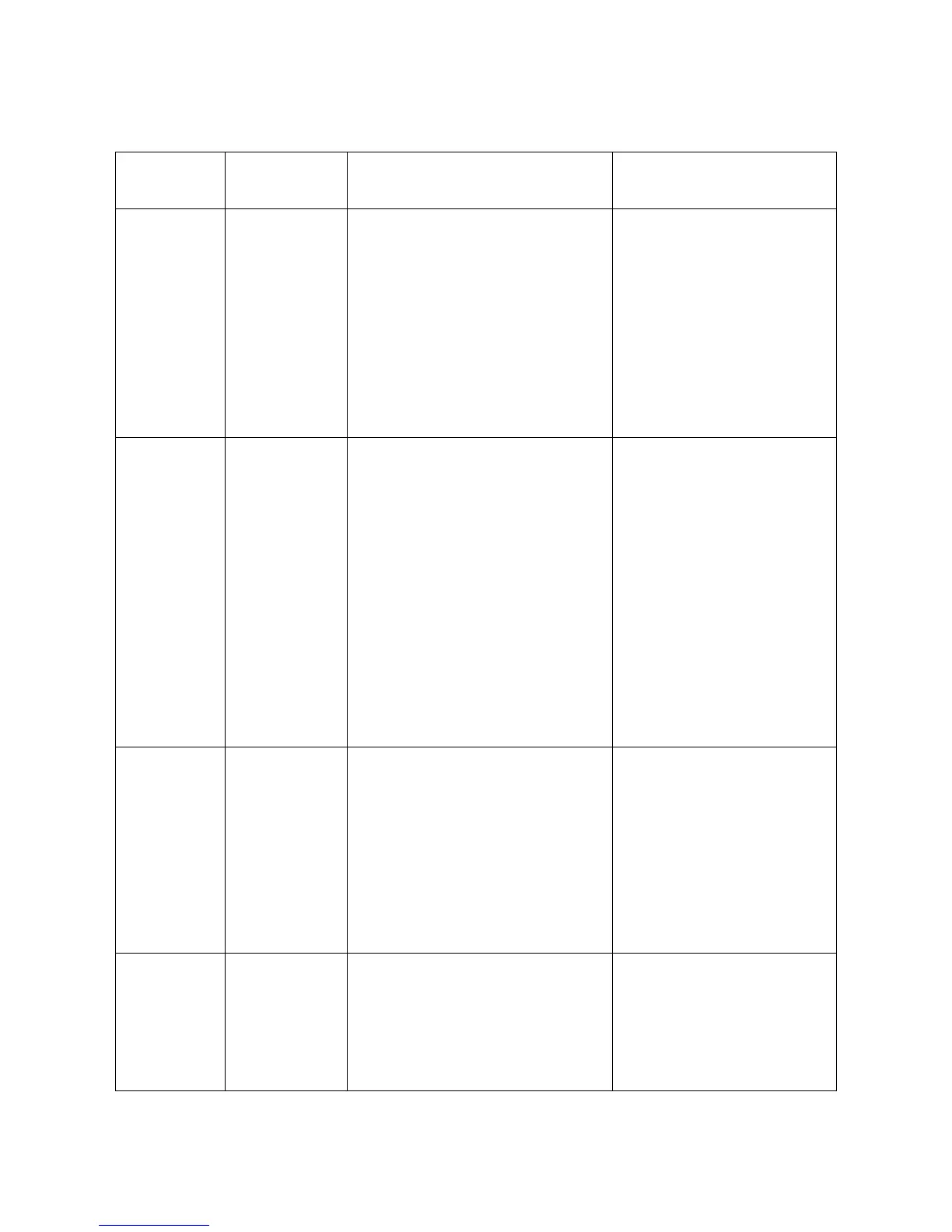

03

No Width

switchover.

①The terminals of Width Inspection on

main PCB and wires are poorly

connected.

②The terminals of Width Inspection on

massage mechanical and wires are

poorly connected.

③ Width Inspection fails.

④ Main PCB fails.

①&②Plug the terminal securely

or replace the wires.

③ Replace Width Inspection.

④ Replace the main PCB.

04

No Partial

Function.

①Height Inspection Terminal or wire

poorly contacts.

②Height Counting Subassembly fails.

①Plug the terminal securely or

replace the wires.

②Replace Height Counting Sub

-assembly.

Loading...

Loading...