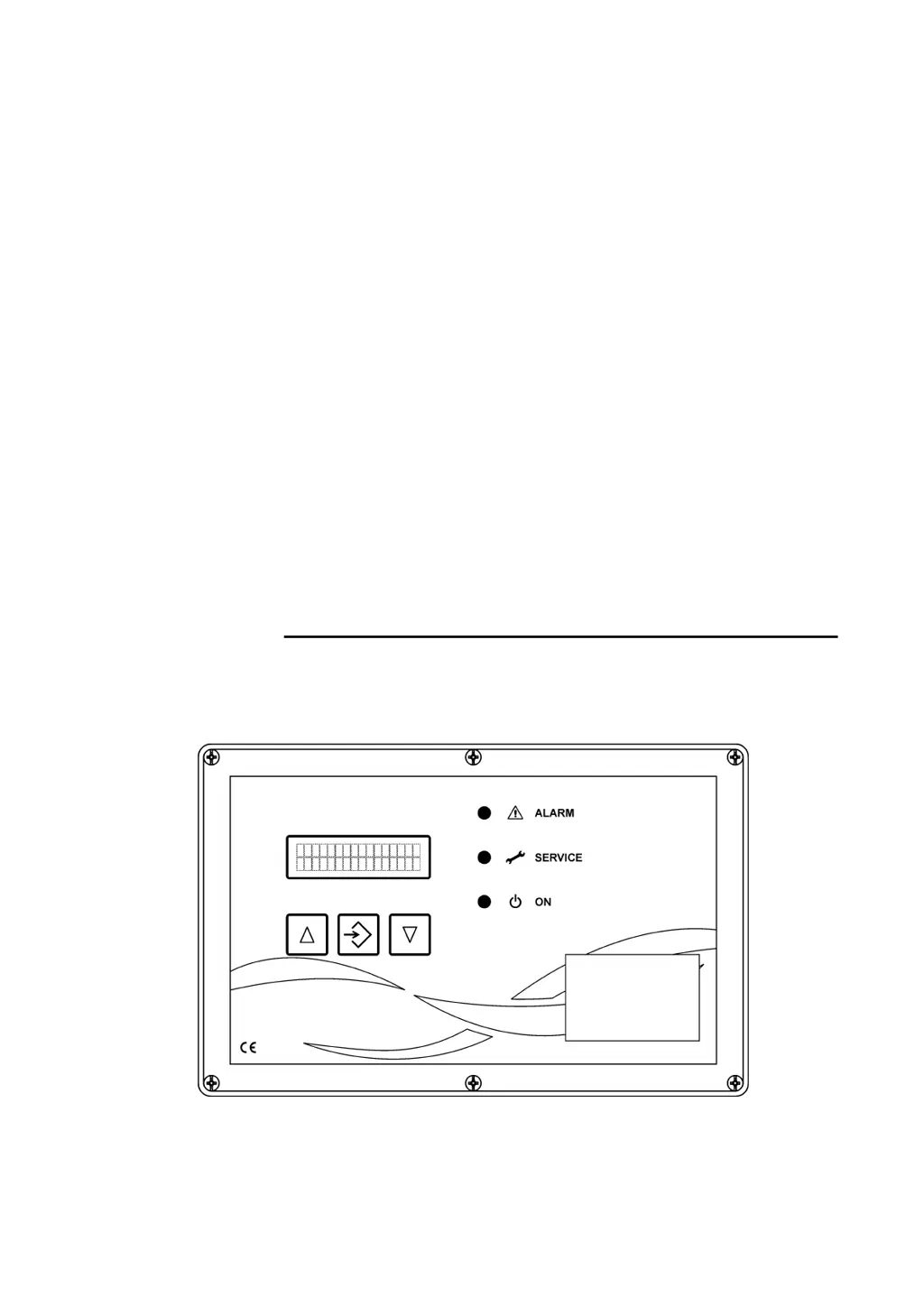

What to do if my EasyLine Control Systems cleaning is ineffective?

- AAndrew SnyderAug 4, 2025

If the cleaning is ineffective, it could be due to several reasons. The interval time might be too long, in which case you should set parameter P02 “Interval” to a lower value. The pressure could be too low; set the pressure to 6 ... 8 bar (min. 5 bar) and consider setting parameter P02 “Interval” to a higher value. A valve might be faulty, so check or replace the valves. Finally, the pulse time might be too short; set parameter P01 “Pulse time” to a higher value.