Stopping Engine

To stop the engine in an emergency, simply turn the engine switch to the OFF position.

Under normal conditions, use the following procedure.

1. Move the throttle lever to the slow position.

2. Let engine idle for one or two minutes.

3. Turn the engine switch to the OFF position.

4. Turn the fuel valve lever to the closed position.

Note! Do not move choke control to closed position to stop engine. Backfire or

engine damage may occur.

Idle Speed

Set throttle control lever to slow position to reduce stress on the engine when compacting is

not being performed. Lowering the engine speed to idle the engine will help extend the life

of the engine, as well as conserve fuel and reduce the noise level of the machine.

LIFTING AND TRANSPORT

See technical data for the weight of the machine.

To avoid burns or fire hazards, let engine cool

before lifting or transporting machine or storing

indoors.

The unit must be transported in the upright

position to prevent fuel from spilling. Do not lay

machine on its side or top.

Secure or tie down unit using the lifting handle to

prevent machine from sliding or tipping over.

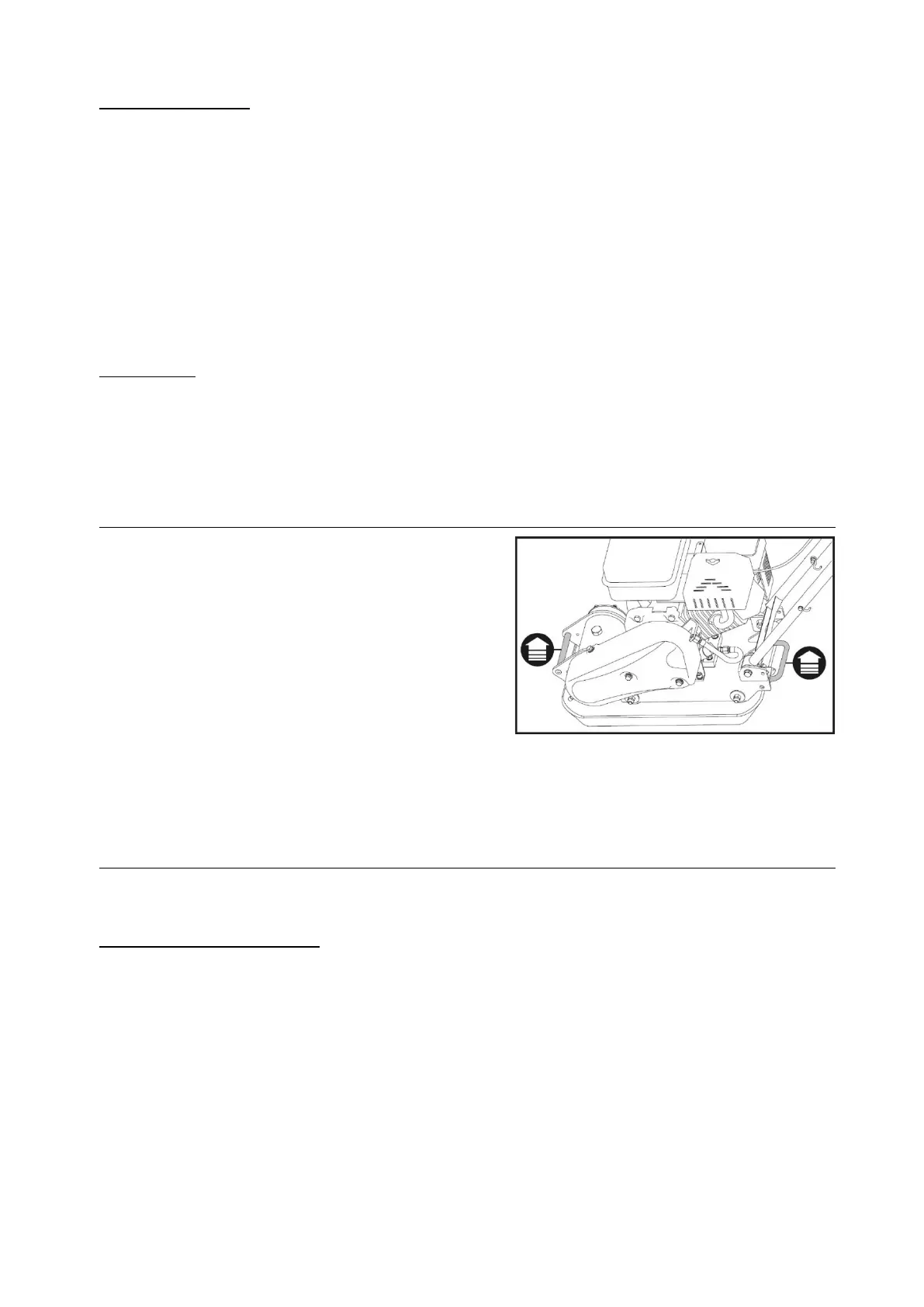

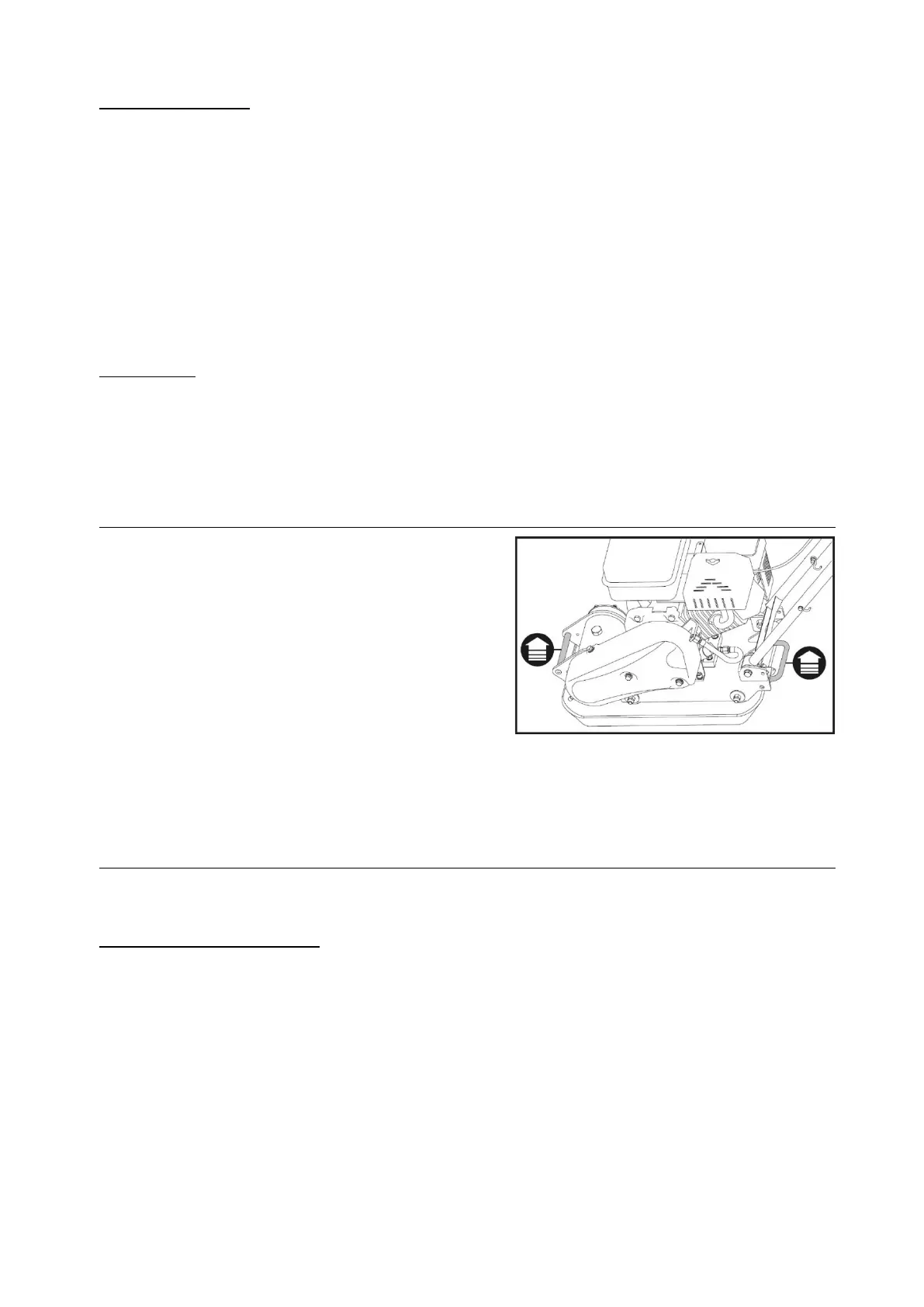

The machine may fall and cause damage or injury if lifted incorrectly. Lift using

handles at base of plate.

MAINTENANCE

Maintaining your compactor will insure long life to the machine and its components.

Preventive Maintenance

1. Turn off engine. Engine must be cool.

2. Keep the engine’s throttle lever in its slow position, and remove spark plug wire from spark

plug and secure.

3. Inspect the general condition of the plate compactor. Check for loose screws,

misalignment or binding of moving parts, cracked or broken parts, and any other

condition that may affect its safe operation.

4. Remove all debris from the plate compactor with a soft brush, vacuum, or compressed

air. Then use a premium quality lightweight machine oil to lubricate all moving parts.

5. Clean the bottom of the compactor base as soon as it begins to pick up soil being

compacted. The unit can not do a good job if the bottom surface is not smooth and clean.

6. Replace spark plug wire.

Loading...

Loading...