KEEP WORKiNG

Keep Working

KEEP WORKiNG

21

Si6130XP Si7160XP

Si7175XP Si7200XP

8. MAINTENANCE & TROUBLESHOOTING

TROUBLESHOOTING

The device is constructed for long service with a minimum of maintenance. Long term satisfactory operation depends on the

correct care of the device and regular cleaning.

Cleaning – first remove the power plug

Regularly clean the device using a soft cloth, preferably after every use. Keep the ventilation slots free of dust and dirt. If

the dirt cannot be easily removed, use a soft cloth dampened with soapy water. Never use solvents such as petrol, alcohol

etc. These solvents can damage plastic parts.

Lubrication

The device requires no additional lubrication.

Diagnose

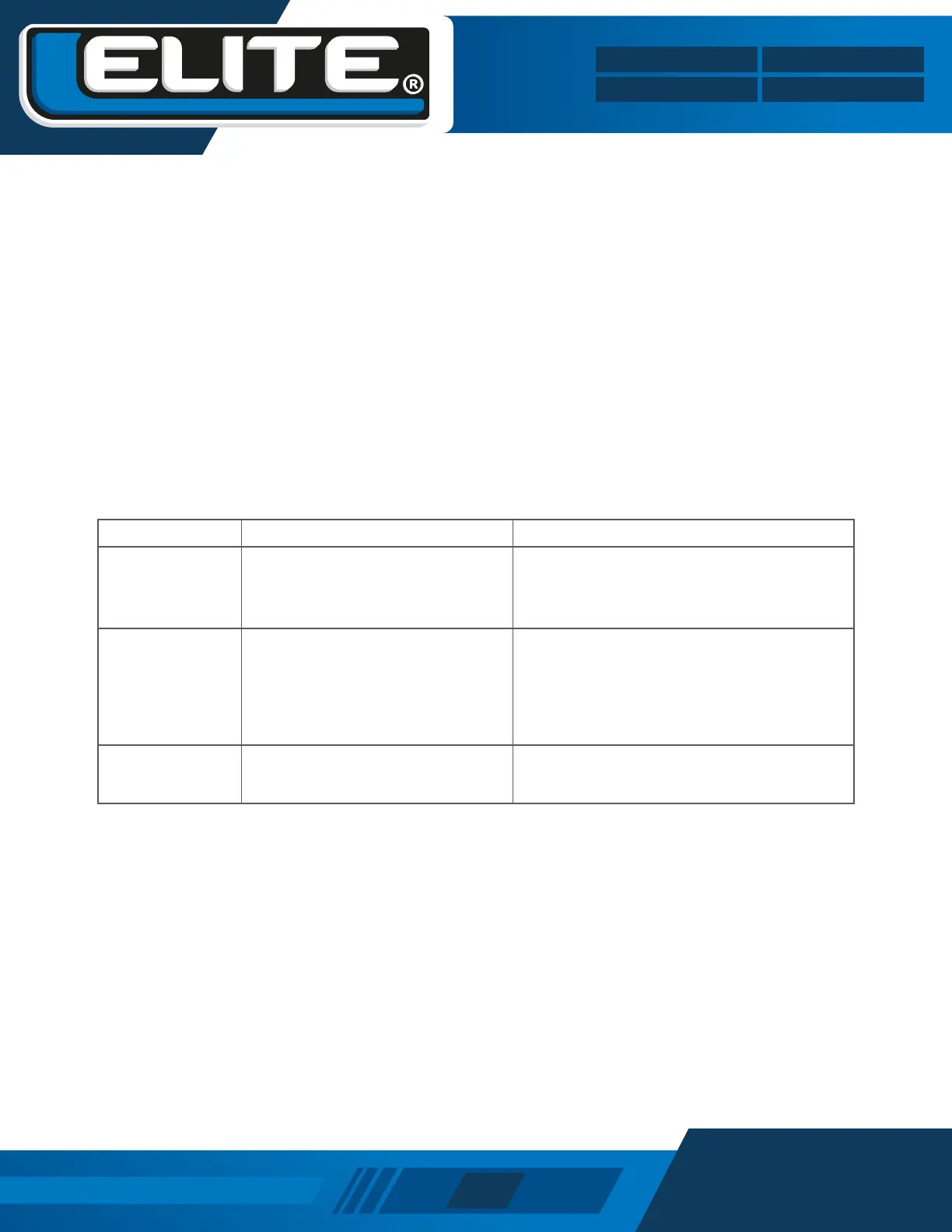

If the machine can’t work normally, stop using it at once and use the following table to find the possible reason and solution.

If it’s not the reasons listed above, send the welding machine to our service center or responsible vender

for help.

Warning: Never try to fix the welding machine yourself, never open the enclosure. We are not responsible for

any accident resulting from your improper dealing with the machine.

No supply.

Improper fuse or breaker.

Thermal protection actuated.

Check the power connection.

Replace an appropriate fuse or breaker.

Waiting for about 5 minutes.

POSSIBLE REASONS

SOLUTION

FAULT

No output

Poor connection Check the grounding clamp to ensure good

connection. Clean the rust or paint if any.

Move the clamp to be closer to the position

to weld

Low current

Bad electrode. Change a new electrode

Línea de soldadura

defectuosa

Grounding clamp too far from the

position need to weld.

Loading...

Loading...