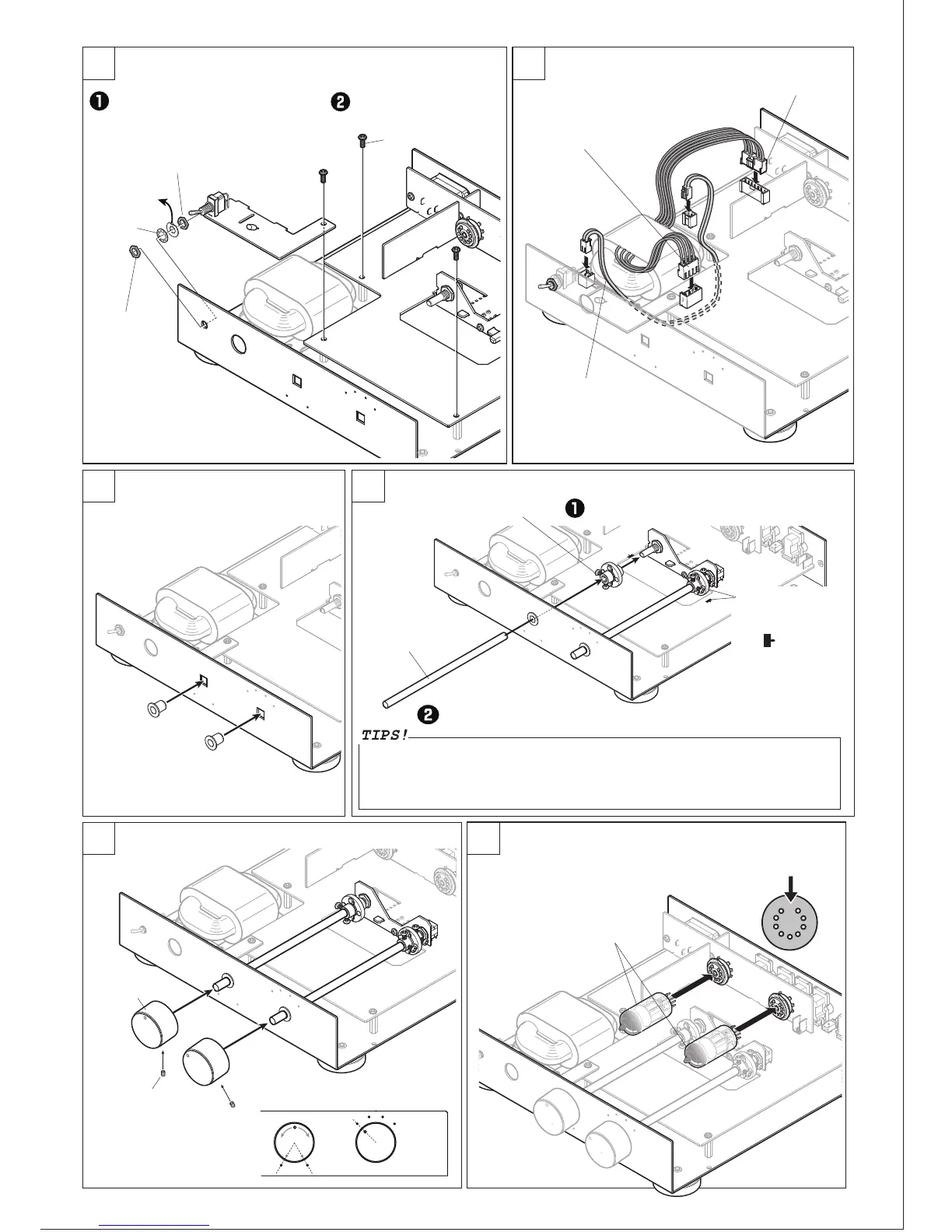

9

6 7

8

10

11

9

Install UNIT-4.

Install flange bushings.

Nut (Thread till end of the shaft)

This washer

is not used.

Claw washer

Nut

UNIT-4

Binding screw small

3pcs

7-pin connector

4-pin connector

Connector cable

Push hard into the square holes.

Flange bushing

2pcs

Metal shaft Long

2pcs

Ceramic coupling 2pcs

Install metal shafts.

Install knobs.

Knob

2pcs

Screw for knob

Install vacuum tubes

to the socket.

Vacuum tube

12AU7

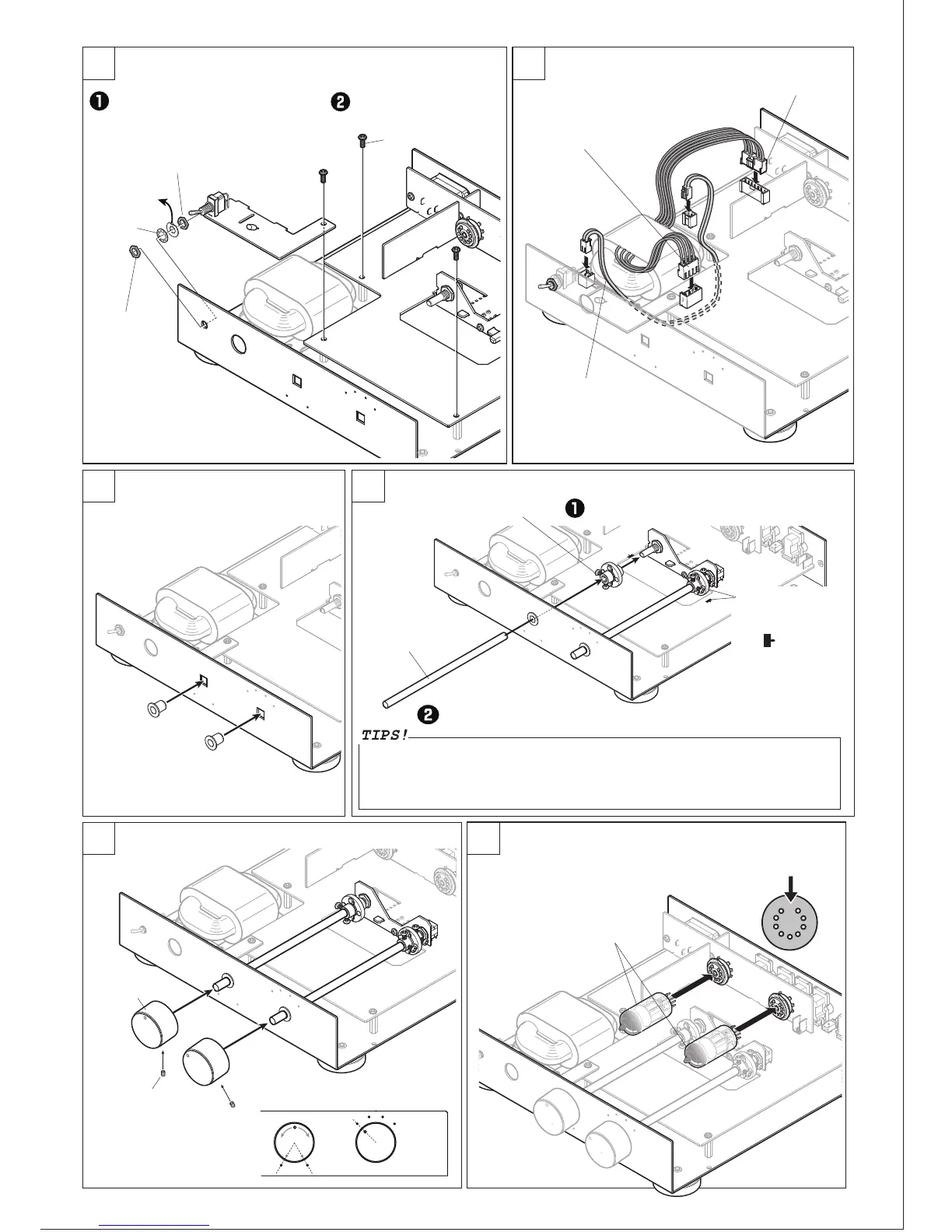

Remove the nut and washer from the

toggle switch. Install Unit-4 to the

bottom chassis. Thread the remaining

nut on the toggle switch from the front.

Fix UNIT-1 and UNIT-4 with

binding screw small.

Install the cables with connectors as shown.

Push the cables with connectors

into their sockets between the

transformer and UNIT-1.

Set ceramic couplings to the shafts of the

volume and the rotary switch.

Insert the metal shafts into the ceramic coupling. Once fully seated, back

the shaft out approx. 1mm from the coupling and tighten the set screws.

Leaving 1-2mm

clearance between the

knob and chassis, fix the

knobs with attached

screws to each shaft.

Align the knobs to the indicators on

the chassis.

Check if the pins are correctly

aligned to the socket.

Push in the white

disk part of the

ceramic coupling to

the position

indicated on the PCB

and fix with the

screws.

8500-02

There must be a clearance between the shaft and the flange bushings in order for the shaft to rotate

smoothly. However, due to this allowance the shaft may not sit firmly in the bushing. Adding a small

amount of grease between the bushing and shaft is recommended. Select a high viscosity grease

(Catagory 3 or higher) for best results. Mixing baby powder at a 1:1 ratio with a lower viscosity

grease (below Catagory 3) can be substituted if needed.

Loading...

Loading...