© EnvisionTEC Page 2 of 4

TS-OPI-PCA-4000-V20210311-FN-EN.pdf

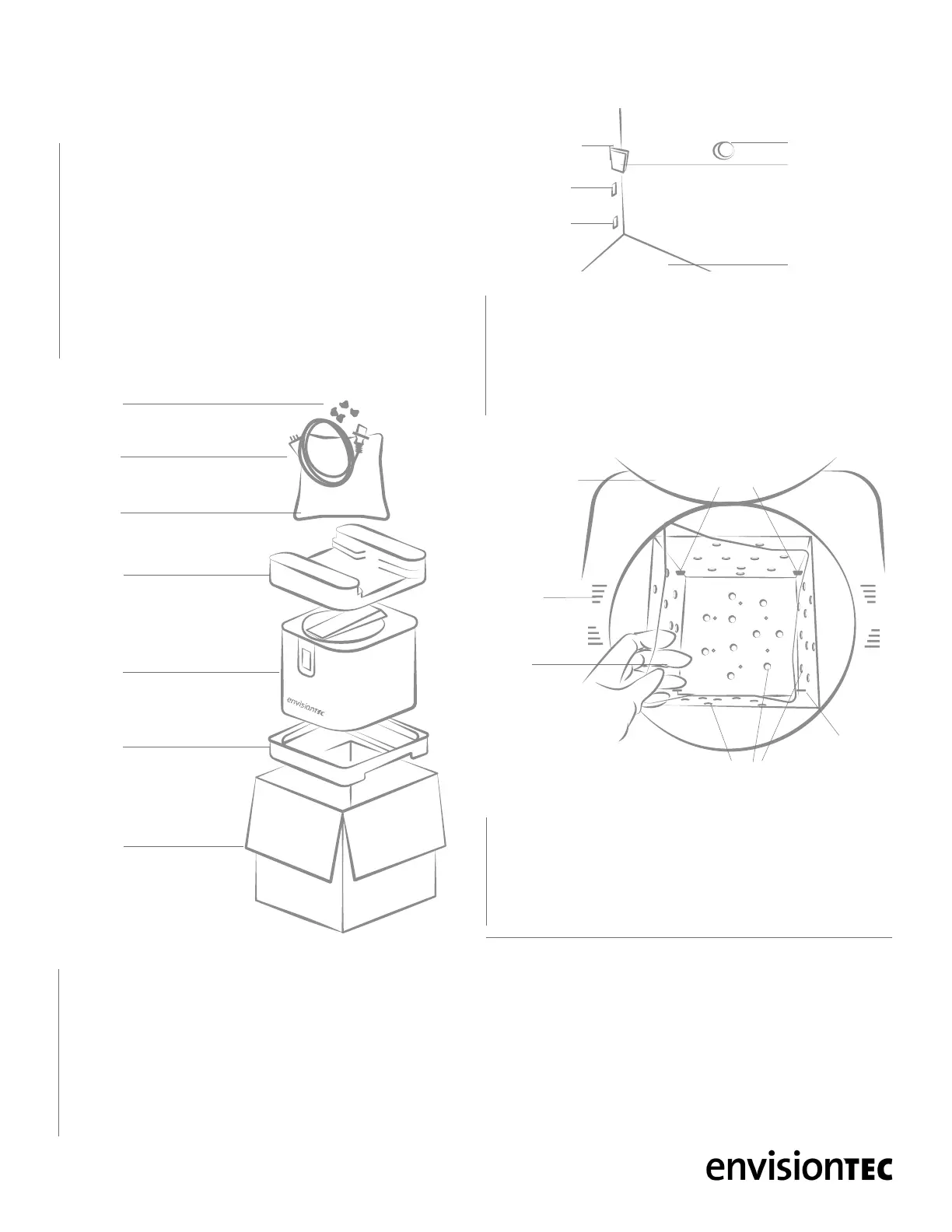

10 Once all four tray supports are in place, the post curing tray

can be lowered into the curing chamber, Fig. 5. Close the curing

compartment lid

11 Connect the power cable to the PCA 4000 and into a power

socket US - 110V / EU - 220V with a grounding socket. A controlled

switch socket is prefered as this would allow the operator to easily

disconnect the power to the apparatus when not in use - see Safety

Instructions

Powering on the PCA 4000

12 Once power cable is connected, the PCA 4000 can be powered

on via the power switch at the back of the unit.

The PCA 4000 will display a brief start-up screen and will then go

to stand-by mode. In this mode the PCA 4000 is ready to start the

required program. It is connected to power, but does not emit UV

rays while in stand-by mode - see Safety Instructions p. 4

Programs and Features

Main menu

Once the PCA 4000 is powered on, it automatically switches to the

Main menu. While in the Main menu, the curing oven is powered on

and ready to start the program selected by the user, but the LED lights

are not ignited.

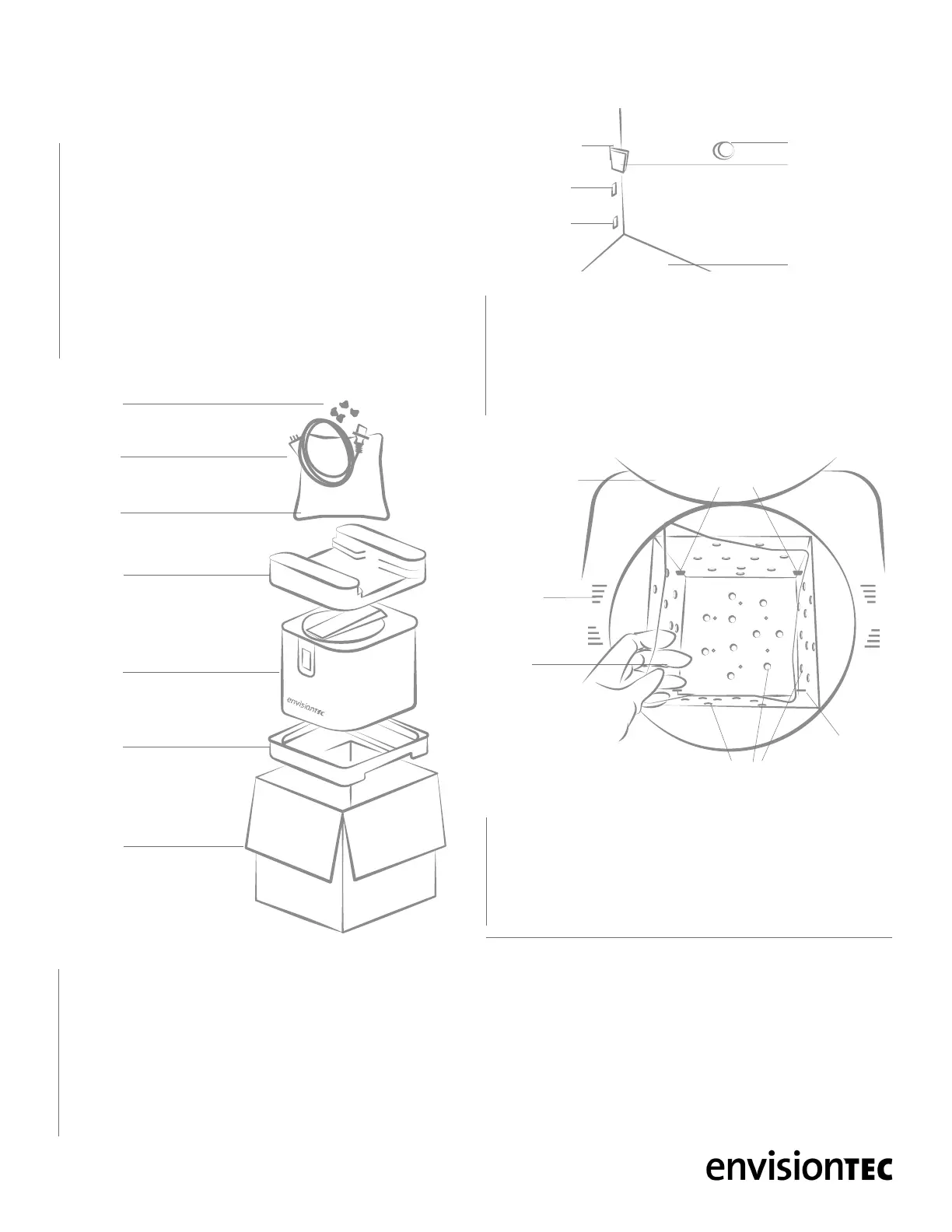

Product Assembly

Unpacking the PCA 4000

1 Carefully open the packaging: Do not use blades that could

damage the contents

2 Accessories for the PCA 4000 are packed on the top foam panel

- power cable, post curing tray, and tray supports to hold the post

curing tray in place, Fig. 3. Remove these from the box and set

aside

3 Extract the PCA 4000 from the box by lifting upwards

4 Remove the foam panels from the top and bottom

5 Do not throw away the box and foam panels. Keep the packaging

6 Situate the PCA 4000 on a secure surface. Place the PCA

4000 at a distance of at least 8 inches (20 cm) from any other

object, including the back wall. This is essential in order to avoid

obstructing the ducts of the PCA 4000’s cooling system - see

Safety Instructions p. 4

Installing the accessories

7 The post curing tray, Fig. 3, has a protective lm that will need to

be removed from both sides before installation. Always handle the

tray with gloved hands to avoid leaving nger prints

8 Locate the bag with the four small plastic tray supports, Fig. 3.

Remove these from their bag

9 In each corner inside the curing chamber there is a top hole,

middle hole, and bottom hole, Fig. 4. It is recommended to place

the tray supports in the top holes to ensure the models are an even

distance from all lights during the curing process. Open the curing

compartment lid, Fig. 1, and install the four tray supports in the four

top holes

00:00

Connected

Set

Program

CLEAR

BASIC

CUSTOM

CUSTOM

BASIC

CLEAR

START

Set Timer

00:02:00

START

Set Temp

20

°C

START

Set Power

100%

Program 0

Power

Temp

Time

START

100%

20

°

C

00:02:00

Set PRG

Prog: 0

Prog: 0

Prog: 1

Prog: 2

Prog: 3

Prog: 4

Prog: 5

Prog: 5

100%

100%

100%

100%

100%

100%

100%

30°C

30°C

30°C

30°C

30°C

30°C

30°C

00:10:00

00:10:00

00:10:00

00:10:00

00:10:00

00:10:00

00:10:00

Set PRG

PCA

4000

Foam

panel

Foam

panel

Box

Post

curing

tray

Power

cable

Tray

supports

PCA 4000 UNPACKINGFig. 3

PCA 4000 TRAY SUPPORTS POSITIONFig. 4

00:00

Connected

Set

Program

CLEAR

BASIC

CUSTOM

CUSTOM

BASIC

CLEAR

START

Set Timer

00:02:00

START

Set Temp

20

°C

START

Set Power

100%

Program 0

Power

Temp

Time

START

100%

20

°

C

00:02:00

Set PRG

Prog: 0

Prog: 0

Prog: 1

Prog: 2

Prog: 3

Prog: 4

Prog: 5

Prog: 5

100%

100%

100%

100%

100%

100%

100%

30°C

30°C

30°C

30°C

30°C

30°C

30°C

00:10:00

00:10:00

00:10:00

00:10:00

00:10:00

00:10:00

00:10:00

Set PRG

LED bulb

Tray

support

Base of curing

chamber

Top hole

Middle hole

Bottom hole

PCA 4000 INSTALLING POST CURING TRAYFig. 5

Time

00:01:00

Temp

20

°C

Time

START

00:01:00

Program

1

Temp

Power

60%

20

°

C

Power

35%

Time

START

00:01:00

E-Orthoshape

Main menu

Program

1

Program

2

Program

3

Program

4

Program

5

Program

6

Program

7

Program

8

Main menu

E-Orthoshape

E-Model HS E-SepFree

E-Tray Easy Cast

E-Shell

200 Series

PCA4000

30

°

C 35

°

C 40

°

C 45

°

C

STANDARDCUSTOM

Post

curing

tray

Cooling

ducts

Tray

supports

Curing

chamber lid

LED bulbs

Curing

chamber

Loading...

Loading...