0 34LPM

120

32

87

1

3

A-coding

In water. Set point accuracy: ±15%.

Repeatability (not considering the viscosity change of liquids): ±10%.

Technical Specications

PPA (Polyphthalamide)

AISI 302 stainless steel

114mm

2

25bar

0°C to 100°C | 140°C @1h

G 1/2” female (BSP - Parallel)

NBR (nitrilic rubber) O’Ring

M12 male plug (2 pins)

M12 female connector NOT included

IP66

Reed Switch 20W/VA (NA SPST)

200g

Body

Spring

Internal clearance

Maximum operating pressure

Operating temperature range

Inlet/outlet port

Sealing

Output connection

Enclosure rating

Electrical contact

Weight

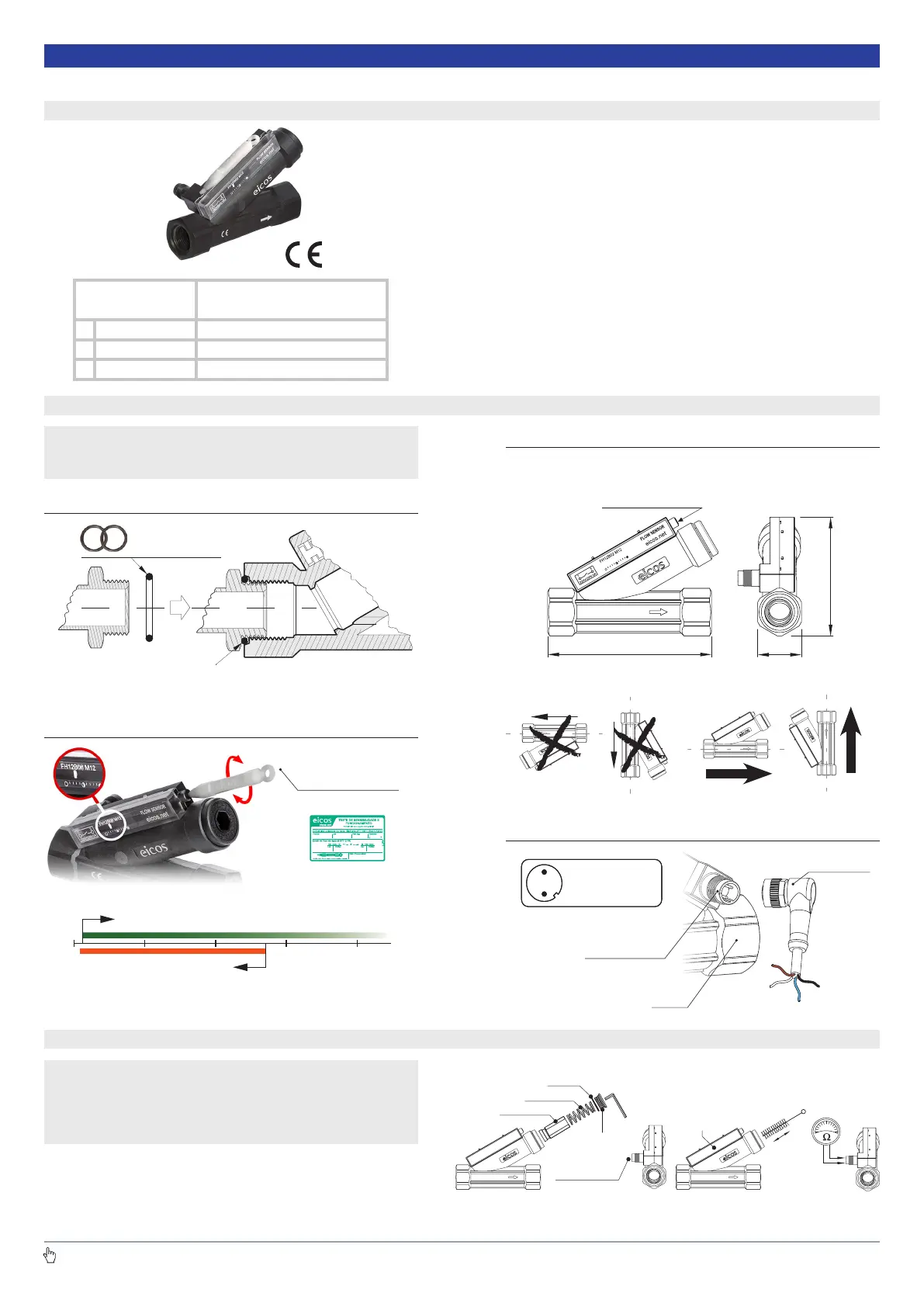

Suitable for Detection of Medium Flows

Fluid ow through the sensor triggers precise displacement of a magnetic piston acting on an electrical contact (Reed Switch).

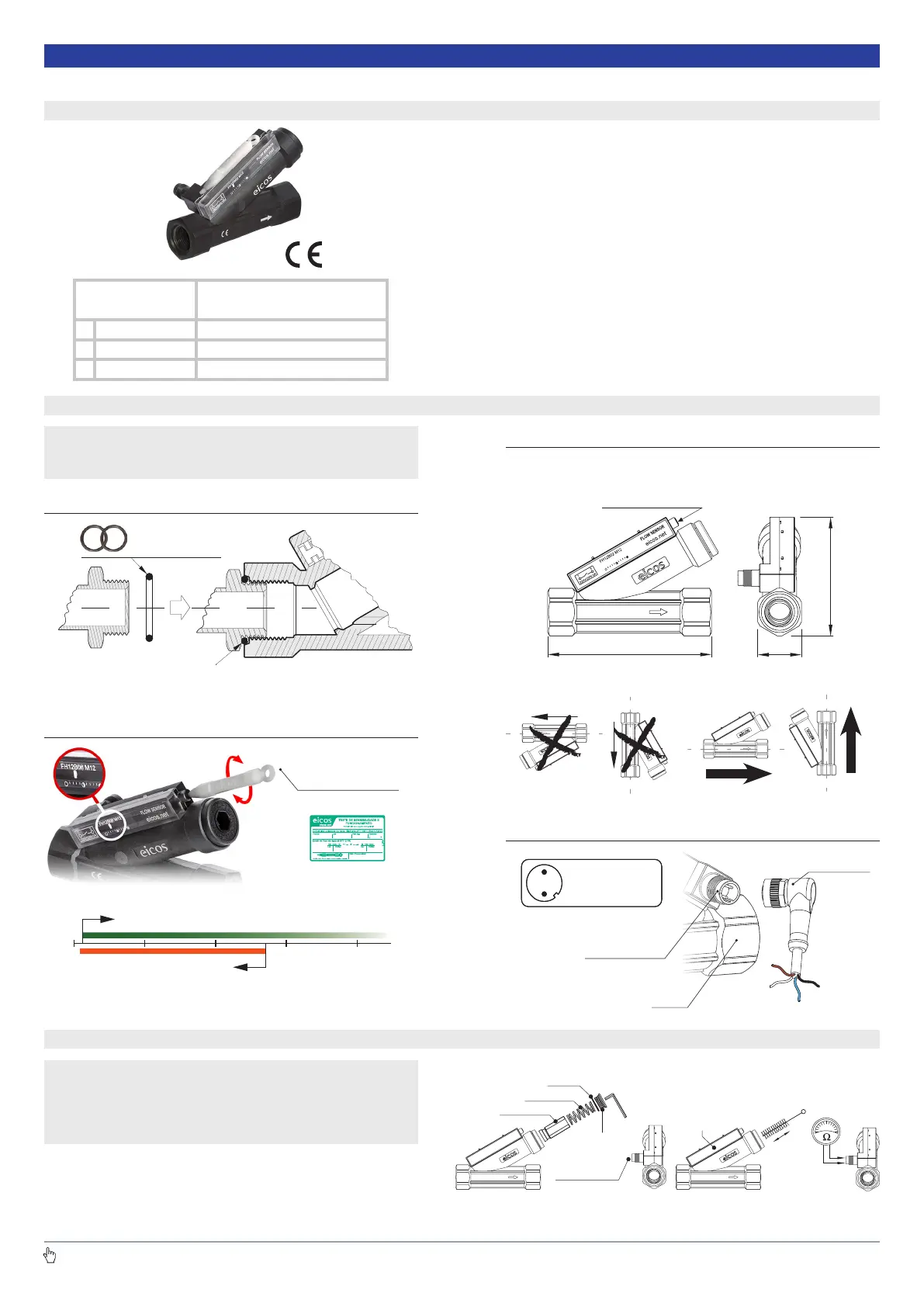

Installation

• In applications without excessive vibration;

• Minimum distance of 20mm from any ferrous surface;

• Mounting with parallel port connection and O’Ring.

Mounting

Dimensions in millimeters.

Sealing

Flow Rate Sensitivity Adjustment

Results of the

sensitivity test

(xed in the package)

Allen wrench to

adjust the sensitivity

(included)

Maintenance

1. Open the plug, remove the spring and clean using a brush if

there is encrustation;

2. Mount the sensor again as illustrated beside;

3. Test the electrical contact using an ohmmeter, moving the

magnetic piston.

On datasheets.eicos.us available technical specications

Flow Switches and Level Switches for liquids

Model

Actuation Range in Water

(in LPM)

FH12B02-M12 From ~0.3 to ~17

FH12B04-M12 From ~0.6 to ~29

FH12B06-M12 From ~1.0 to ~34

O’Ring (NBR) for sealing

Parker code 2-116

(included)

GAS (BSP) Thread

The sealing is made on the ring.

It’s not necessary sealant tape or

over tightening

Check compatibility with NPT

thread on datasheets.eicos.us

Scale

Brush

Allen

Wrench

10mm

Plug

Piston

Spring

O’Ring

Output plug

M12 plug

1

3

A-coding

Hex screw for

sensitivity adjustment

CORRECT

FLOW

FLOW

WRONG

M12 female

connector

Electrical Connection

FLOW INCREASE - ON

FLOW DECREASE - OFF

Male M12 plug

2 pins

Flow

Switch

3-BK

1-BR

Loading...

Loading...