Turn off water supply before starting.

Installation must comply with all state and local laws and regulations.

Property Damage: Do not extend the lines farther

than the 16" provided. Ensure tube(s) and “Y”

connnector are securely fit.

Personal Injury: Do not locate filter above an

outlet or other electrical device. Install head and bracket

so that connections require no stretching, kinking or

pinching of tubing.

It is normal for approximately 2 oz. of water

to discharge when filter is removed.

Property Damage: Tube runs need to form to the

cabinet’s contours to allow storage space with no sharp

bends. Tubes need clean, perpendicular,

burr-free cuts to ensure a true fit.

a

c

From water

supply line

To dispenser

d

INSTALLING FILTRATION SYSTEM

b

From water

supply line

To dispenser

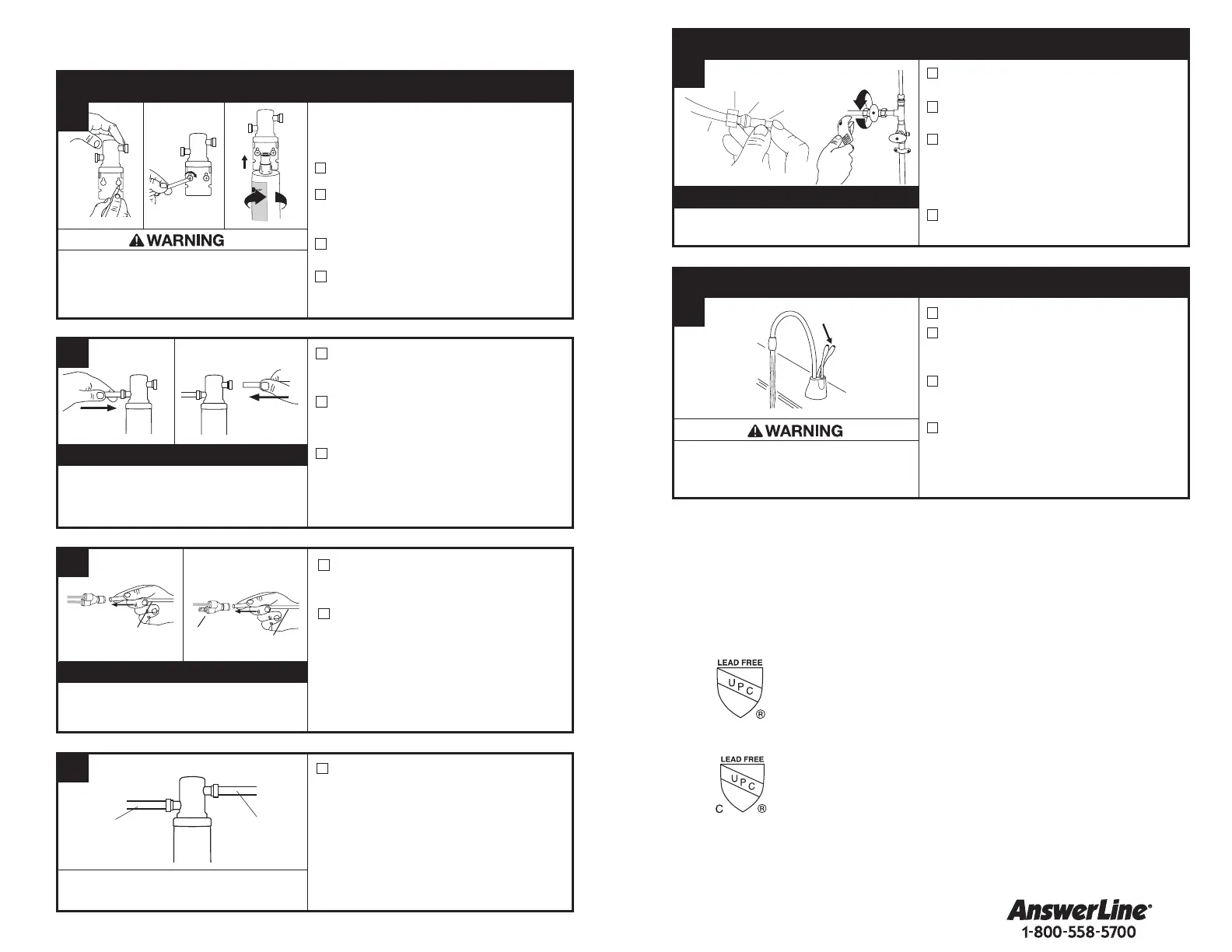

Scalding Hazard: The faucet dispenses near-boiling

(212ºF) water which can instantly cause scalds or burns.

Use care when operating this appliance.

Property Damage: Join remaining tube

to cold water supply only.

Turn on the water supply.

Depress the dispenser’s HOT handle

and hold it until water flows from the

spout (approximately 1 to 2 minutes).

Flush 3 gallons (11.4 L) through filter

before first use (approximately 4

minutes).

Check all connections to ensure they

are tight and that there are no leaks.

Install a T-fitting (not included)

onto the cold water supply line.

Install dedicated water control valve

with 1/4" compression fitting.

At the end of the 1/4" tube

from the filter or quick-connector,

slide the supplied brass nut and

ferrule over the tube and then push

in the brass tube insert.

Insert the 1/4" tube into the 1/4"

compression fitting and tighten.

FINAL WATER CONNECTION

TURN ON WATER & CONNECT POWER

Brass Nut

Ferrule

Brass

Insert

1/4"

Plastic

Tube

3

2

1

5

4

a

a

From filter or

water supply line

Plug

From filter or

water supply line

All Hot/Cold models

excluding HC3300

Cold-only models and Hot-only

models, including HC3300

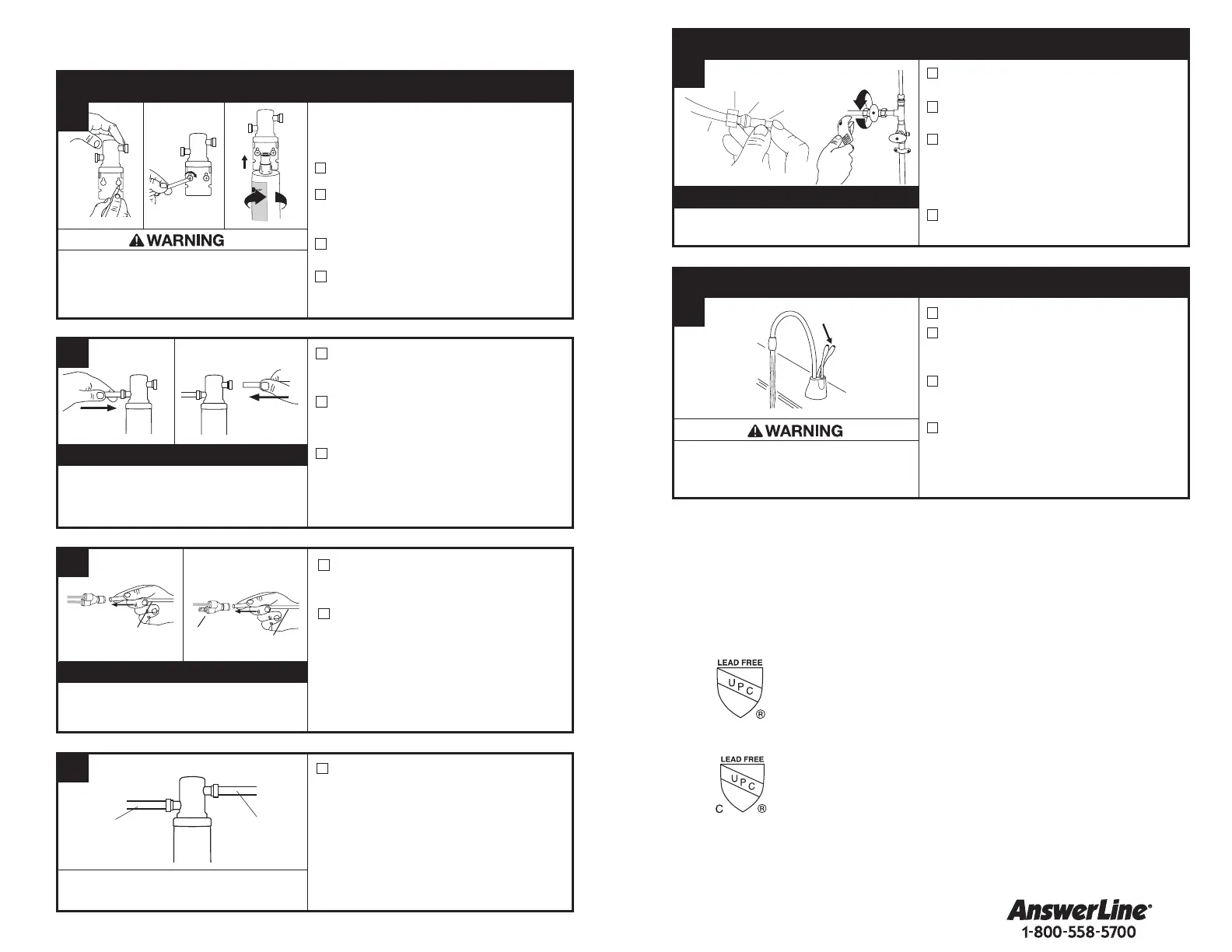

Determine length of tubing required,

then cut to length making sure the cut

is perpendicular and burr-free.

Insert a 1/4" tube into inlet side of filter

head until it stops. Press in again to

ensure a secure fit.

Insert the other 1/4" tube into outlet

side of filter head until it stops. Press

in again to ensure a secure fit.

Separate cartridge from filter head.

Mark hole locations for filter head

and bracket in a spot that allows

for filter replacement.

Drill 1/8" starter holes and attach bracket

to wall with wood screws, turning until snug.

Insert cartridge into filter head. Top

surface of cartridge will become flush with

bottom of filter head when fully engaged.

Connect remaining 1/4" tube to

incoming water supply line.

Insert the copper tubes(s) from the

dispenser into “Y” quick-connector

using the plug for hot-only models.

Connect the 1/4" tube from the right

outlet on the filter head into the quick-

connect fitting until it stops. Press in

again to ensure a secure fit.

To remove tube(s) or plug from quick-connector,

depress the release ring and gently pull away.

Screws provided are for use in wood

studs or cabinets only. Use wall anchors

(not supplied) for installation into drywall.

NOTICE

Refer to the Performance Data Sheet online for InSinkErator

Filter System Models F-1000S Plus or F-2000S Plus. Contact an

authorized InSinkErator service agent for repairs or replacement

components. Replacement filters F-1000 Plus and F-2000 Plus can

be ordered by calling 800-558-5700, visiting shop.insinkerator.com,

or by contacting an authorized InSinkErator reseller.

Pressure: 30-80 psi (207-550 kPA)

Temperature: 33˚F - 100˚F

F-1000S Plus Flowrate: 1.0 gpm

F-2000S Plus Flowrate: 0.75 gpm

Capacity: 500 gallons

The F-1000 PLUS is certified by IAPMO R&T against NSF/ANSI Standard

42 for the reduction of claims specified on the performance data sheet

when used in system HWT200-F1000S PLUS. HWT200-F1000S PLUS

is also certified against NSF/ANSI 58 for material safety requirement and

NSF/ANSI 372 for Lead Free and CSA B483.1.

The F-2000 PLUS filter is certified by IAPMO R&T against NSF/

ANSI standards 42, 53, 401 and CSA B483.1 for the reduction of the

substances listed on the performance data sheet when used in system

HWT300-F2000S PLUS. HWT300-F2000S PLUS is also certified

against NSF/ANSI 58 for material safety requirement and NSF/ANSI 372

for Lead Free and CSA B483.1.

Loading...

Loading...