MAINTENANCE AND SERVICING

Damaged equipment may cause serious personal injury. Do not use damaged

equipment. If abnormal noise or vibration occurs, have the problem corrected before

further using.

1. Before each use, inspect the general condition of the tool. Check for loose screws,

misalignment or binding of moving parts, cracked or broken parts, or any other

condition that may affect its safe operation.

2. After using, clean external surfaces of the tool with clean, moist, smear the rust

preventing oil on the metal surface of the tool and the dies to avoid rusty. Store the

tool in the dry environment.

3. Service to the tool should only be done by a qualified Service Technician.

4. After a long time, the sealing kits will be damaged, if there is leakage please contact

the manufacturer and/or the distributor to have the sealing kits changed.

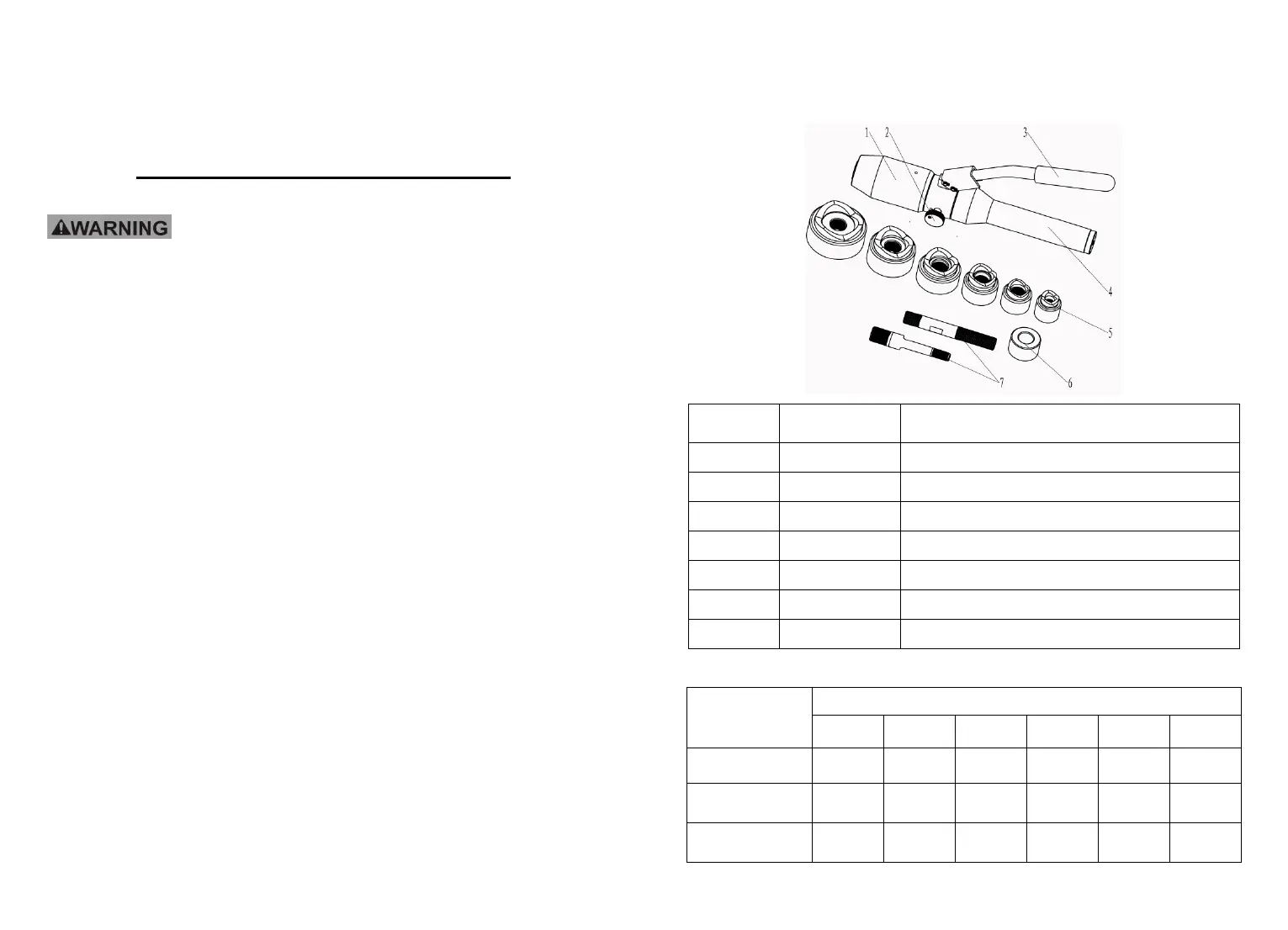

1

Description of the components.

Code Name Function

1 Ram Output high pressure to active the piston

2 Turn screw To release the pressure

3 Active handle For operating

4 Fixed handle For storing oil and protect rubber bladder

5 Punch &die For punching

6 Spacer To protect the ram and assist tool for punching

7 Draw Stud For connecting cylinder with punch & die

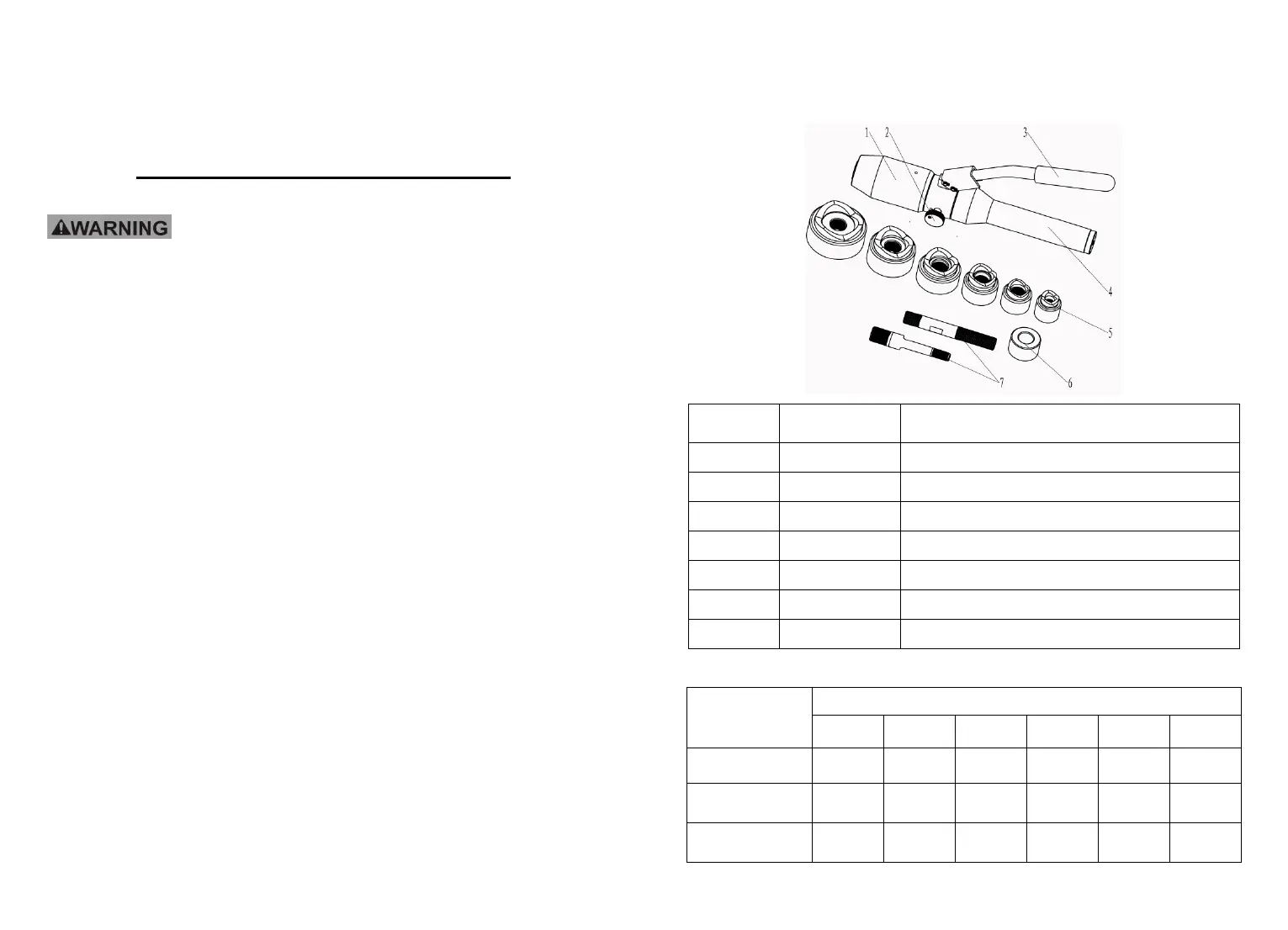

Capacity and Draw Stud Selection Guide

Draw Studs and

Accessories

Standard Round Knockout Punches (Type D)

.89” 1.11” 1.36” 1.71” 1.96” 2.43”

▲

+Spacer

▲ ▲ ▲

3/4”Draw Stud

▲ ▲

Loading...

Loading...