Entec West, Inc.

16710 SW 72nd • Portland, Oregon 97224 • (503) 624-7118

3

System Descriptions EW-4200D

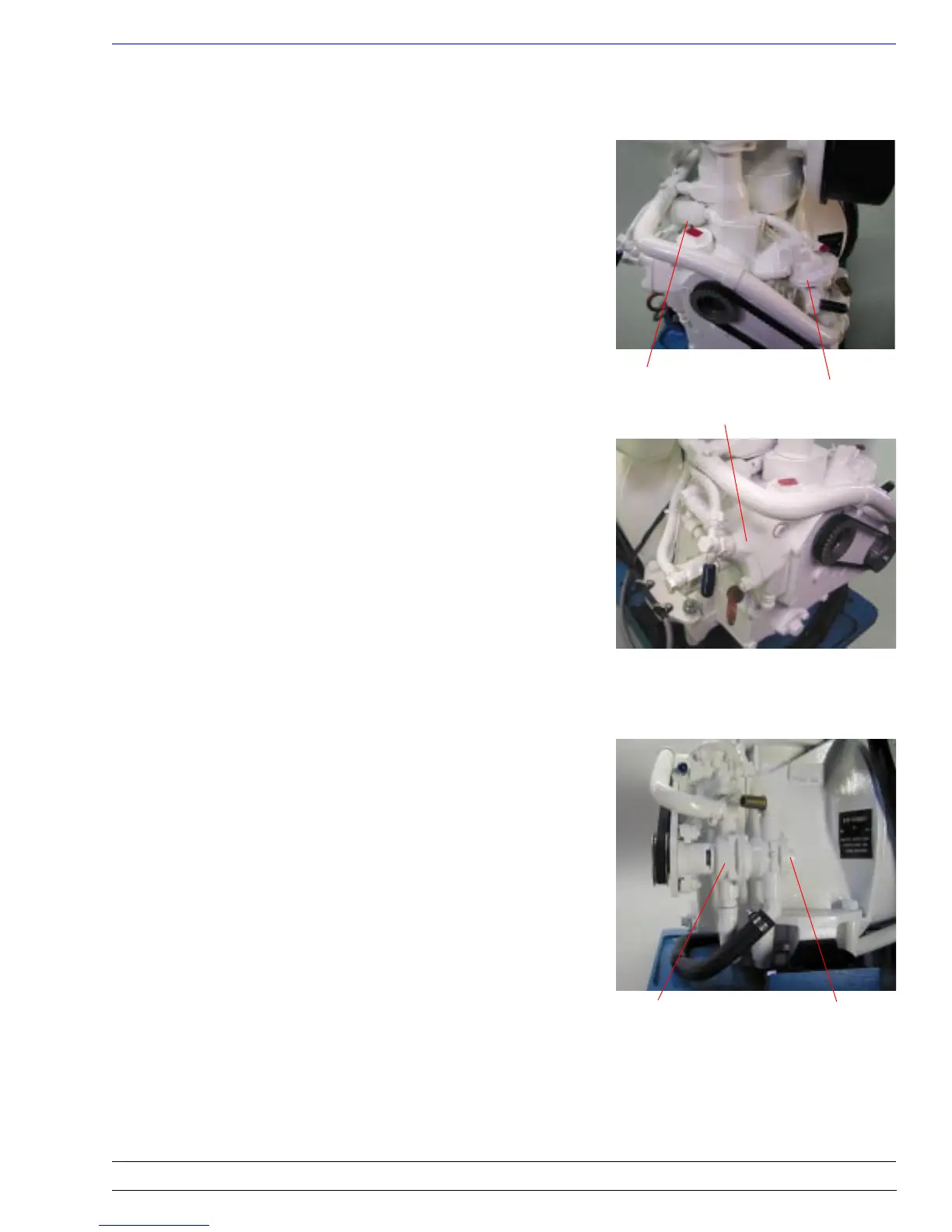

FUEL SYSTEM

In a normal installation, fuel is drawn out of the fuel tank

through the primary “water/separator fuel filter” by the engine

driven, diaphram type, Fuel Pump (3/50). From the Fuel Pump it

goes first through the engine Fuel Filter (11/10), then to the Fuel

Injection Pump (3/29).

It is important to know that most of the fuel delivered to the Fuel

Injection Pump by the Fuel Pump, is surplus, and is returned to

the fuel tank. The Fuel Pump is pumping at a rate of approxi-

mately 3.17 gallons per hour. The Fuel Injection Pump will only

use 0.4 of a gallon per hour (when the generator is producing 30

amps of electrical power). The high volume of return flow

provides a continuous cleaning action of the fuel through the

vessel’s filter. This will help to keep the fuel in the tank clean.

Fuel Filter

Fuel Pump

Fuel Injection Pump

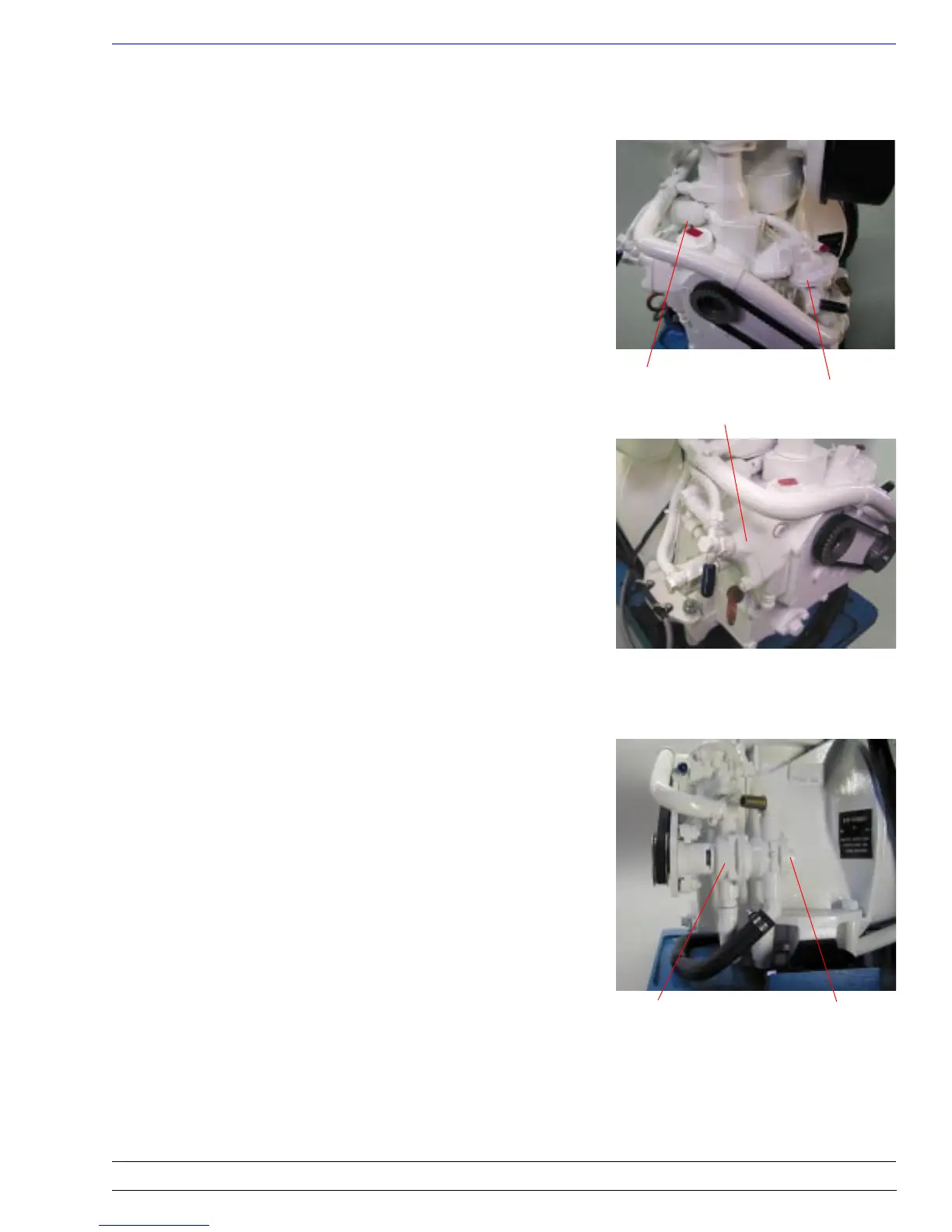

WATER PUMPS

The Water Pumps are flexible impeller types. Each pump is

complete and independent of the other, except the Raw Water

Pump is “piggybacked” onto the Fresh Water Pump. The shaft

tang of the Raw Water Pump extends beyond the pump housing

and fits into the pump shaft slot of the Fresh Water Pump (21/0).

Fresh Water

Pump

Raw Water

Pump

Loading...

Loading...