3

any doubt about the adequacy of gas flows, use an

oxygen test gauge adaptor (P/N 07X17) and either

the acetylene (P/N 262510) or fuel gas (P/N 639422)

test gauge adaptor while the torch is operating to

make sure that the recommended operating pres-

sures are available at the torch inlet.

7. Manifold two or more fuel gas cylinders to assure

adequate supply of fuel gas. The tables show the

number of commonly used cylinders recommended

for manifolding when using larger heads. If using

other cylinders or gases, check with your fuel gas

supplier for recommended withdrawal rate informa-

tion.

8. In the event of a flashback, immediately close both

oxygen and fuel gas valves on the torch (preferably

oxygen valve first). For greater protection, install

1/4-turn quick shut off valve (P/N 999306) on the

torch oxygen hose connection.

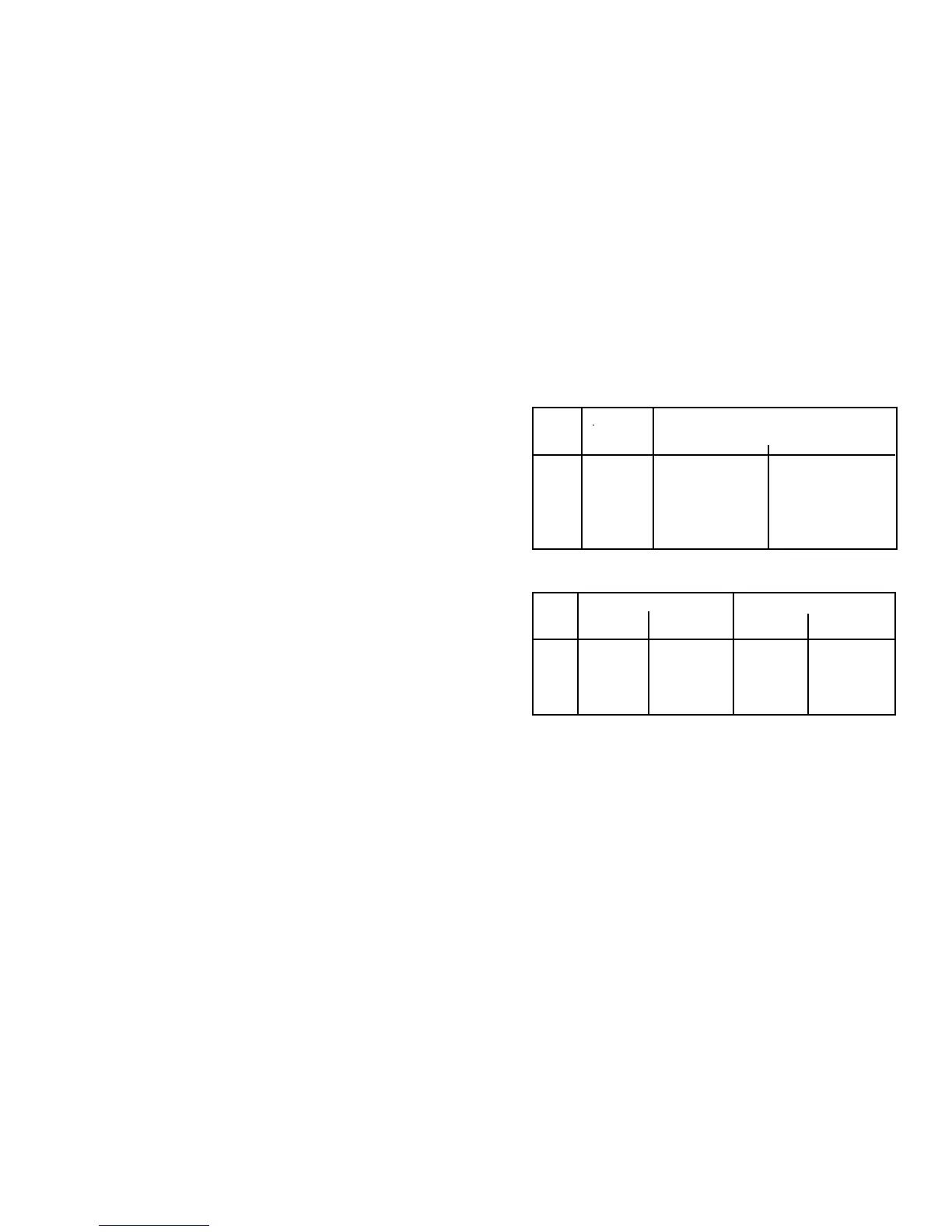

Acetylene

Head Flowrate, Min. No. of Cylinders Required*

Size cfh WK Cyl (300 cf) WTL Cyl. (390 cf)

55 55 2 1

70 70 2 2

100 100 3 2

150 150 4 3

200 200 5 4

250 250 6 5

* Based on that max. hourly flowrate should not exceed 1/7 of cylinder capacity

at 70° F. Example: 1/7 (300 cf WK cyl.) = 43 cfh max.

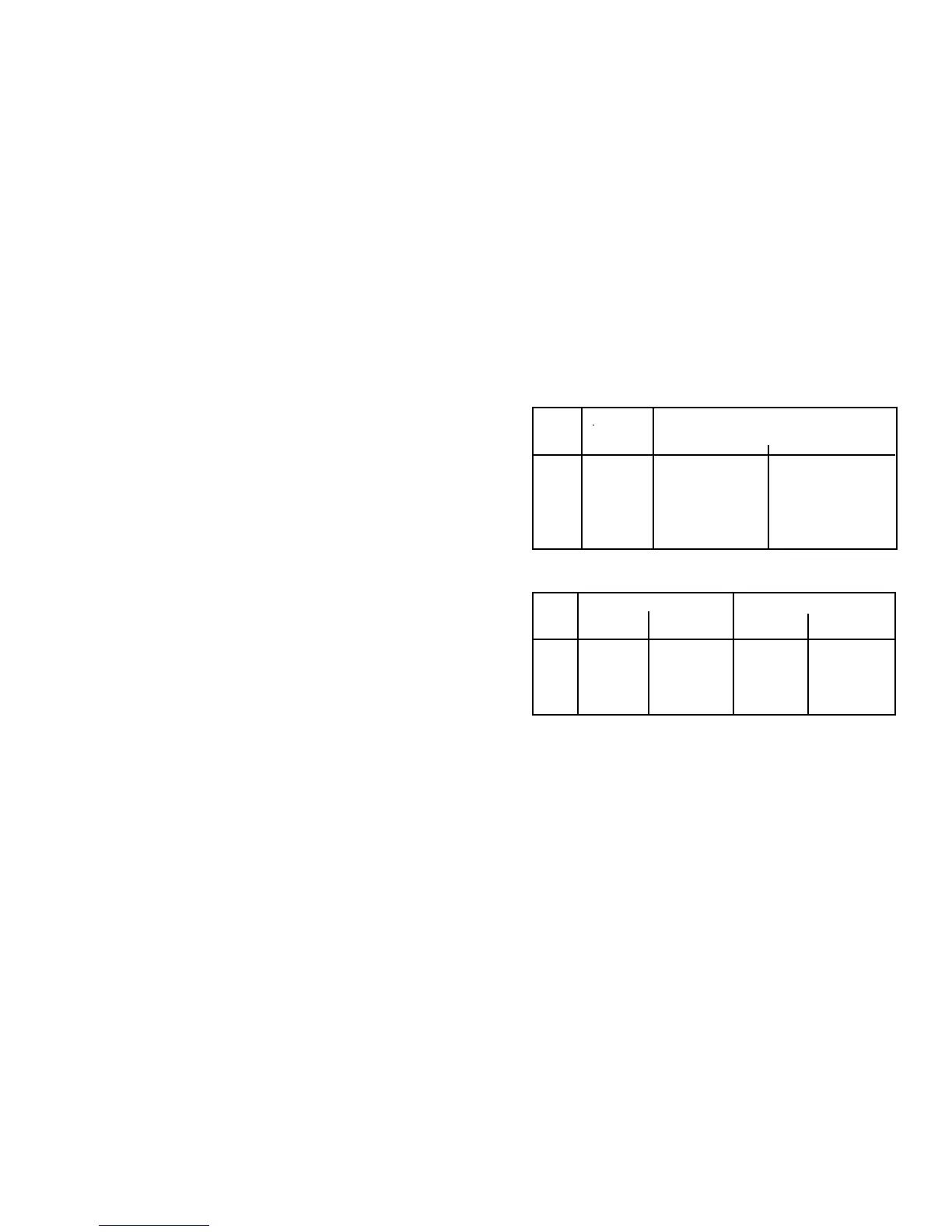

FG-2 (104 Ib. cyl.) Propane (100 Ib. cyl.)

Head Min. No. of Min. No. of

Size Flowrate Cyl Req'd* Flowrate Cyl. Req'd**

70 43 1 40 1

100 62 1 58 1

150 93 1 86 2

200 124 2 116 2

250 - - 144 3

* Based on max. continuous withdrawal rate of 110 cfh for 104 Ib. cylinder,

1/2 full @ 70° F.

** Based on max. continuous withdrawal rate of 65 cfh for 100 lb. cylinder,

1/2 full @ 70° F.

Withdrawal rate will increase with wind velocity and intermittent usage;

reduce with lower temperature.

9. If the inner cone of the flame appears too short

(less than 1/4-in.), you are lacking fuel gas and the

head will tend to overheat. Recheck the above

precaution with your set up.

10. Do not bring the head too close to the work. Maintain

a distance of at least 1/4-in. between tip and work.

RECOMMENDED HOSE SIZES

Oxygen, Acetylene (medium-pressure) and Natural

Gas (at pipeline pressure over 5 psig): With head

sizes 4-30, 1/4-in. or 3/8-in. I.D. With head sizes 55 and

larger, 3/8-in I.D.

Acetylene (low-pressure) and Natural Gas (at pipe-

line pressure below 5 psi): With head sizes 4-70, 3/

8-in. I.D. hose. Head sizes 100-250, 1/2-in. hose. Do

not use over 25 feet of hose.

SHUTTING OFF

Close the fuel gas valve first, then the oxygen valve.

If operations are to be stopped for a half-hour or more,

all pressure should be released from the torch hoses,

and regulators by doing the following:

1. Close each cylinder or station valve.

2. Open torch valves.

3. After relieving the gases, back out the pressure-

adjusting screw of each regulator and close the

torch valves.

IMPORTANT OPERATING NOTES

1. Do not attempt to operate heads size 100 or larger

from a low-pressure acetylene supply (less than 5

psig).

2. Head size number of each welding and heating

head indicates the rated acetylene capacity in

cubic feet/hour (cfh). For example, No. 55A re-

quires about 55 cfh of acetylene at normal operat-

ing pressure. However, on heating heads designed

for other fuel gases, the size indicates the approxi-

mate equivalent heating capacity in terms of acety-

lene flow. For example, No. 100A and No. 100FG

provide the same average heating output (147,000

Btu/hr) but No. 100FG head really requires about

62 cfh of FG-2, 57 cfh of propane, or 147 cfh of

natural gas.

For consumption purposes, the following are the oxy-

gen/fuel gas ratios normally required for welding and

heating:

1.1 to 1.5 cfh oxygen/1.0 cfh acetylene

3.2 to 3.6 cfh oxygen/1.0 cfh FG-2

3.5 to 4.5 cfh oxygen/1.0 cfh propane

1.7 to 2.0 cfh oxygen/1.0 cfh natural gas.

PRECAUTIONS - NO. 55 and LARGER HEADS

Large welding and heating heads (No. 55 and above)

require high flow of oxygen and fuel gas for proper

operation. Failure to follow the following precau-

tions can result in serious overheating, flashback,

and possible operator injury.

1. Read and understand the operating instructions

packed with your torch as well as these precautions

before lighting up the welding or heating head.

2. Always operate with oxygen and fuel gas pressures

given in the tables.

3. Do NOT use hose line reverse flow check valves

when using No. 100 or larger welding or heating

head.

4. Use 3/8-in. I.D. hoses when using No. 55 or larger

welding or heating head.

5. Do NOT use whip hose, hose splices, nor hose

nipples smaller than 1/4-in. I.D. (“B”-size).

6. If using hose lengths greater than 25-ft., or if there is

Loading...

Loading...