Version 1.03 - 3 -

3. Speed Sensor Installation

There are 2 small, powerful magnets supplied with kit. You must use both magnets for the

DD2 to read correctly. These magnets are mounted on a surface that rotates in relation to

vehicle speed and supply electrical pulses as they pass in front of the speed sensor to the

DigiDash

2

.

The harness with the RED 9-pin connector incorporates the speed sensor. The sensor can be

disconnected from this harness to aid ease of installation.

You must first locate a suitable position for mounting the speed sensor and magnets on your

vehicle. The speed sensor and magnets are commonly mounted in one of three locations: -

• Prop-shaft (either at the differential end or gearbox end)

• Drive-shaft Coupling ( with Sensor mounted on Gearbox)

• Front Hub (with sensor mounted on steering arm)

The recommended gap between the sensor and top surface of the magnets is 1mm and

therefore you must ensure that whatever location is used, any movement in the position of the

magnets is replicated in the movement of the sensor to maintain a constant gap.

You will need to fabricate a strong bracket to hold the sensor in place, and bolt this bracket to

a suitable mounting point.

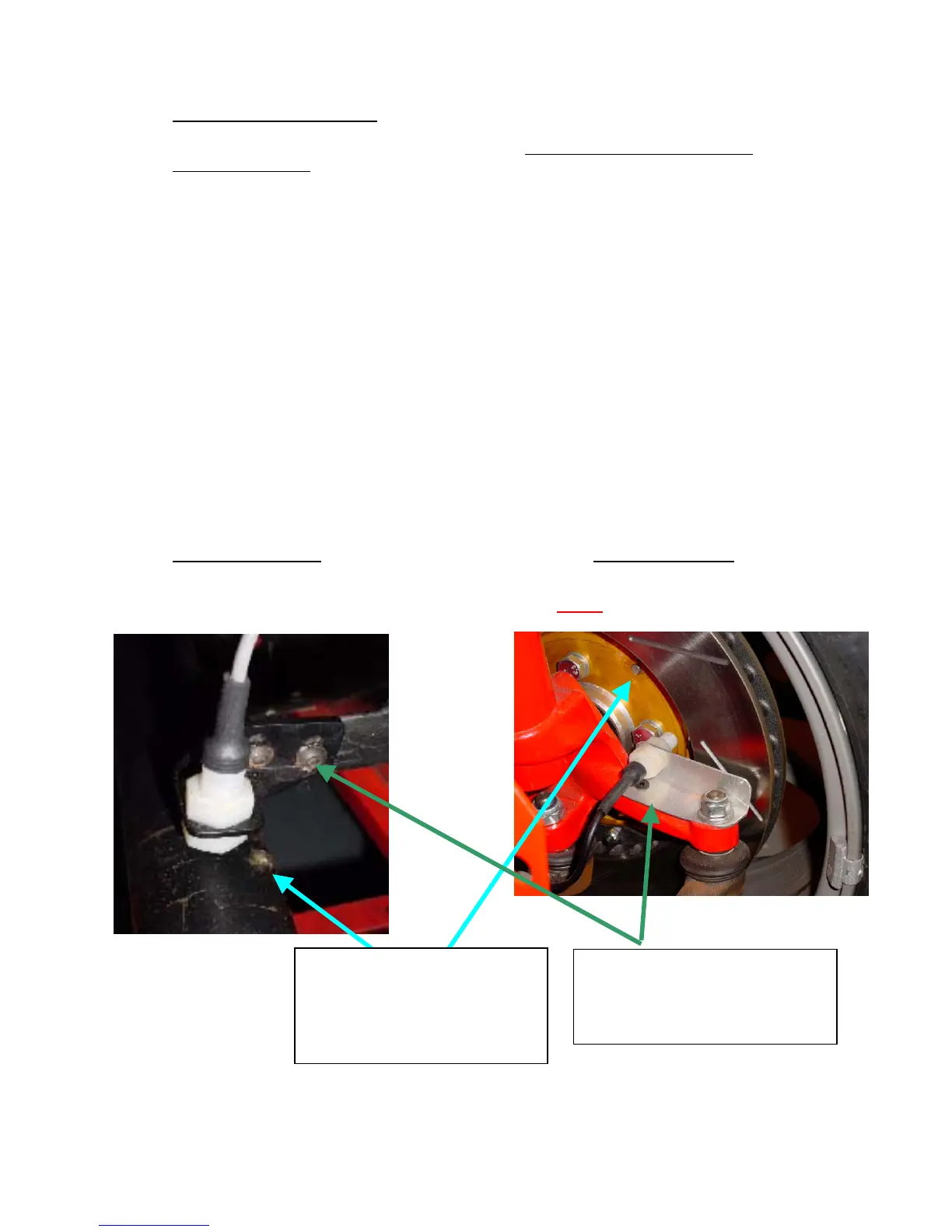

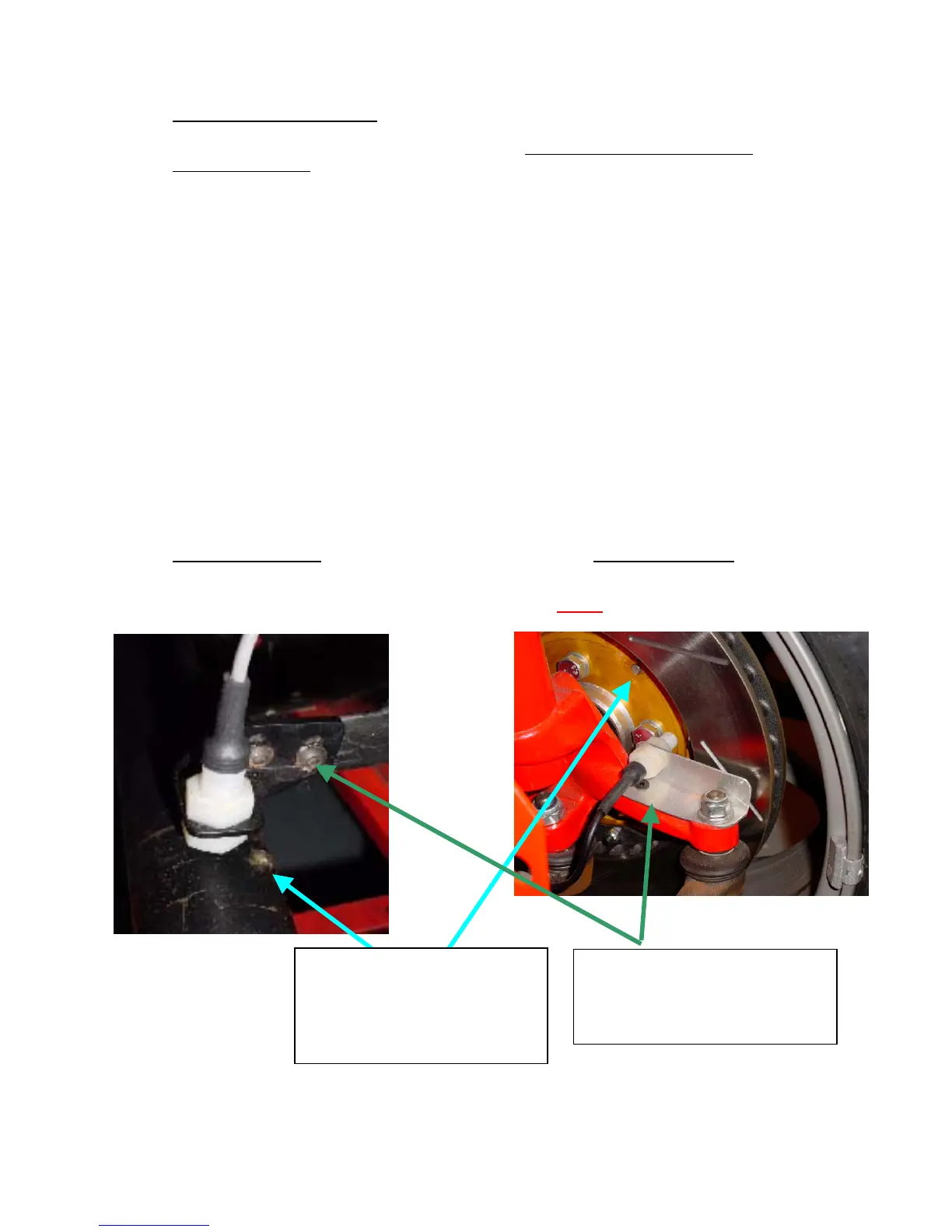

Here are 2 examples:-

Prop-Shaft Mounting Front-Hub Mounting

Important! – The speed sensor is polarity dependent. This means that the magnets

must be mounted dimple-side DOWN.

Important! - The recommended gap between the speed sensor head and top surface of

the magnets is 1mm.

Magnets glued in position.

Liberal application of a strong

adhesive such as ‘Chemical

Metal’ or ‘Araldite’ will ensure

that the magnets do not become

dislodged during use.

Strong mounting brackets that

hold the speed sensors in

position. The brackets have been

mounted in positions that move in

unison with the ma

Loading...

Loading...