Fastlane

®

Swim Unit Installation Fastlane

®

Swim Unit Installation

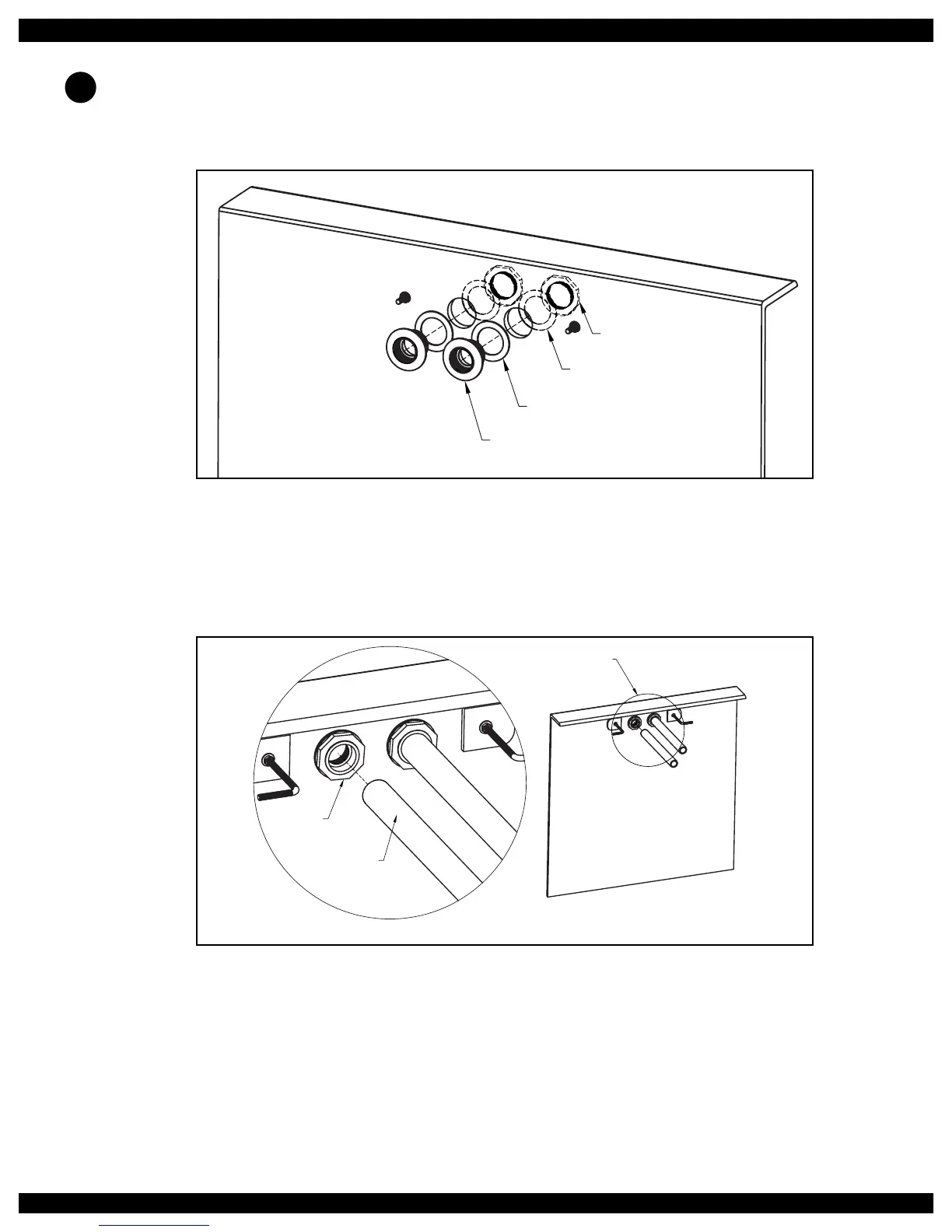

The backside of the thru-wall holes may need to be sanded at so that a proper seal can be made. Place one

of the rubber gaskets onto each thru-wall tting. The second rubber gasket will not be used in this applica-

tion. Insert the thru-wall ttings into the cut outs and place the cork gaskets onto the ttings on the backside

of the pool wall. Thread the lock nuts onto the ttings. The lock nuts should be tightened with a pair of

channel locks or strap wrench (Fig 4.27).

Thru-W

all

Fi

tting

Rubber

Ga

sket

Lo

ck Nu

t

Cork

Ga

sket

Fig. 4.27

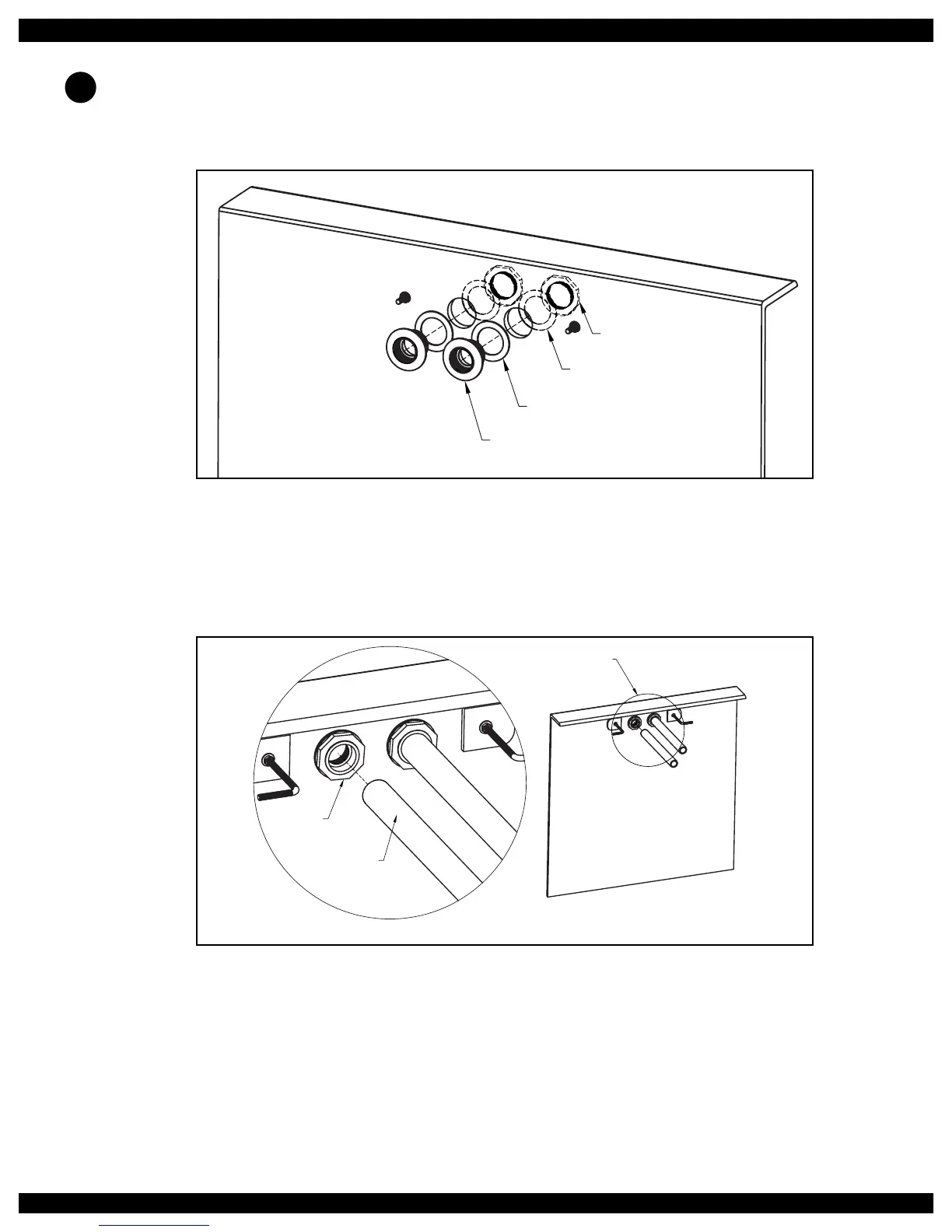

Unroll the exible PVC from the wall mount bracket back to the hydraulic power unit. Any bends in the

exible PVC should be gradual sweeps and not sharp to allow the hydraulic hoses to easily be fed through

each conduit. Each length of PVC must be no longer than 21ft (6,4m) and should exit the ground near the

hydraulic power unit. Glue the PVC ex pipe into the thru-wall ttings at the wall mount bracket (Fig

4.28).

DETAIL A

PVC Flex Pipe

(See Detail A)

Thru-Wall

Fitting

1-1/2" (38mm)

PVC Flex Pipe

Fig. 4.28

If the distance between the wall mount bracket and the hydraulic power unit is greater than 25ft (7,6m)

then a junction box and additional ex pipe must be employed. In this case, the ex pipe between the wall

mount bracket and the junction box must be 24ft 6in (7,5m). This will allow the hydraulic hoses attached to

the Fastlane to terminate just inside the junction box. See section 5 for additional information.

22

W

Loading...

Loading...