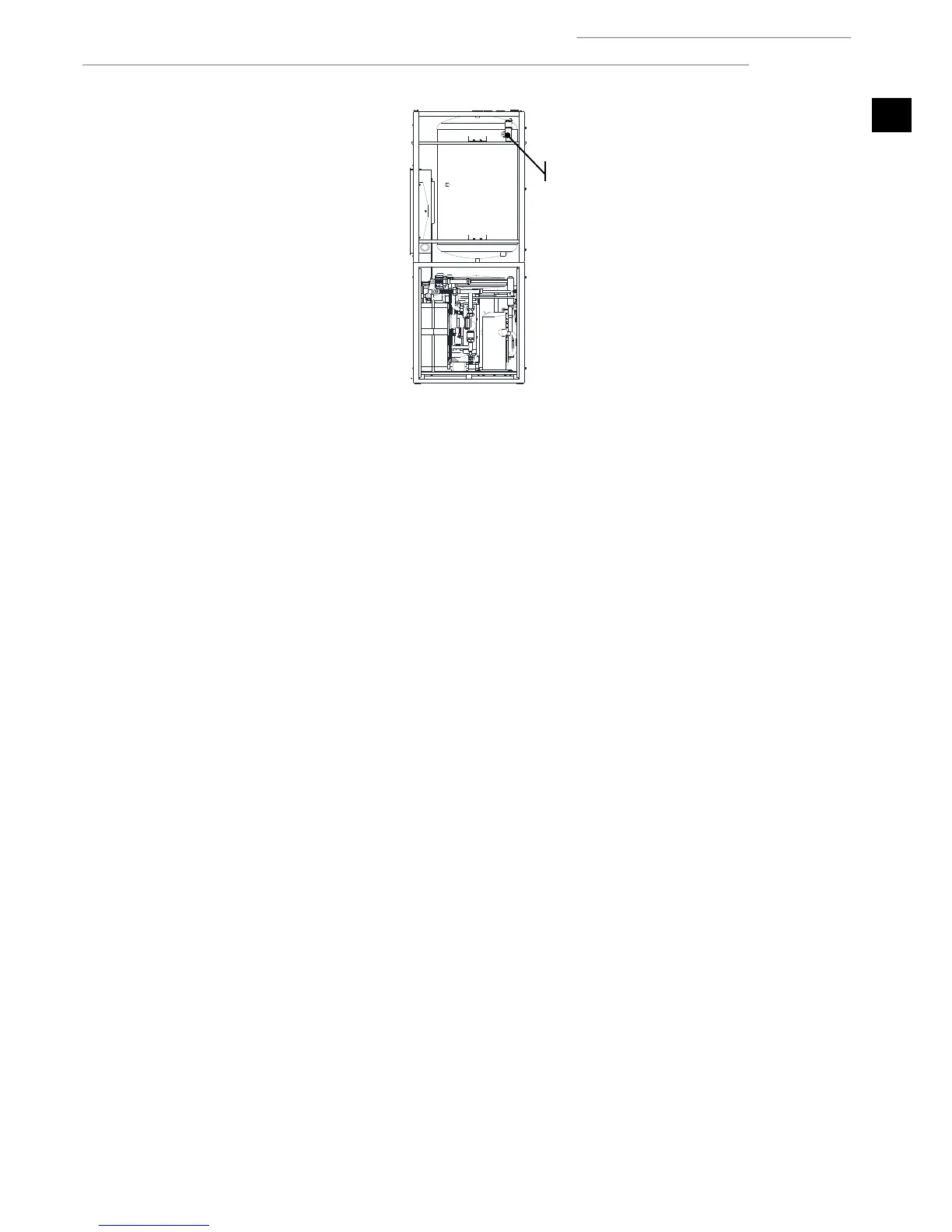

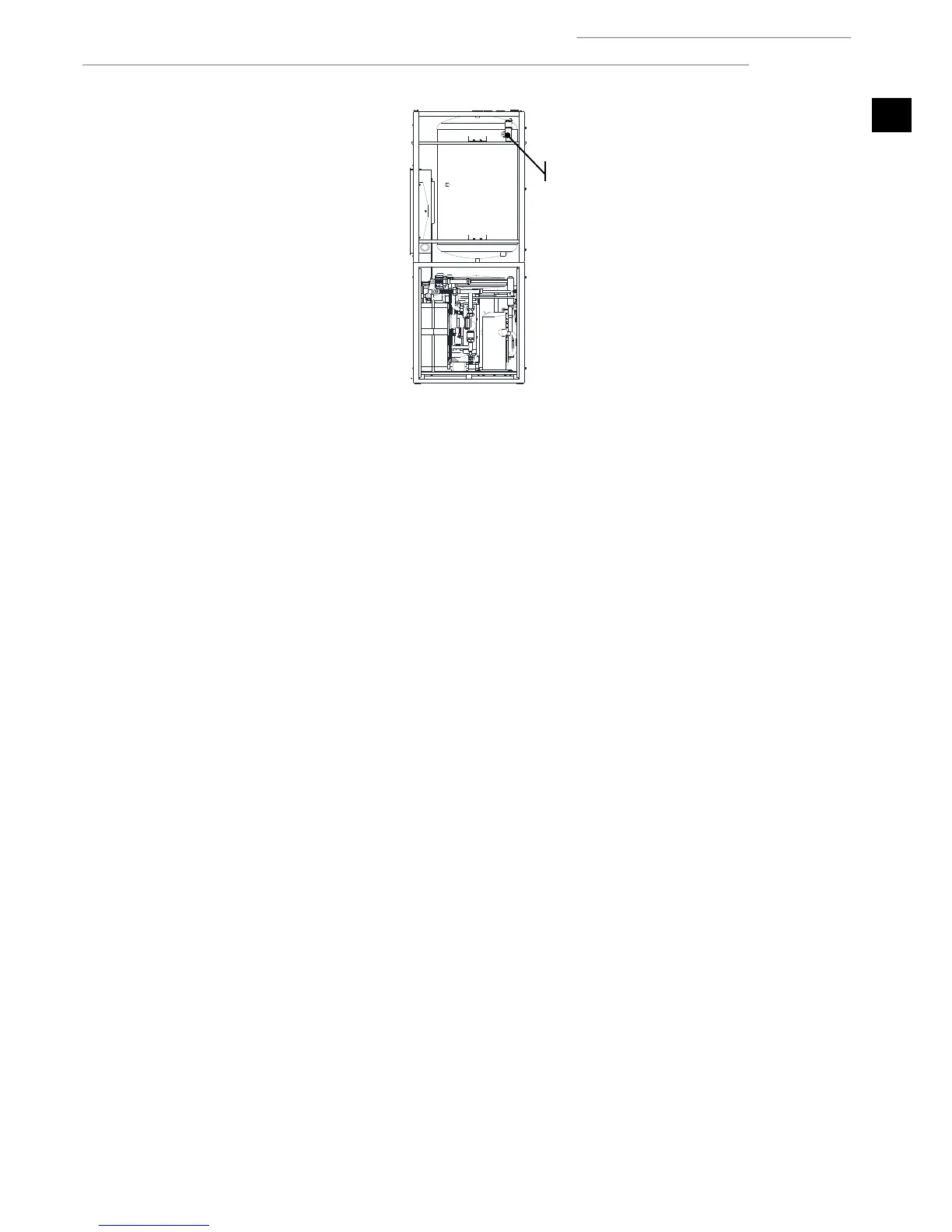

Figure 1.14.Bleeding the DHW production circuit in ecoGEO Compact models.

4.2. Filling the brine circuit

The brine system temperature can fall below 0°C, so a mixture of water/antifreeze must be used. It is recommended to use propylene

glycol as an antifreeze additive or ethylene glycol with a corrosion inhibitor. Please check local regulations before using any type of

antifreeze mixture.

When preparing the mixture, be careful to calculate the volume of antifreeze necessary to reach the desired degree of antifreeze

protection. It is recommended to use a mixture with a freezing point at least 10ºC below the nominal minimum temperature.

Brine circuit filling should be done with the filling unit installed in the return pipe and an external circulation pump, taking the

following steps.

1. Prepare the appropriate proportions of antifreeze mixture in external tank A.

2. Connect the external recirculation pump outlet to valve D.

3. Connect a transparent hose from valve E to antifreeze mixture tank A.

4. Close valve C and open filling valves D and E.

5. Start the external recirculation pump and keep it running until the return is completely free of air and the antifreeze mixture

is mixed perfectly.

6. Open valve C and keep the external pump connected to remove the air between valves D and E.

7. Close valve E and pressurise the circuit to target pressure. Make sure that the pressure does not exceed 3 bar (pressure gauge)

under any circumstance.

8. Close valve D.

After completing the brine circuit filling process, it is recommended to check the concentration of antifreeze mixture again using a

refractometer.

Loading...

Loading...