General Regulaons

8

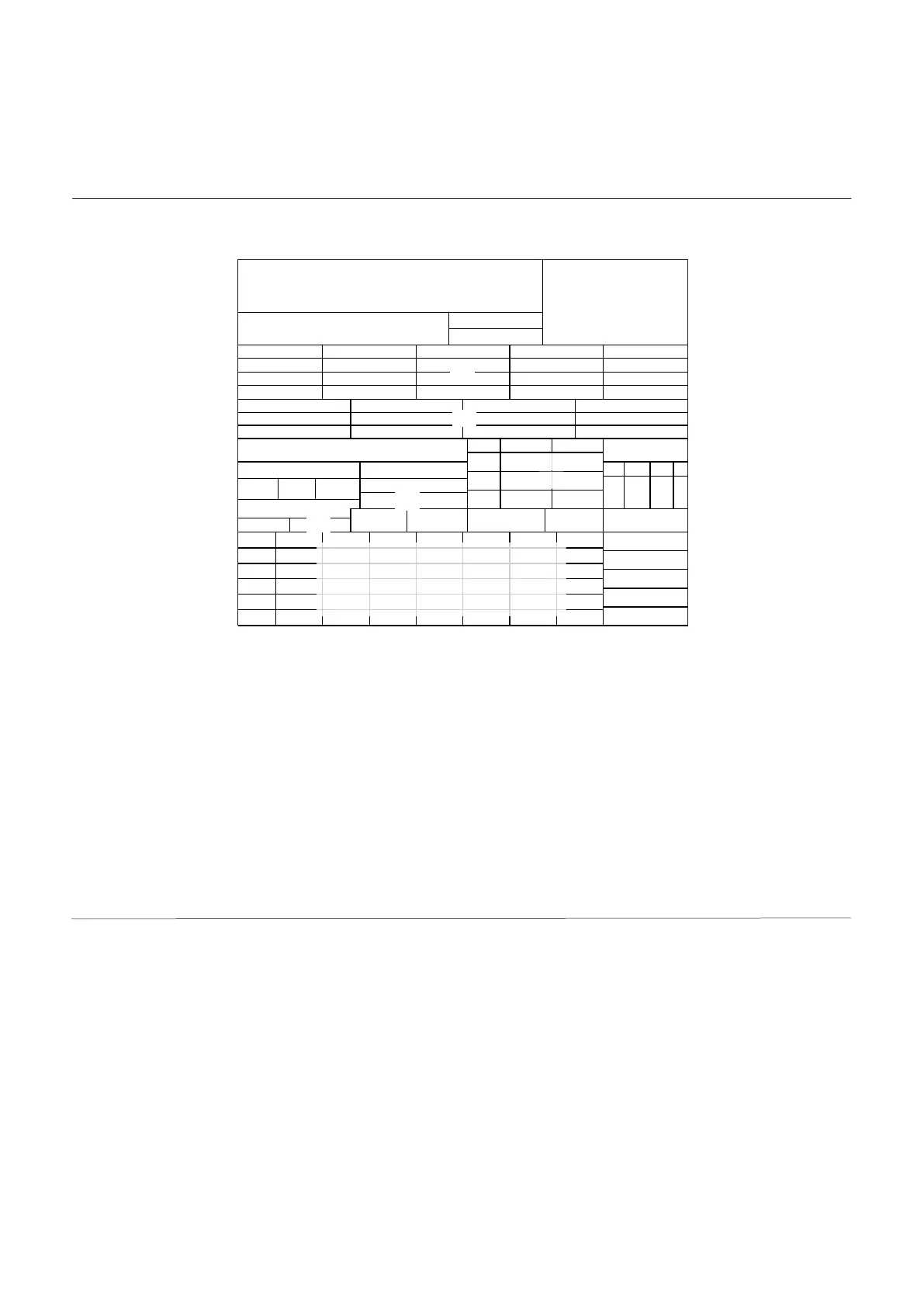

Data Plate

Operang principle

8

Symbols used on the data plate

Legend :

1 Brand

2

Country of origin

3 Boiler model - Serial number

4 Commercial reference

5 Certication number

6 Destination country - Gas category

7 Gas setting

8 Installation type

9 Electrical data

10 Factory settings

11 Maximum water pressure

12 Boiler type

13 NOx class / Efciency

14 Input rating nominal heating

15 Power output heating

16 Gases which may be used

17 Ambient operating temperature

18 Max. central heating temperature

26-05-2015

S/N 0000000KE000000000000

00

100% min.

η η

= =

MAX MIN

Q(Hi)

P

P

60/80C

30/50C

gas

mbar

gas

mbar

gas

mbar

0000000KE000000000000

0000000KE000000000000

0000000KE000000000000

6

0000000KE000000000000

5

0000000KE000000000000

4

0000000KE000000000000

3

0000000KE000000000000

2

0000000KE000000000000

1

PCT

0000000 KE 000000000000

26-5-2015 13:07:34

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

General regulations

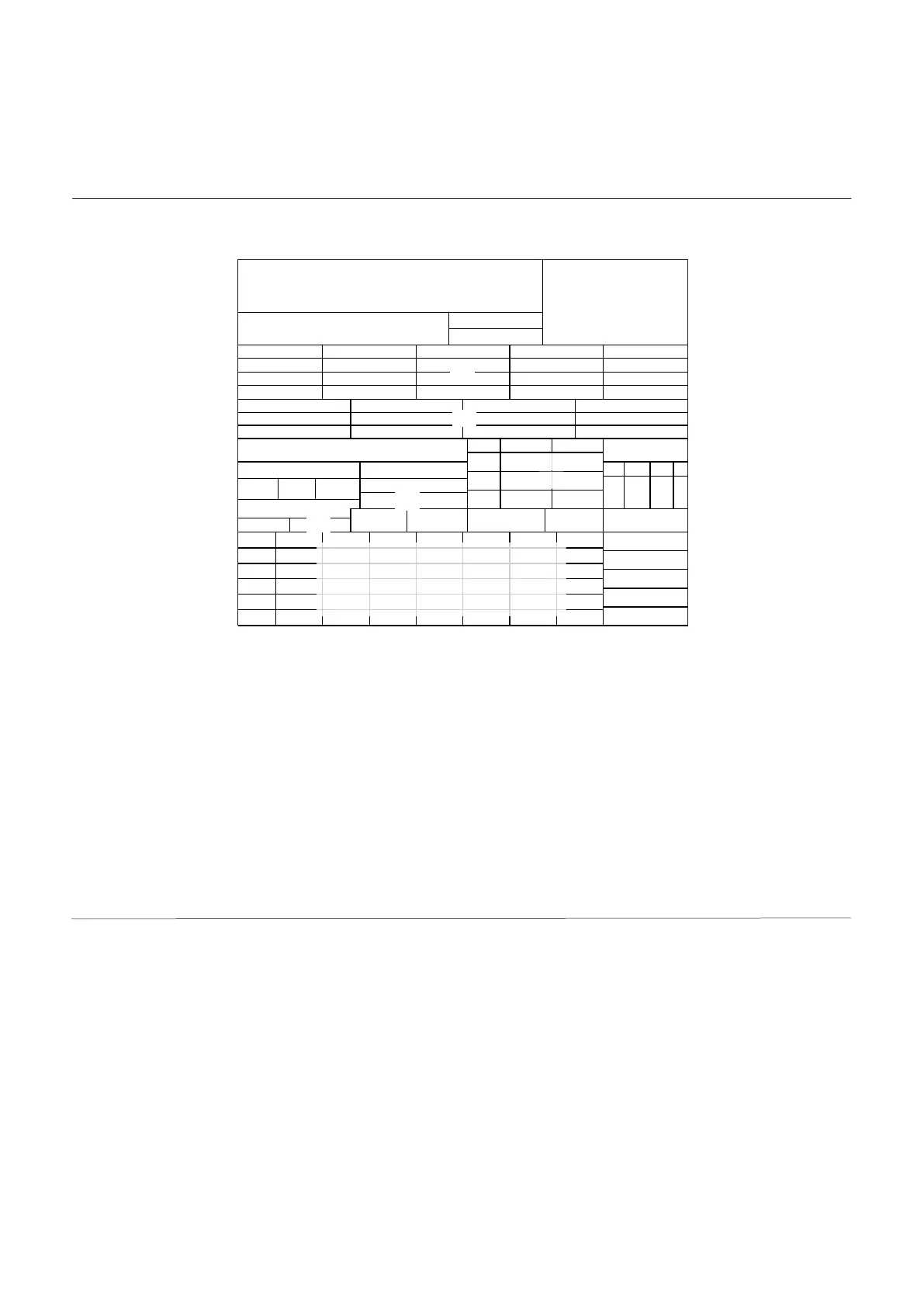

Data plate

Symbols used on the data plate

1 Brand

2

Country of origin

3 Boiler model - Serial number

4 Commercial reference

5 Cercaon number

6

Desnaon country

- Gas category

7 Gas seng

8 Installaon type

9 Electrical data

10 Factory sengs

11 Maximum water pressure

12 Boiler type

13 NOx class / Eciency

14 Input rang nominal heang

15 Power output heang

16 Gases which may be used

17 Ambient operang temp.

18 Max. central heang temp.

Operang principle

The TRIGON XL is a fully modulang

boiler.

The control unit of the boiler adapts

the modulaon rao automacally

to the heat demand requested by

the system. This is done by control-

ling the speed of the fan. As a result,

the mixing system will adapt the gas

rao to the chosen fan speed, in

order to maintain the best possible

combuson gures and therewith

the best eciency.

The ue gases created by the com-

buson are transported downwards

through the heat exchanger and

leave the boiler at the boom into

the chimney connecon.

The return water from the system

enters the boiler in the lower sec-

on, where is the lowest ue gas

temperature in the boiler.

The water is being transported up-

wards through the heat exchanger,

in order to leave the boiler at the

ow connecon. The cross ow

working principle (water up, ue gas

down) ensures the most ecient

combuson results.

The LMS14 control unit can control

the boiler operaon based on:

• Boiler control

(stand alone operaon);

• weather compensated operaon

(with oponal outdoor sensor);

• with 0-10V external inuence

(temperature or capacity) from a

building management system.

Loading...

Loading...