3. When a clearance of 1-1.5 mm has been achieved between the wheels and the flange, the

trolley can be installed on the beam and the nuts fastened and secured by the split pin.

4. Ensure that endstops are fitted to the runway, so that the trolley cannot run off.

5. Before applying a load to the trolley, make a test-run to be sure it runs smoothly back and forth

along the entire runway.

6. The hoist may now be hooked on and the combination put into operation.

V. Maintenance and inspection

The trolley is maintenance free.

VI. Specification

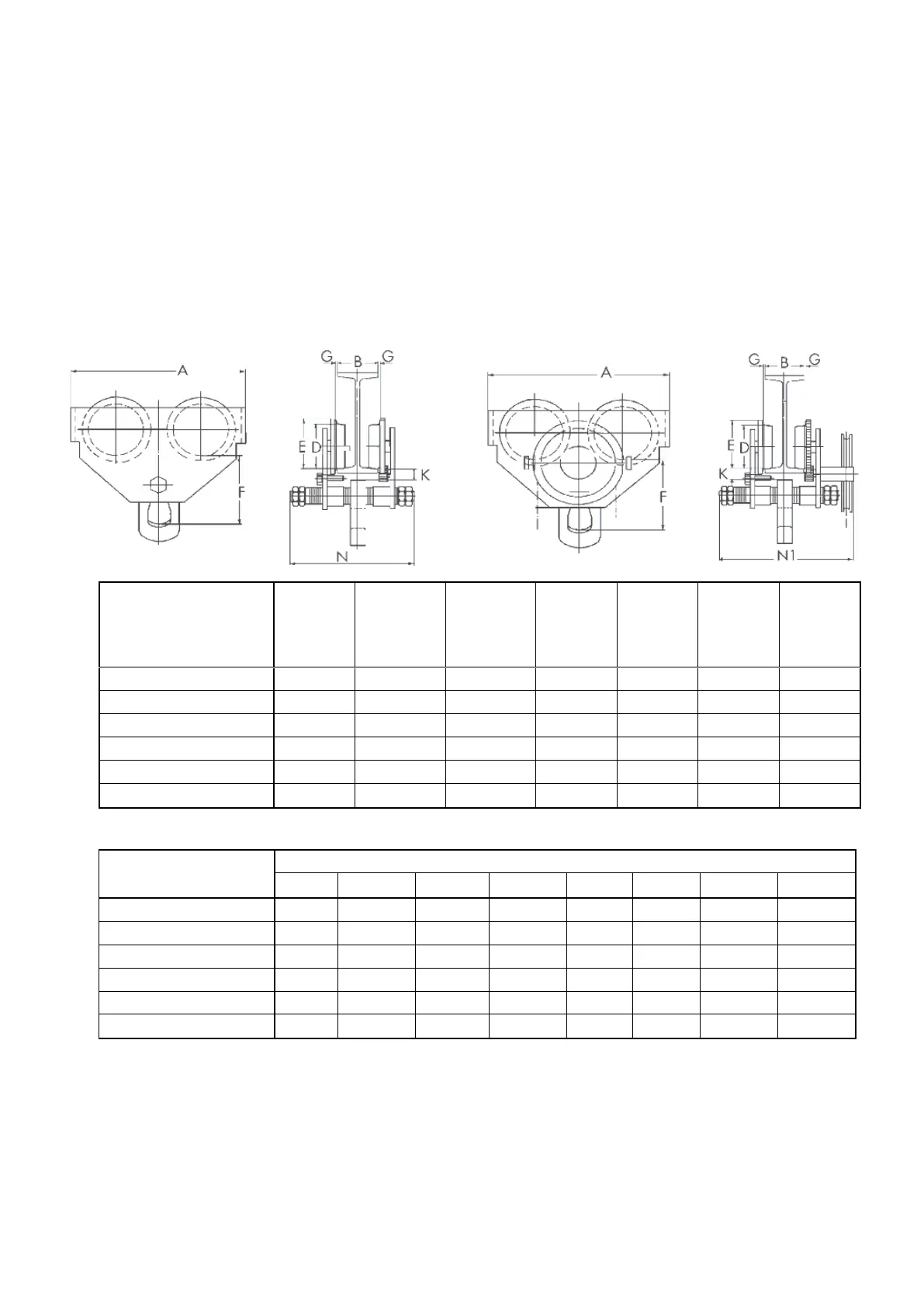

Adjustable

beam width

PT B (mm)

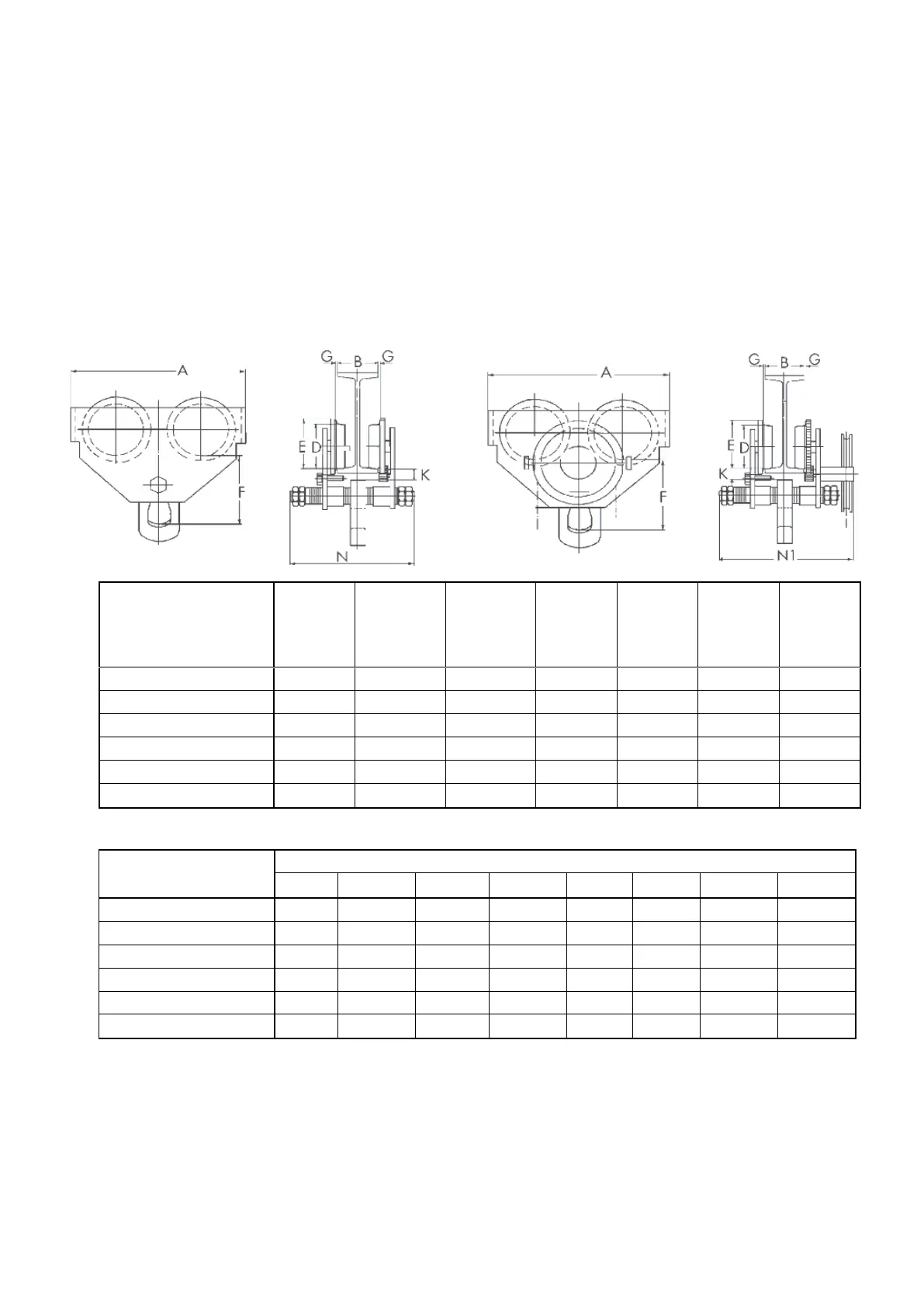

Adjustable

beam width

GT B (mm)

Loading...

Loading...