3EATON Series 1 heavy Duty Hydrostatic Fixed Displacement Motors Repair E-MOPI-TS002-E September 2004

ID Tag

A - Displacement (cu.in./rev.)

0033 = 3.3

0039 = 3.9

0046 = 4.6

0054 = 5.4

0064 = 6.4

B

- Identifies Type of Product

31 = Fixed Displacement Motor with Face Seal

33 = Fixed Displacement Motor with Lip Seal

C - Identifies Specific Unit Configuration

D - Month of Manufacture

E - Year of Manufacture

F - Specific Serial Number of Unit

•Stationary Seal Puller (1/4

in. x 20 UNC capscrew,

3 to 4 in. long)

• Retaining Ring Pliers,

No. 5 or 7

•Breaker Bar or Ratchet

Wrench

• 1-3/8 in. Hex Wrench

•1 in. Hex Wrench

• 9/16 in. Socket

• 5/8 in. Socket

•Torque Wrench

(200 lb-ft capacity)

• 1/4 in. Hex Bit Socket

• 1/4 in. Hex Key

• Loctite® No. 271

• Pliers

• Punch

• Magnetic Base Indicator

• Hammer

• Bearing Press or Driver

•Light Petroleum Jelly

• Cleaning Solvent

• Micrometer or Vernier

Calipers

• Small Screwdriver

(1/8 in. blade)

• Clean Lint Free Rags

Special Tools needed

(shown on pages 26 and 27).

• Bearing Cone Driver

• Rotating Seal Puller

• Limit Stop for Bearing

Cone Installation

• Headless 5/16 in. Cap

Screws, 5 to 6 in. Long (2)

• Low Clearance Bearing

Puller

Tools Required

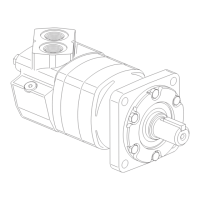

This manual will provide you with service information and procedures for disassembly and reassembly of Eaton

®

Series 1 Heavy Duty Hydrostatic Fixed

Displacement Motors – Models 33, 39, 46, 54, and 64. Procedures outlined in this manual will allow you to better service your motors and obtain the best

results possible. To ensure accuracy of repair and prevent part loss or damage, certain components or subassemblies are disassembled, inspected, and

reassembled when removed from the motor.

Note: All requests or inquiries must be accompanied by the complete model and serial number.

Introduction

Important: Cleanliness is extremely important when repairing a hydrostatic pump or motor. Before disconnecting the lines, clean foreign material

from exterior of unit. Work in a clean area. Clean all metal parts in clean solvent. Blow parts dry with air. Don’t wipe parts with cloth or paper towel,

because lint or other matter could cause damage. Check all mating surfaces. Replace any parts that have scratches or burrs that could cause leakage.

Don’t use coarse grit paper, files or grinders on parts.

Note: All torque specifications are for lubricated threads. Bolts for gasketed surfaces should be checked for proper torque.

A good service policy is to replace all old seals with new seals whenever unit is disassembled. Lubricate seals (except metal sealing surfaces of shaft

seal assembly) with petroleum jelly. Use only clean, recommended oil when assembling unit. See Hydrostatic Fluid Recommendations on page 28-29 or

publication 03-401 and 03-405.

Refer to specific motor assembly

part listings for your Eaton motor

when ordering replacement parts.

Parts Lists are available from Eaton.

Sample tag shows motor

identification.

When ordering replacement parts,

you must include the

following information:

Loading...

Loading...