BASIC MAINTENANCE PROCEDURESBASIC MAINTENANCE PROCEDURES

Follow the procedure below to make adjustments to the drive chain slack. Be sure that you are parked on a level

surface and the engine is turned OFF.OFF.

CHECKING BRAKE PADSCHECKING BRAKE PADS

DRIVE CHAIN ADJUSTMENT DRIVE CHAIN ADJUSTMENT

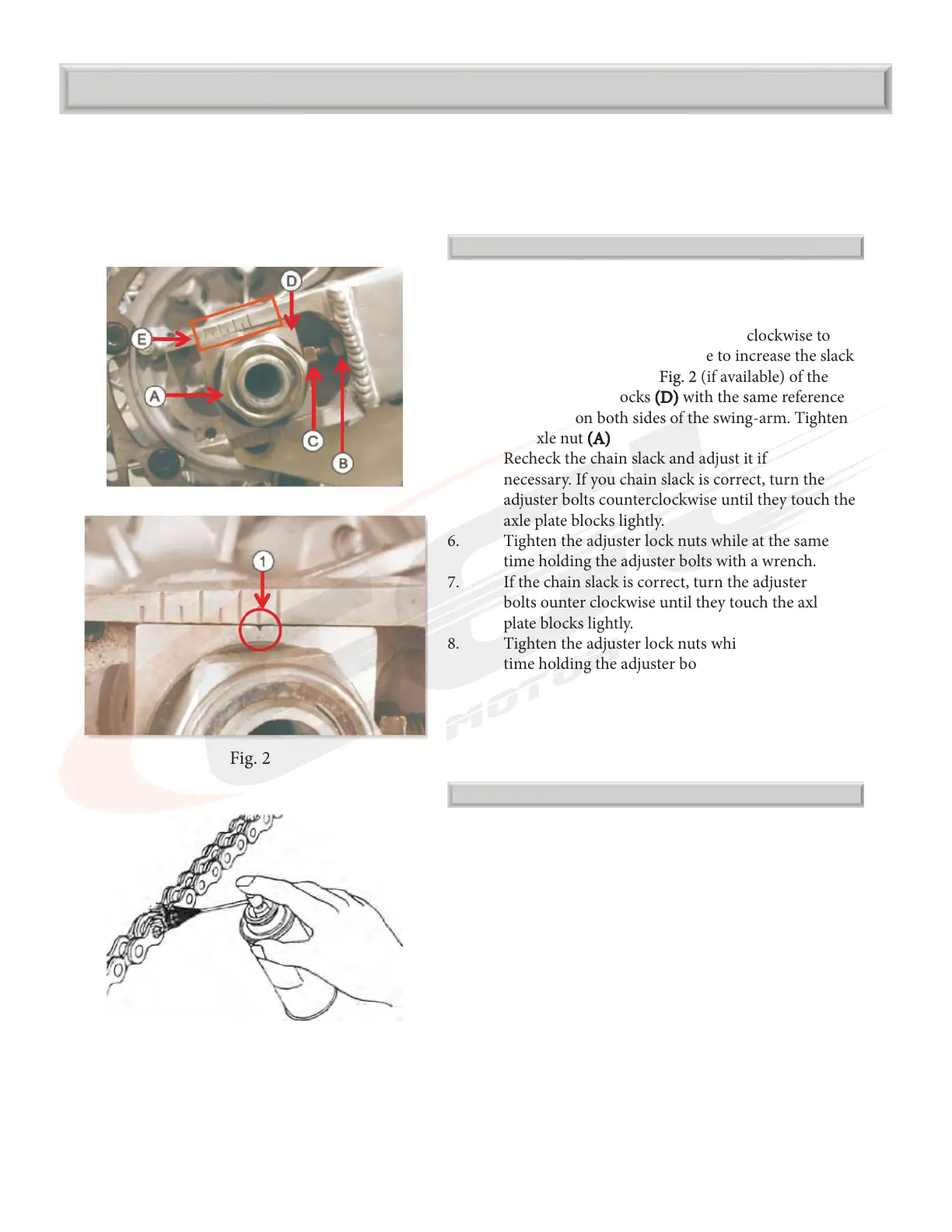

1. Loosen the rear axle nut (A)(A)

2. Loosen the adjuster lock nuts (B)(B) on both the

le and right side of the swing-arm.

3. Turn the adjusting bolts (9 counter-clockwise to

decrease the slack or clockwise to increase the slack.

4. Align the marks (1)(1) in Fig. 2Fig. 2 (if available) of the

adjusting plate blocks (D)(D) with the same reference

marks (E)(E) on both sides of the swing-arm. Tighten

the axle nut (A)(A)

5. Recheck the chain slack and adjust it if

necessary. If you chain slack is correct, turn the

adjuster bolts counterclockwise until they touch the

axle plate blocks lightly.

6. Tighten the adjuster lock nuts while at the same

time holding the adjuster bolts with a wrench.

7. If the chain slack is correct, turn the adjuster

bolts ounter clockwise until they touch the axle

plate blocks lightly.

8. Tighten the adjuster lock nuts while at the same

time holding the adjuster bolts with a wrench.

Fig. 1

Fig. 2

CHECKING BRAKE PADSCHECKING BRAKE PADS

DRIVE CHAIN LUBRICATION DRIVE CHAIN LUBRICATION

Commercially prepared chain lubricants may be purchased

at many motorcycle shops and should be used instead of mo-

tor oil. Chain lube or gear oil (80w or 90w) is recommended.

Saturate each joint so that the lubricant penetrates the space

between each surface of the link plates and rollers.

Loading...

Loading...