3 EWTR/HR/PR 910 12/96 ing

in 0 or 5 only, or in all 10 digits.

hdd = n : e.g. 070, 071, 072 etc. (if with-

out decimal point) or 70.0, 70.1, 70.2 etc.

(if with decimal point);

hdd = y : e.g. 070, 075, 080, etc. (if with-

out decimal point) or 70.0, 70.5, 71,0, etc.

(if with decimal point). Useful when mea-

suring values varying rapidly (e.g. %R.H.).

tAb: tAble of parameters.

This shows the configuration of the para-

meters as set in the factory; can not be

modified (for factory identification and di-

agnostic purposes only).

PROPORTIONAL CONTROL

In the event that the factory set parameter

values in a PID temperature controller do

not give optimum results, the following

steps may be followed to enhance the op-

eration for each specific application:

» select a value for Setpoint which will keep

the temperature swing within acceptable

limits, for example 10% below the normal

operating temperature;

» set the switching differential (“d1”) at 3%

of the setpoint temperature;

» start the system and wait for the temper-

ature swings to become constant;

» check the process temperature (use a

data recorder if possible) at regular inter-

vals; determine the time between two suc-

cessive temperature peaks (Tu) as well as

the total temperature swing (dT).

Parameters “Pb”, “It”, “dt” and “Ct” can

now be calculated as follows:

Pb = 2xdT; It = Tu/2; dt = Tu/8; Ct = Tu/20.

Additional fine tuning of the above para-

meters may be tried, keeping in mind how-

ever the following:

- the “Proportional action” activates the

output in direct proportion to the shift in

stable system temperature;

- the “Derivative action” effects the output

depending on the speed of temperature

change;

- the “Integral action” activates the output

in proportion to the continuous integral cal-

culation of the deviation values.

As a result:

a) an increase in the proportional band

width reduces the temperature swing, but

increases the shift in stable system tem-

perature;

b) an excessive reduction of the propor-

tional band width reduces deviation, but

will also make the system less stable;

c) an increase in the derivative time re-

duces temperature swings when the sys-

tem has become stable, but may cause

wider temperature swings and increased

deviation from setpoint;

d) an increase in the integral time reduces

the deviation between setpoint and system

value when system has become stable;

e) a weak integral action always has a tem-

perature deviation which, in general, can

be eliminated by reducing the proportional

band width and by increasing first of all the

derivative action, then the integral action.

INSTALLATION

The instrument is designed for flush panel

mounting; the required panel cut-out is

67x67 mm (2.64x2.64"). Insert the instru-

ment from the front and tighten from the

rear with the two mounting brackets pro-

vided.

The ambient temperature around the in-

strument should be kept between –5 and

65 °C (23 and 149 °F). Select a location

which will not be subject to high humidity

or condensation and allow some ventila-

tion to provide cooling to the instrument.

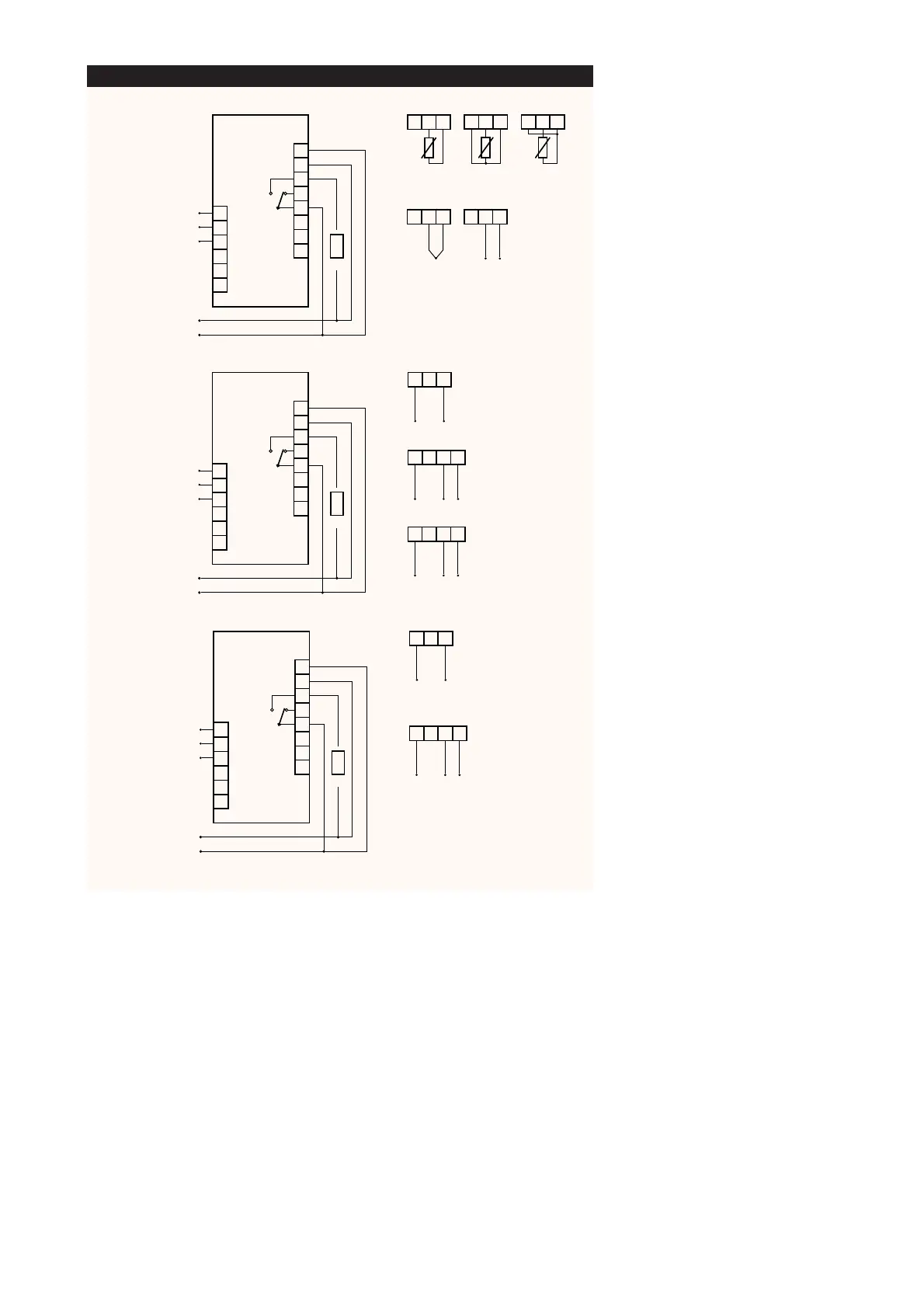

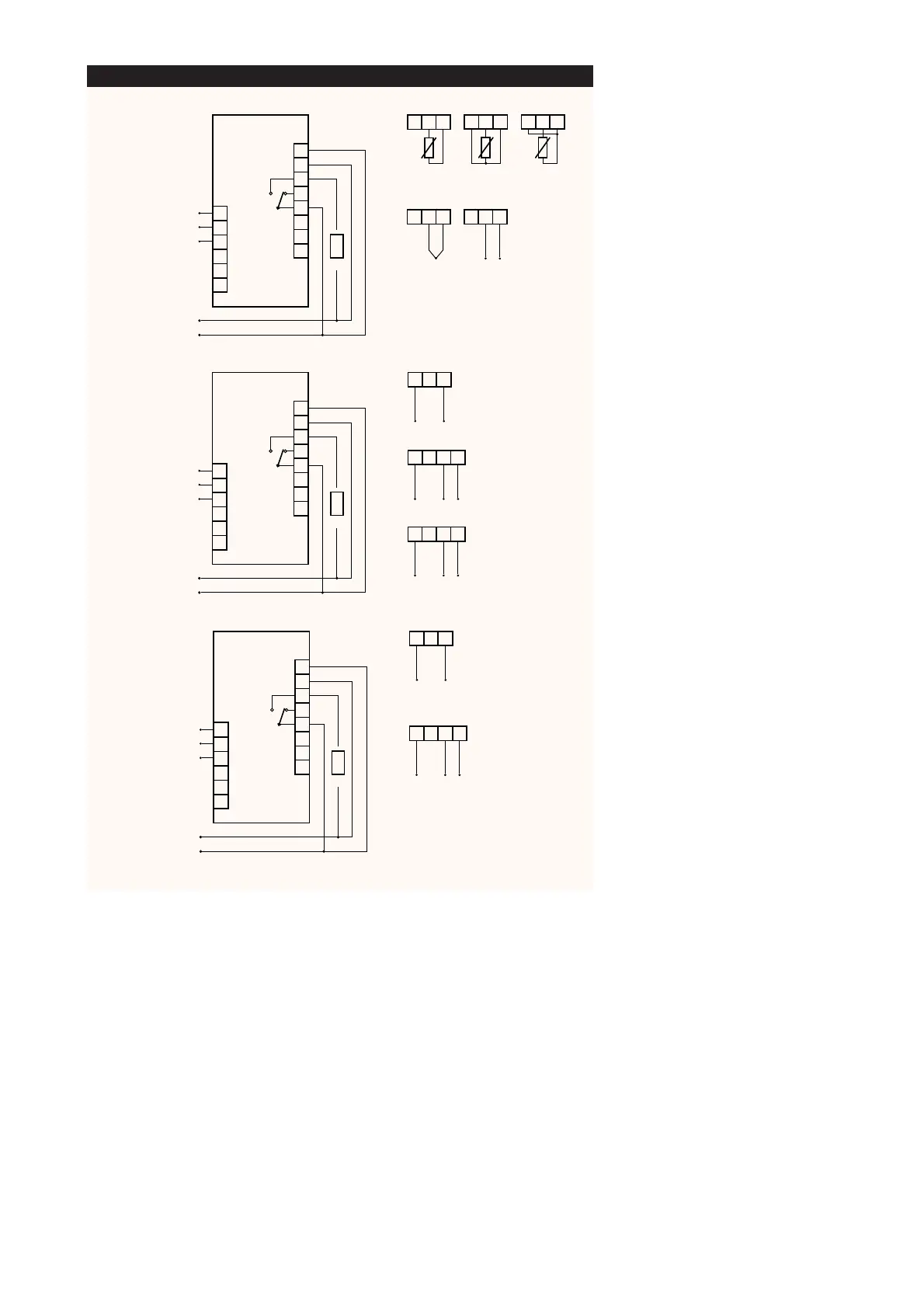

ELECTRICAL WIRING

Two quick-disconnect terminals are pro-

vided for easy and convenient wiring, even

before the instrument is actually installed.

Make sure that the power supply corre-

sponds with the rating shown on the in-

strument; the power supply must be kept

within plus or minus 15% of the nameplate

voltage.

Separate the wiring of the input signals

from those of the power supply and

switched output wiring.

The relay output contacts are voltage free

and independent ; do not exceed the re-

sistive rating of 8 Amp at 250 Vac. For larg-

er loads, please use an external contactor

or relay.

ERROR ANNOUNCIATION

Any sensor input defect will be displayed

as follows: “---” in case of shorted sensor;

“EEE” in case of sensor break, or sensor

absence.

The “EEE” error message also appears in

Loading...

Loading...