ELEKTROGAS – TECHNICAL MANUAL

12-13

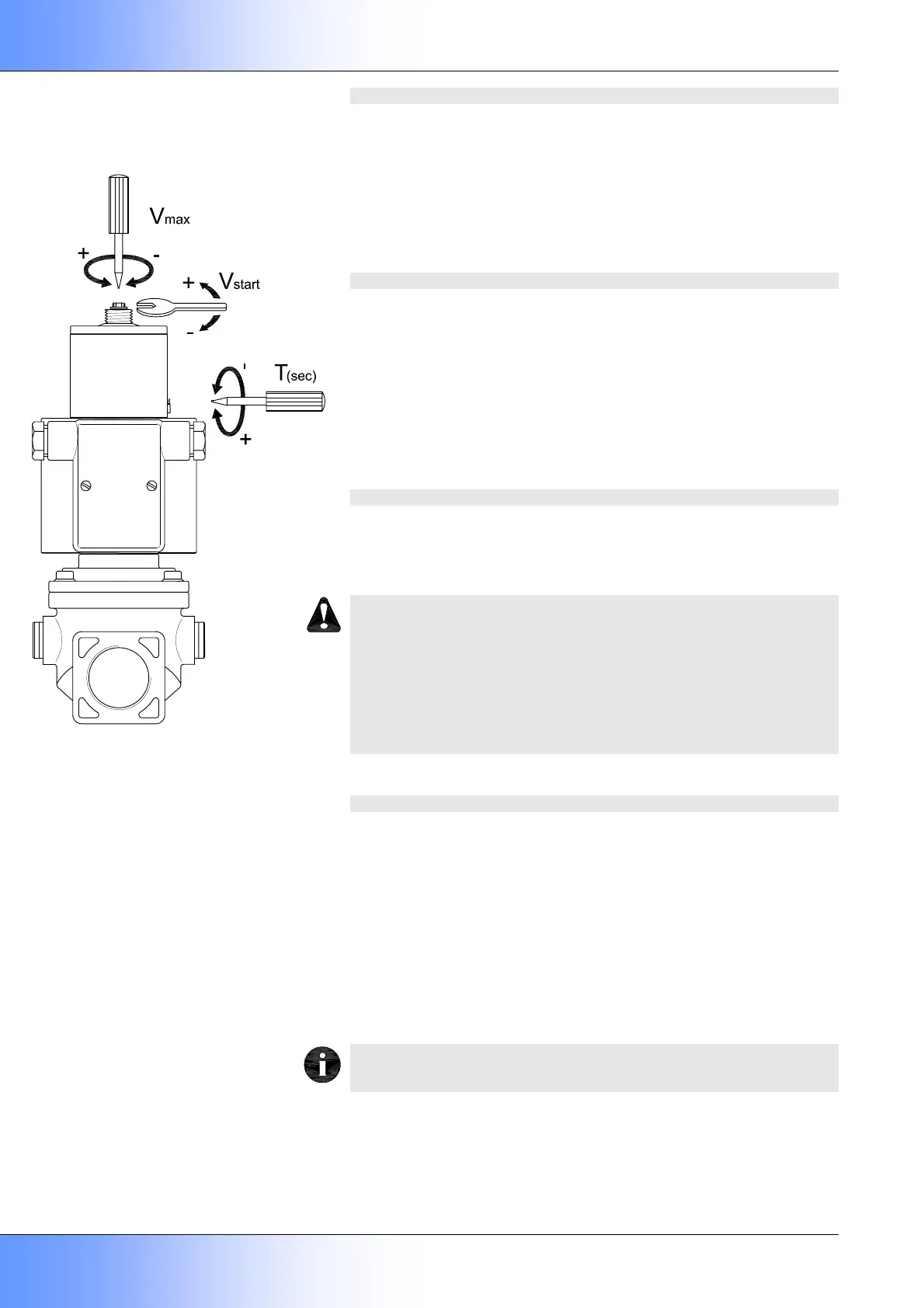

FAST STROKE ADJUSTMENT (Vstart)

Fast flow section may be adjusted:

1. Remove plastic cap.

2. Using an hexagonal wrench, turn the outer screw clockwise to decrease

or counter-clockwise to increase the initial fast stroke.

3. When adjustment is completed, screw back the plastic cap.

NOTE: in the DN65 and DN80 models the minimum adjustable stroke is 3mm.

FLOW RATE ADJUSTMENT (Vmax)

Flow rate may be adjusted from 0 cubic meters/h up to the maximum

admitted:

1. Remove plastic cap.

2. Keeping the outer screw fixed, use a screw driver to turn the internal

screw clockwise to decrease or counter-clockwise to increase flow rate

(factory setting is max. flow rate).

3. When adjustment is completed, screw back the plastic cap.

NOTE: the flow rate regulation can not be lower than the fast flow section.

OPENING TIME ADJUSTMENT (T)

To regulate opening time, turn the screw located on the side of the brake. One

fourth of a turn clockwise increases opening time by 2÷3 s, up to a maximum

of about 25 s (slow run).

Factory setting is about 12÷14 s.

WARNING

Perform the fast stroke adjustment before of the flow rate adjustment.

Make sure that capacity adjustments are made while burner is working.

Check the regulation is not changed during reassembly.

Adjustments below 40% of capacity are unadvisable because they may

cause turbulence.

Fig. 8

COIL REPLACEMENT

Before to start with coil replacement, make sure it is the cause of failure.

To perform coil replacement do the following:

1. Make sure an identical one spare part is available.

2. Switch off power supply and remove the box cover.

3. Disconnect the wires from terminal board.

4. Unscrew the hydraulic brake.

5. Extract and replace coil.

Reassemble following the inverse sequence. Make sure that two O-ring below

the brake are in their seat.

To maintain a good performance of the system, almost once a year, an

external inspection of the valve is recommended.

Loading...

Loading...