Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * FAX (708)331-8919

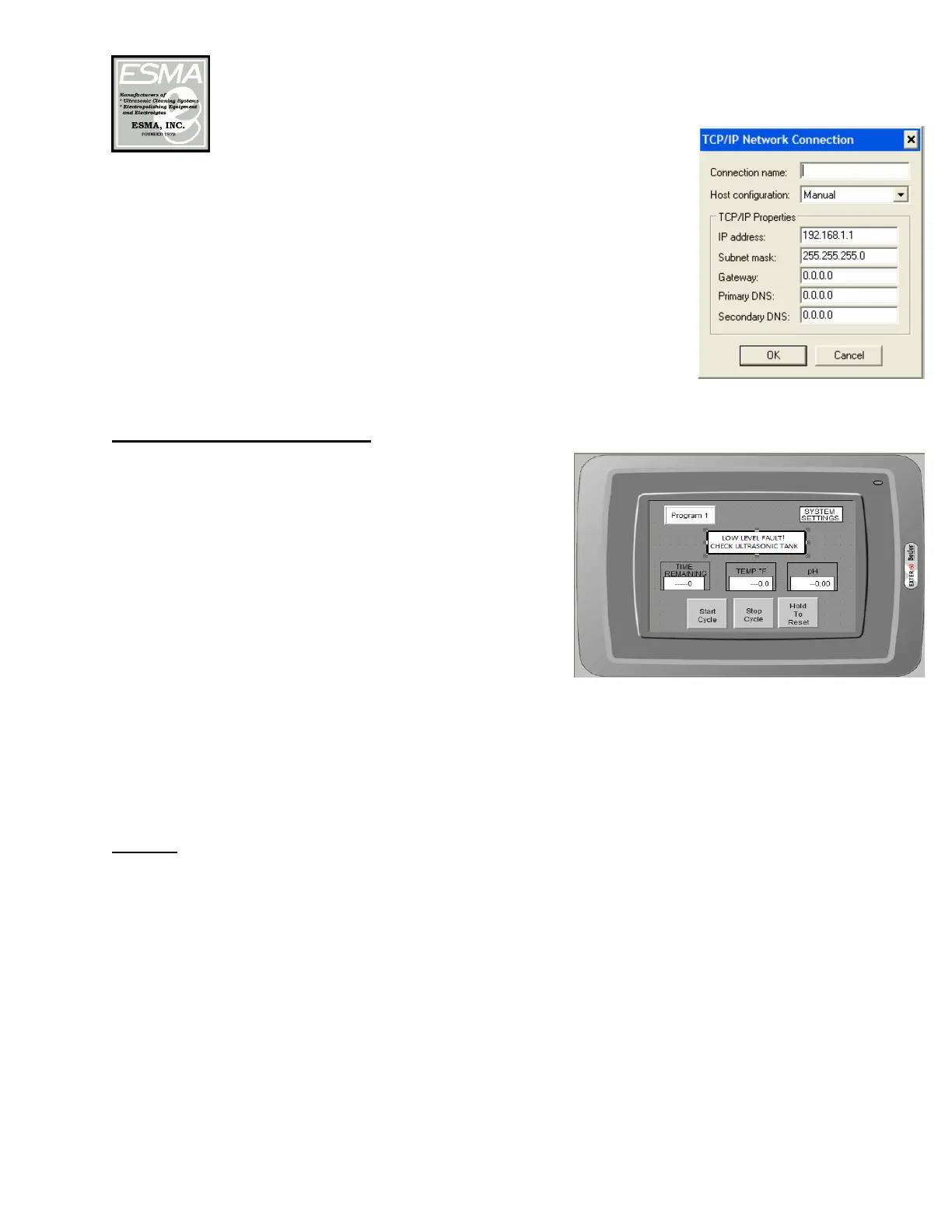

The control box on the rear of the E992 unit has an Ethernet port

for connection to a data collection server (See photo above). An

FTP protocol will need to be used to collect the data.

IP address: 192.168.1.1, Subnet mask: 255.255.255.0

The raw data is comma delimited.

High and low Level Control

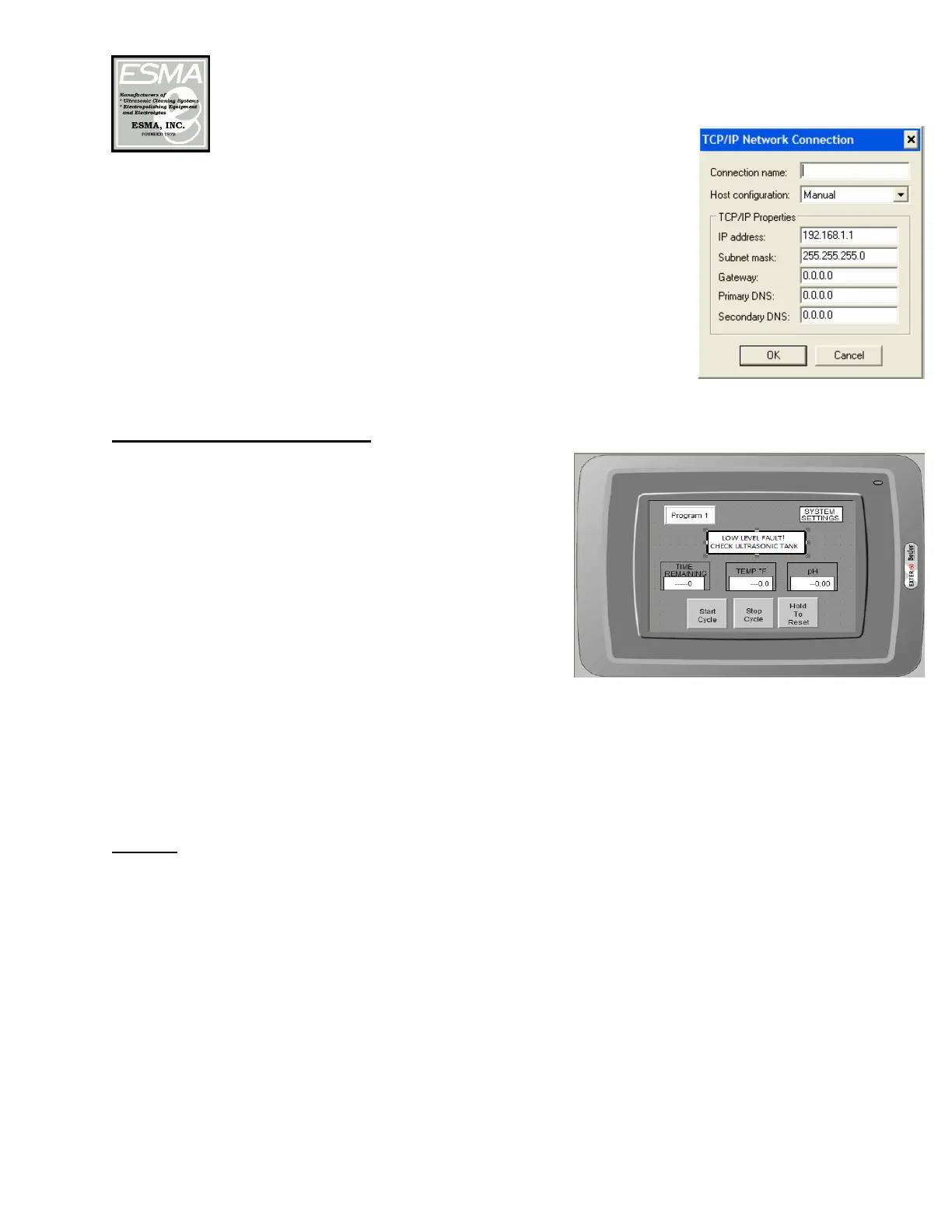

The tank has a high level sensor and a low level

sensor located in the tank wall. The high level

control will shut the main input solenoid S20 if the

solution level gets to high in the tank.

A low level sensor in the tank wall is located

approximately 3” from the bottom of the tank.

This sensor will send a signal to the PLC to halt

the program if tripped. The adjacent message will

appear on the interface in the event that this sensor

is tripped, indicating that not enough fluid was pumped into the tank:

Drying

In the drying portion of the programs, the incoming air is heated in the tank cover

to 160-180° F and forced by the fan through the tank cover. CAUTION: Do not

touch the cover during the drying cycle because some areas of the cover will be

hot.

Drying time will vary depending on the number of parts to be dried, if hot or cold

water was used to rinse parts before drying and if the cover is closed. Generally

parts should be dry in 7- 10 minutes.

Loading...

Loading...