A CU MANUAL

IOM-14 25 of 46 Feb 06 R4

10. Pressurize the system to a slight positive pressure, (one or two psig). Replace all Schraeder valve

cores. Do not allow air into the system.

11. Reinstall gauges, proceed to the start-up section for charging instructions.

NEVER use system compressors to evacuate a system. Operating a compressor while the

system is under a high vacuum may cause internal arcing of the windings and

compressor failure. Compressor damage caused by high vacuum operation is not

covered by system warranty.

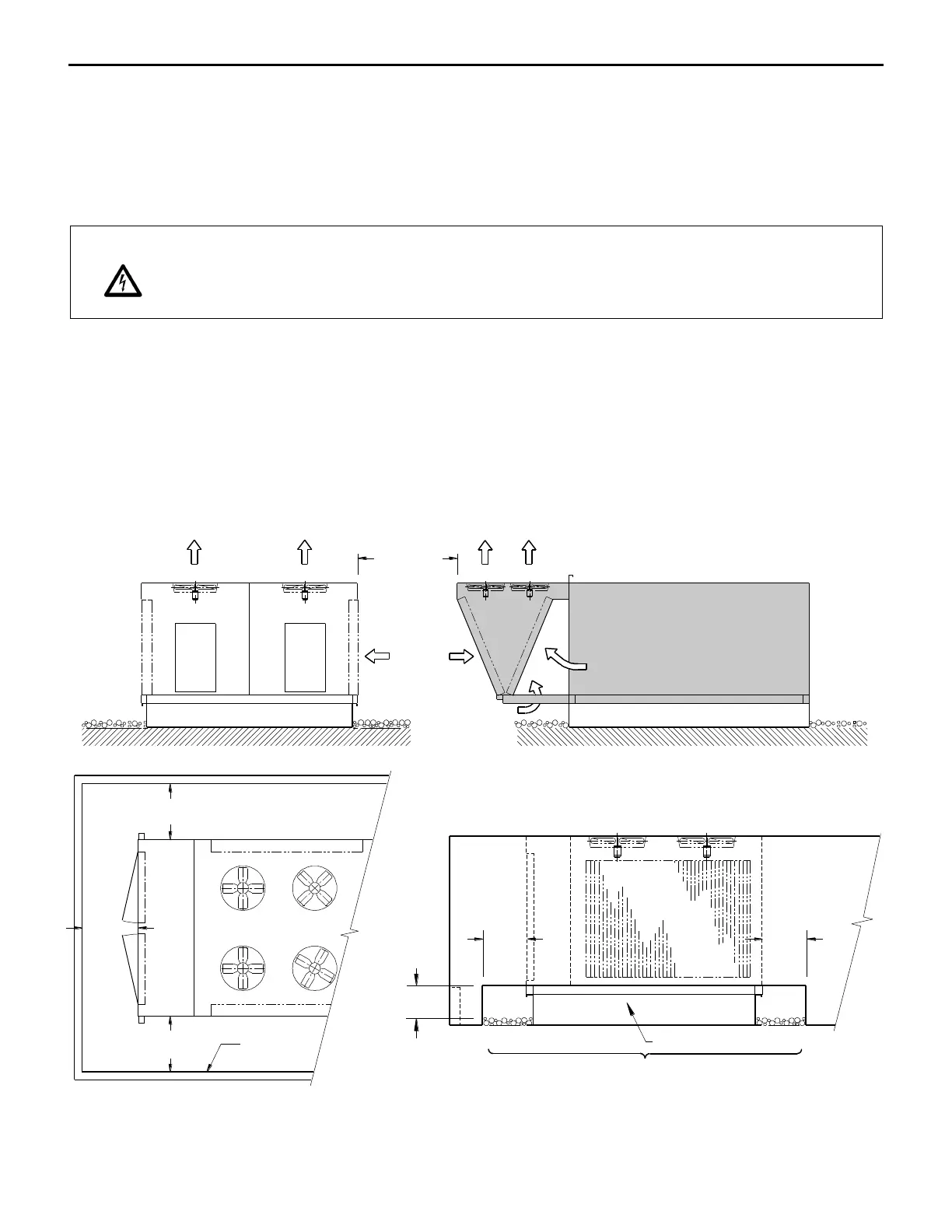

CLEARANCE FOR CONDENSER AIR FLOW

Proper air flow is essential for the operation of this equipment. Maintain at least 60” (1500 mm) clearance

between the condenser coil and any obstruction. Maintain at least 96” (2400mm) between adjacent

condensing sections. Do not place condenser sections in a well. Wells create a situation where air re-

circulates from the condenser fan back to the condenser coil. Enclosures must be designed for proper air

flow and to prevent blockage or re-circulated air.

CONDENSER COIL

CONDENSER SECTION

COMPRESSOR SECTION

2438mm

96" (MIN)

1524

60" (MIN)

1524

60" (MIN)

36" (MIN)

914

C

O

N

D

E

N

S

E

R

C

O

I

L

ENCLOSURE OR

OBSTRUCTION

CURB OR SUPPORTCURB OR SUPPORT

ELEVATION VIEW

ELEVATION VIEW

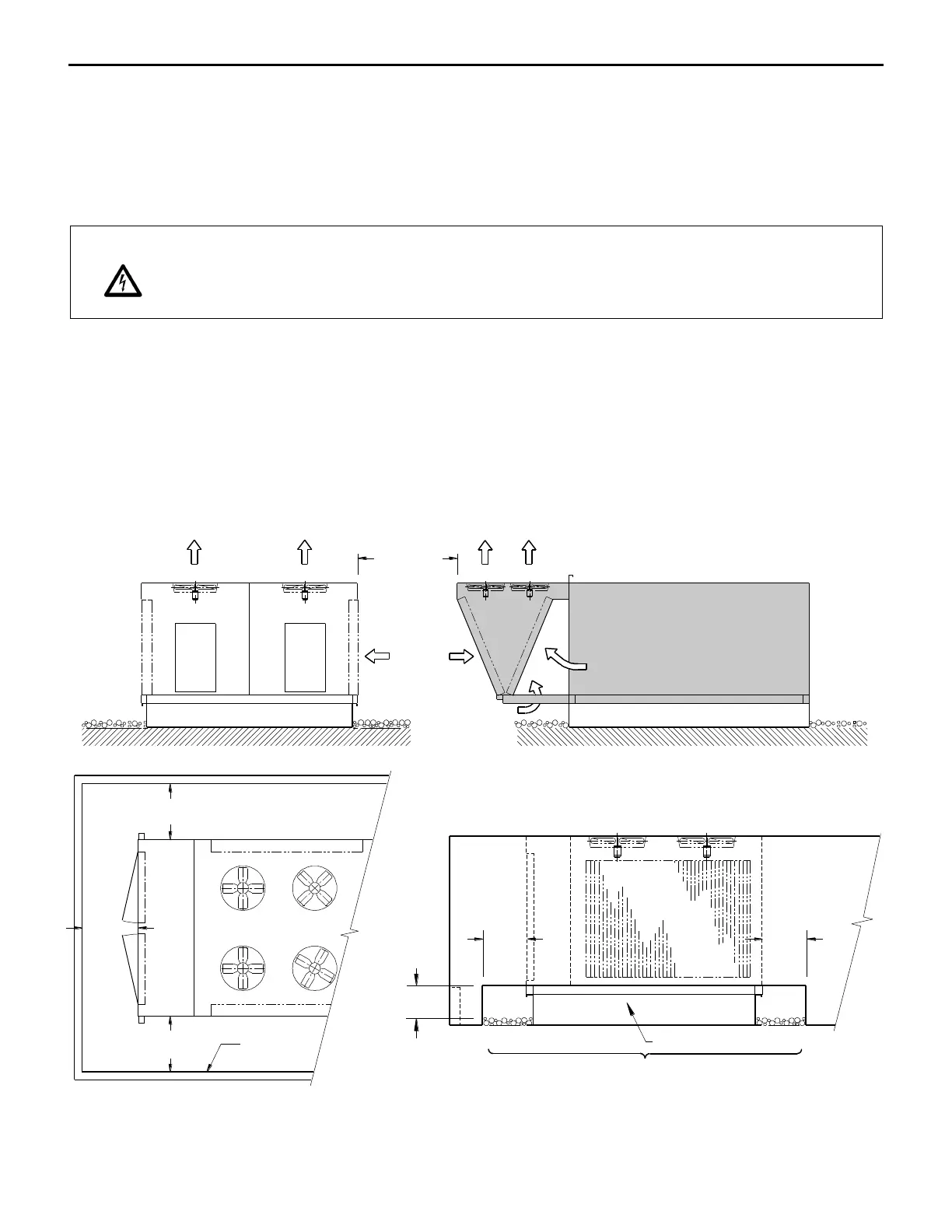

PLAN VIEW

CONDENSER COIL

CURB OR SUPPORT

610mm

24" (MIN)

12" (MIN)

305mm

DO NOT OBSTRUCT

CONDENSIGN UNIT

1219mm

48" (MIN)

CONDENSER COIL

CONDENSER COIL

C

O

N

D

E

N

S

E

R

C

O

I

L

Loading...

Loading...