Instruction Manual

D102175X012

EZ-C, ET-C, and EWT-C Valves

July 2017

8

Do not remove a stuck bonnet by pulling on it with equipment that can stretch or store energy in any other manner. The

sudden release of stored energy can cause uncontrolled movement of the bonnet.

D To avoid personal injury or damage to the seating surface caused by the valve plug and stem assembly dropping from

the bonnet after being lifted out of the valve body, observe the following instructions.

4. When lifting an EZ‐C bonnet, temporarily install a valve stem locknut on the valve stem. This locknut will prevent

the valve plug and stem assembly from dropping out of the bonnet.

5. When lifting an ET‐C or EWT‐C bonnet, be sure the plug and stem assembly and cage remain in the valve body.

WARNING

To avoid possible personal injury, review your process shutdown procedures to be sure process pressure is not applied to

the valve for the following procedure.

6. Hex nuts (key 16) attach the bonnet to the valve body (key 1). Loosen these nuts or cap screws approximately 3 mm

(1/8 inch). Then, loosen the body‐to‐bonnet joint by either rocking the bonnet or prying between the bonnet and

valve body. Work with a prying tool around the bonnet until the bonnet loosens.

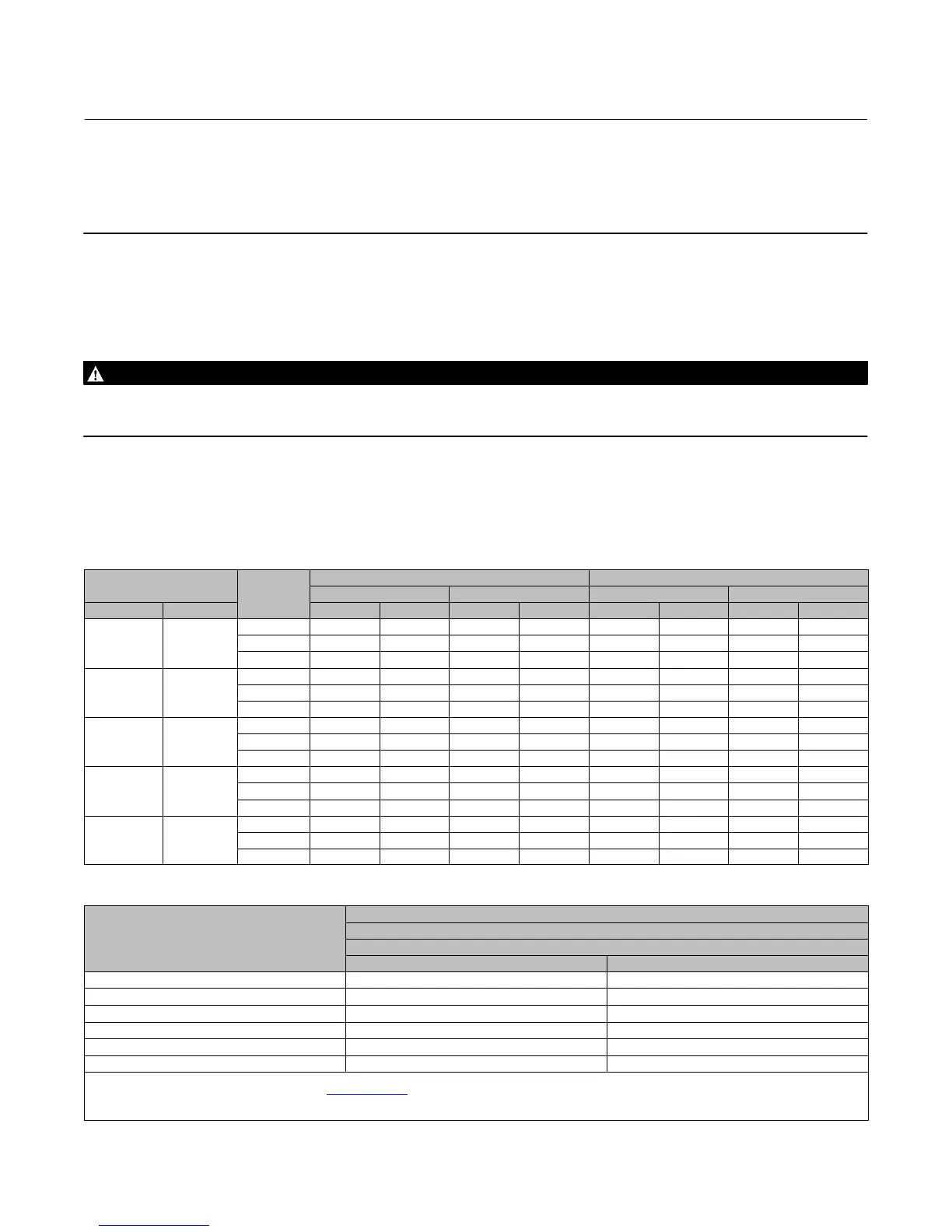

Table 3. Recommended Torque for Packing Flange Nuts

VALVE STEM DIAMETER

PRESSURE

RATING

GRAPHITE PACKING PTFE PACKING

Minimum Torque Maximum Torque Minimum Torque Maximum Torque

mm Inch NSm Lbf‐in NSm Lbf‐in NSm Lbf‐in NSm Lbf‐in

9.5 3/8

150 3 27 5 40 1 13 2 19

300 4 36 6 53 2 17 3 26

600 6 49 8 73 3 23 4 35

12.7 1/2

150 5 44 8 66 2 21 4 31

300 7 59 10 88 3 28 5 42

600 9 81 14 122 4 39 7 58

19.1 3/4

150 11 99 17 149 5 47 8 70

300 15 133 23 199 7 64 11 95

600 21 182 31 274 10 87 15 131

25.4 1

150 19 169 29 254 9 80 14 120

300 26 226 38 339 12 108 18 162

600 35 310 53 466 17 149 25 223

31.8 1‐1/4

150 27 238 40 357 13 113 19 169

300 36 318 54 477 17 152 26 228

600 49 437 74 655 24 209 36 314

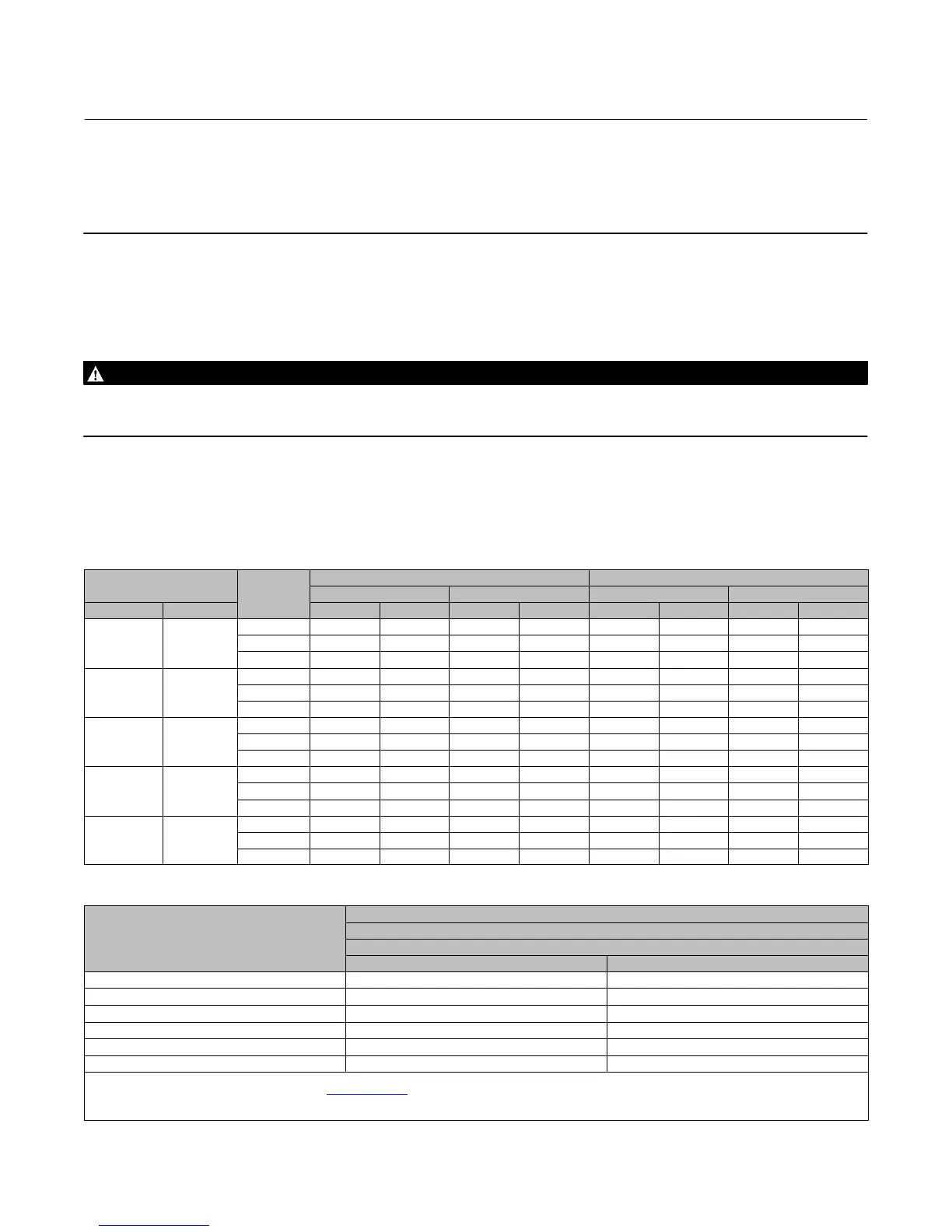

Table 4. Body‐to‐Bonnet Torque Guidelines

VALVE SIZE, NPS

BOLT TORQUES

(1)

Bolt Material

(2)

B8M

(3)

or S20910 (XM‐19)

(4)

NSm Lbf‐ft

1 122 90

1-1/2 or 2 91 67

3 163 120

4, 6X4, or 8X4 258 190

6, 8X6, or 12X6 522 385

8 or 10X8 712 525

1.Determined from laboratory testing.

2. For bolting materials not listed in table 4, contact your Emerson sales office or Local Business Partner for torque information.

3.SA193‐B8M strain hardened.

4.Hot rolled.

Loading...

Loading...