13

17

ENGLISH

The outlet pipe must have:

• a diameter not less than that of the hood fitting.

• a slight slope downwards (drop) in the horizontal sections to prevent conden-

sation from flowing back into the motor.

• the minimum required number of bends.

• the minimum required length to avoid vibrations and reduce the suction per-

formance of the hood.

You are required to insulate the pipes if it passes through cold environments.

In the presence of motors with 800m3/h or higher, a check valve is present to

prevent external air flowing back.

Deviation for Germany:

when the kitchen hood is used at the same time as appliances that are powered by

energy other than electricity, the negative pressure in the room must not exceed 4 Pa

(4 x 10-5 bar).

HOOD WITH INTERNAL RECIRCULATION FILTERING

In this model, the air passes through the charcoal filters (op-

tional) to be purified and recycled in the environment.

For assembly, see the instructions.

ASSEMBLY INSTRUCTIONS

only intended for qualied personnel

The hood can be installed in various congurations.

The generic assembly steps apply to all installations; for each case,

follow the specic steps provided for the required installation.

OPERATION

WHEN TO TURN ON THE HOOD?

Switch on the hood at least one minute before starting to cook to direct fumes

and vapours towards the suction surface.

After cooking, leave the hood operating until complete extraction of all vapours

and odours. By means of the Timer function, it is possible to set auto switch-off

function which will allow the hood to turn off automatically after 15 minutes of

operation.

WHICH SPEED IS TO BE SELECTED?

speed (1-3): maintains the circulation of clean air with low electricity consump-

tion.

speed (4-5): normal conditions of use.

speed (6-7): presence of strong odours and vapours.

speed (8-P): rapid disposal of odours and vapours.

WHEN SHOULD THE FILTERS BE WASHED OR REPLACED?

The metal filters must be cleaned every 30 hours of operation.

The active carbon filters must be replaced every 3-4 months, depending on the

use of the hood.

For further details see the “MAINTENANCE” chap.

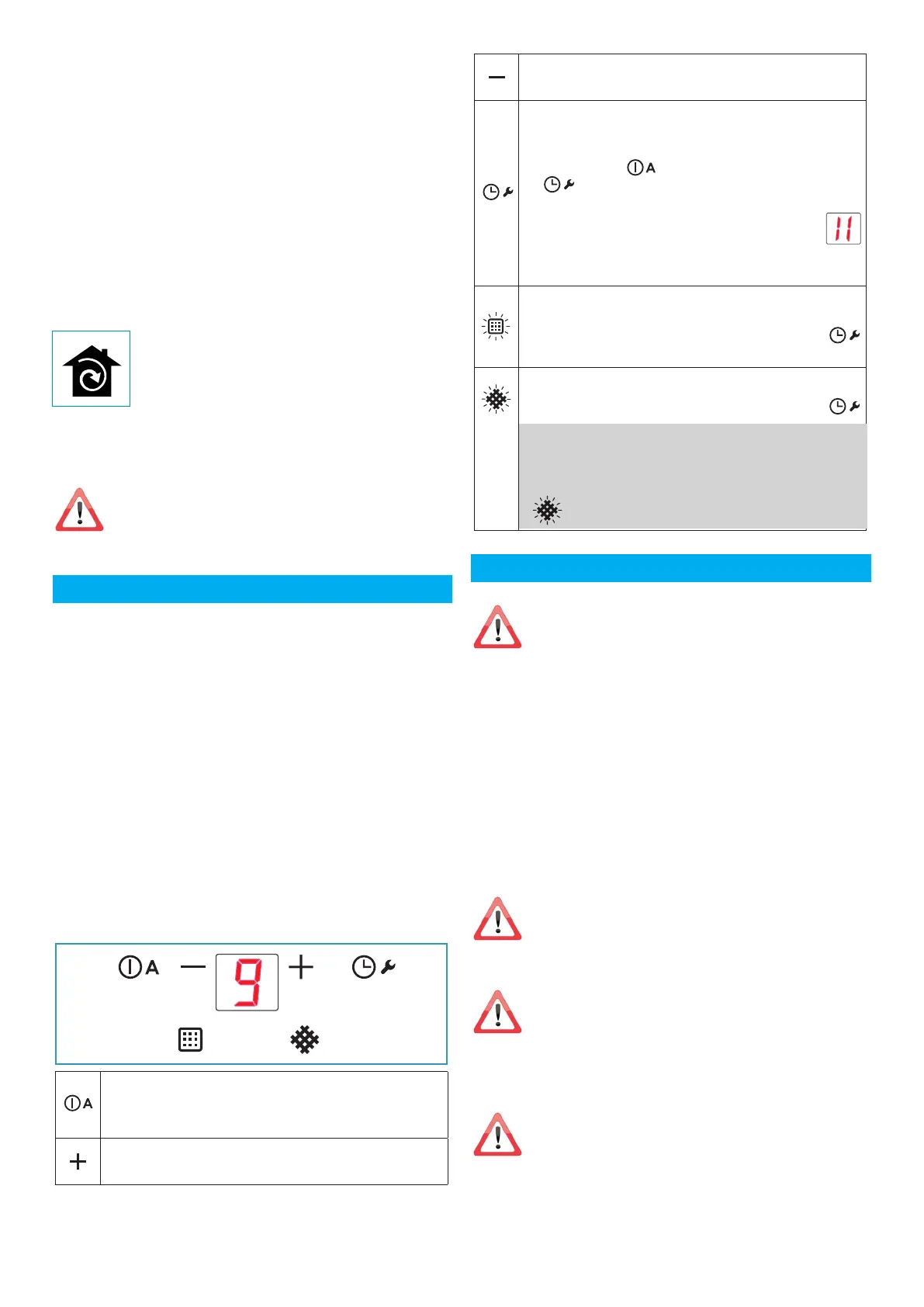

TOUCH PUSHBUTTON PANEL

ON/OFF

Short pulse: Hood switch ON/OFF

Long pulse: Hood operation automatic cycle activation (A) accor-

ding to plate power. (available only on M3 version).

Speed increase from 1 to…9 (up to “P”).

Speed “P”: active only for a few minutes, then speed 9.

Speed decrease from P to 1.

With hood active (short pulse): TIMER (flashing red LED)

Automatic switch-o after 15 min.

The function is disabled (red LED OFF) if:

- The motor is switched o (button ).

- Press the TIMER button

again .

With the hood OFF (long pulse 4s):

opening the fins for hood and metal filter maintenance

.

Hold down the key for 4 seconds to exit maintenance mode.

FAT METAL FILTER ALARM

Maintenance after about 30 hours’ use.

Press button

for 5 seconds to reset the counter.

CARBON.ZEO FILTER ALARM

Maintenance after about 2000 hours’ use.

Press button for 5 seconds to reset the counter.

To activate the alarm:

With the hood OFF, press the buttons and for 3 se-

conds.

The LED lights up.

Conrm with button

MAINTENANCE

Before cleaning or carrying out maintenance operations, discon-

nect the equipment by removing the plug or switching o the

main switch.

Do not use detergents containing abrasive, acidic or corrosive substances

or abrasive cloths.

Regular maintenance guarantees proper operation and performance over time.

Special attention is to be paid to the metal anti-grease lters: frequent clean-

ing of the filters and their supports ensures that no flammable grease is accu-

mulated.

CLEANING OF EXTERNAL SURFACES

You are advised to clean the external surfaces of the hood at least once every

15 days

to prevent oily substances and grease from sticking to them. To clean

the brushed stainless steel hood, the Manufacturer recommends using "Magic

Steel" wipes.

Alternatively and for all the other types of surfaces, it can be cleaned using a

damp cloth, slightly moistened with mild, liquid detergent or denatured alcohol.

Complete cleaning by rinsing well and drying with soft cloths.

Do not use too much moisture or water around the push button

control panel and lighting devices in order to prevent humidity

from reaching electronic parts.

The glass panels can only be cleaned with specific, non-corrosive or non-abra-

sive detergents using a soft cloth.

Do not wash the aps in a dishwasher.

The Manufacturer declines all responsibility for failure to comply with these in-

structions.

CLEANING OF INTERNAL SURFACES

Do not clean electrical parts, or parts related to the motor inside

the hood, with liquids or solvents.

For the internal metal parts, see the previous paragraph.

17

ENGLISH

The outlet pipe must have:

• a diameter not less than that of the hood fitting.

• a slight slope downwards (drop) in the horizontal sections to prevent conden-

sation from flowing back into the motor.

• the minimum required number of bends.

• the minimum required length to avoid vibrations and reduce the suction per-

formance of the hood.

You are required to insulate the pipes if it passes through cold environments.

In the presence of motors with 800m3/h or higher, a check valve is present to

prevent external air flowing back.

Deviation for Germany:

when the kitchen hood is used at the same time as appliances that are powered by

energy other than electricity, the negative pressure in the room must not exceed 4 Pa

(4 x 10-5 bar).

HOOD WITH INTERNAL RECIRCULATION FILTERING

In this model, the air passes through the charcoal filters (op-

tional) to be purified and recycled in the environment.

For assembly, see the instructions.

ASSEMBLY INSTRUCTIONS

only intended for qualied personnel

The hood can be installed in various congurations.

The generic assembly steps apply to all installations; for each case,

follow the specic steps provided for the required installation.

OPERATION

WHEN TO TURN ON THE HOOD?

Switch on the hood at least one minute before starting to cook to direct fumes

and vapours towards the suction surface.

After cooking, leave the hood operating until complete extraction of all vapours

and odours. By means of the Timer function, it is possible to set auto switch-off

function which will allow the hood to turn off automatically after 15 minutes of

operation.

WHICH SPEED IS TO BE SELECTED?

speed (1-3): maintains the circulation of clean air with low electricity consump-

tion.

speed (4-5): normal conditions of use.

speed (6-7): presence of strong odours and vapours.

speed (8-P): rapid disposal of odours and vapours.

WHEN SHOULD THE FILTERS BE WASHED OR REPLACED?

The metal filters must be cleaned every 30 hours of operation.

The active carbon filters must be replaced every 3-4 months, depending on the

use of the hood.

For further details see the “MAINTENANCE” chap.

TOUCH PUSHBUTTON PANEL

ON/OFF

Short pulse: Hood switch ON/OFF

Long pulse: Hood operation automatic cycle activation (A) accor-

ding to plate power. (available only on M3 version).

Speed increase from 1 to…9 (up to “P”).

Speed “P”: active only for a few minutes, then speed 9.

Speed decrease from P to 1.

With hood active (short pulse): TIMER (flashing red LED)

Automatic switch-o after 15 min.

The function is disabled (red LED OFF) if:

- The motor is switched o (button ).

- Press the TIMER button

again .

With the hood OFF (long pulse 4s):

opening the fins for hood and metal filter maintenance

.

Hold down the key for 4 seconds to exit maintenance mode.

FAT METAL FILTER ALARM

Maintenance after about 30 hours’ use.

Press button

for 5 seconds to reset the counter.

CARBON.ZEO FILTER ALARM

Maintenance after about 2000 hours’ use.

Press button for 5 seconds to reset the counter.

To activate the alarm:

With the hood OFF, press the buttons and for 3 se-

conds.

The LED lights up.

Conrm with button

MAINTENANCE

Before cleaning or carrying out maintenance operations, discon-

nect the equipment by removing the plug or switching o the

main switch.

Do not use detergents containing abrasive, acidic or corrosive substances

or abrasive cloths.

Regular maintenance guarantees proper operation and performance over time.

Special attention is to be paid to the metal anti-grease lters: frequent clean-

ing of the filters and their supports ensures that no flammable grease is accu-

mulated.

CLEANING OF EXTERNAL SURFACES

You are advised to clean the external surfaces of the hood at least once every

15 days

to prevent oily substances and grease from sticking to them. To clean

the brushed stainless steel hood, the Manufacturer recommends using "Magic

Steel" wipes.

Alternatively and for all the other types of surfaces, it can be cleaned using a

damp cloth, slightly moistened with mild, liquid detergent or denatured alcohol.

Complete cleaning by rinsing well and drying with soft cloths.

Do not use too much moisture or water around the push button

control panel and lighting devices in order to prevent humidity

from reaching electronic parts.

The glass panels can only be cleaned with specific, non-corrosive or non-abra-

sive detergents using a soft cloth.

Do not wash the aps in a dishwasher.

The Manufacturer declines all responsibility for failure to comply with these in-

structions.

CLEANING OF INTERNAL SURFACES

Do not clean electrical parts, or parts related to the motor inside

the hood, with liquids or solvents.

For the internal metal parts, see the previous paragraph.

9

ITALIANO

COLLEGAMENTO ELETTRICO

(parte riservata solo a personale qualicato)

Prima di eettuare qualsiasi operazione sulla cappa scollegare l’apparec-

chio dalla rete elettrica.

Assicurarsi che non vengano scollegati o tagliati li elettrici all’interno della

cappa:

in caso contrario contattare il Centro Assistenza più vicino.

Per l’allacciamento elettrico rivolgersi a personale qualicato.

Il collegamento deve essere eseguito in conformità con le disposizioni di legge in

vigore.

Prima di collegare la cappa alla rete elettrica, controllare che:

cappa;

posizionate all’interno della cappa);

superiori a 70 °C;

-

condo le norme vigenti;

la presa usata per il collegamento sia facilmente raggiungibile una volta installata la cappa.

In caso di :

-

zato”. Il li devono essere collegati come segue: giallo-verde per la messa a terra, blu per

il neutro e il lo marrone per la fase. La spina deve essere collegata ad un'adeguata presa

di sicurezza.

apparecchio sso non provvisto di cavo di alimentazione e di spina, o di altro dispositivo

che assicuri la disconnessione dalla rete, con una distanza di apertura dei contatti che

consenta la disconnessione completa nelle condizioni della categoria di sovratensione III.

Tali dispositivi di disconnessione devono essere previsti nella rete di alimentazione con-

formemente alle regole di installazione.

Il cavo di terra giallo/verde non deve essere interrotto dall’interruttore.

Il Costruttore declina ogni responsabilità nel caso le norme di sicurezza non vengano ri-

spettate.

SCARICO FUMI

CAPPA AD EVACUAZIONE ESTERNA ASPIRANTE

In questa versione, fumi e vapori vengono convogliati verso l'esterno

attraverso il tubo di scarico.

A tal ne, il raccordo d'uscita della cappa, deve essere collegato tramite

un tubo, ad un'uscita esterna.

Il tubo d'uscita deve avere:

condensa reuisca nel motore.

-

te della cappa.

E' necessario isolare la tubazione se passa attraverso ambienti freddi.

Per impedire ritorni d'aria dall'esterno, una valvola di non ritorno è presente in presenza

di motori con 800m

3

/h o superiori.

Deviazione per la Germania:

quando la cappa da cucina e apparecchi alimentati con energia diversa da quella elettrica sono

in funzione simultaneamente, la pressione negativa nel locale non deve superare i 4 Pa (4 x 10-5

bar).

CAPPA A RICICLO INTERNO FILTRANTE

In questa versione l’aria passa attraverso i ltri al carbone attivo HP (op-

zionali) per essere puricata e riciclata nell’ambiente.

Controllare che i ltri al carbone attivo HP siano montati sulla cappa, in

caso negativo applicarli come indicato nelle istruzioni di montaggio.

In questa versione valvola di non ritorno non deve essere montata: rimuoverla se

presente sul raccordo di uscita aria del motore.

ISTRUZIONI DI MONTAGGIO

parte riservata solo a personale qualicato

La cappa ha la possibilità di essere installata in varie congurazioni.

Le fasi di montaggio generiche valgono per tutte le installazioni; seguire

invece dove specicato le fasi corrispondenti all’installazione desiderata.

FUNZIONAMENTO

QUANDO ACCENDERE LA CAPPA?

Accendere la cappa almeno un minuto prima di iniziare a cucinare per convogliare fumi e

vapori verso la supercie di aspirazione.

Al termine della cottura lasciare in funzione la cappa no a completa aspirazione di tutti i

vapori e odori: con la funzione Timer, è possibile impostare l'autospegnimento della cappa

dopo 15 minuti di funzionamento.

QUALE VELOCITÀ SCEGLIERE?

I velocità: mantiene l’aria pulita con bassi consumi di energia elettrica.

II velocità: condizioni normali di utilizzo.

III velocità: presenza di forti odori e vapori.

IV velocità: rapidi smaltimenti di odori e vapori.

QUANDO LAVARE O CAMBIARE I FILTRI?

I ltri metallici devono essere lavati ogni 30 ore di utilizzo.

I ltri carbone attivo, vanno sostituiti ogni 3-4 mesi a seconda dell’utilizzo della cappa.

Per ulteriori dettagli vedere cap “MANUTENZIONE”.

PULSANTIERA ELETTRONICA

Motore ON/OFF

All’avvio, la velocità è quella memorizzata al precedente spegnimento.

Incremento velocità da 1 a 4

Velocità 4 è attiva solo per alcuni mi-

nuti, poi si attiva velocità 3.

Le velocità sono segnalate dai led

presenti nei tasti:

Velocità 1

Velocità 2

Velocità 3

Velocità 4

(led "+" lampeggiante)

Riduzione velocità da 4 a 1

Accensione / spegnimento luce

TIMER (Led rosso lampeggiante)

Autospegnimento dopo 15min.

La funzione si disattiva (Led rosso spento) se:

- Si preme un'altra volta il tasto TIMER (

).

- Si preme il tasto ON/OFF (

).

ALLARME FILTRI (Led rosso sso con (

) o )

Manutenzione ltri antigrasso dopo circa 30 ore di utilizzo.

Premere (

) per 3 secondi per azzerare il contatore.

17

ENGLISH

The outlet pipe must have:

• a diameter not less than that of the hood fitting.

• a slight slope downwards (drop) in the horizontal sections to prevent conden-

sation from flowing back into the motor.

• the minimum required number of bends.

• the minimum required length to avoid vibrations and reduce the suction per-

formance of the hood.

You are required to insulate the pipes if it passes through cold environments.

In the presence of motors with 800m3/h or higher, a check valve is present to

prevent external air flowing back.

Deviation for Germany:

when the kitchen hood is used at the same time as appliances that are powered by

energy other than electricity, the negative pressure in the room must not exceed 4 Pa

(4 x 10-5 bar).

HOOD WITH INTERNAL RECIRCULATION FILTERING

In this model, the air passes through the charcoal filters (op-

tional) to be purified and recycled in the environment.

For assembly, see the instructions.

ASSEMBLY INSTRUCTIONS

only intended for qualied personnel

The hood can be installed in various congurations.

The generic assembly steps apply to all installations; for each case,

follow the specic steps provided for the required installation.

OPERATION

WHEN TO TURN ON THE HOOD?

Switch on the hood at least one minute before starting to cook to direct fumes

and vapours towards the suction surface.

After cooking, leave the hood operating until complete extraction of all vapours

and odours. By means of the Timer function, it is possible to set auto switch-off

function which will allow the hood to turn off automatically after 15 minutes of

operation.

WHICH SPEED IS TO BE SELECTED?

speed (1-3): maintains the circulation of clean air with low electricity consump-

tion.

speed (4-5): normal conditions of use.

speed (6-7): presence of strong odours and vapours.

speed (8-P): rapid disposal of odours and vapours.

WHEN SHOULD THE FILTERS BE WASHED OR REPLACED?

The metal filters must be cleaned every 30 hours of operation.

The active carbon filters must be replaced every 3-4 months, depending on the

use of the hood.

For further details see the “MAINTENANCE” chap.

TOUCH PUSHBUTTON PANEL

ON/OFF

Short pulse: Hood switch ON/OFF

Long pulse: Hood operation automatic cycle activation (A) accor-

ding to plate power. (available only on M3 version).

Speed increase from 1 to…9 (up to “P”).

Speed “P”: active only for a few minutes, then speed 9.

Speed decrease from P to 1.

With hood active (short pulse): TIMER (flashing red LED)

Automatic switch-o after 15 min.

The function is disabled (red LED OFF) if:

- The motor is switched o (button ).

- Press the TIMER button again .

With the hood OFF (long pulse 4s):

opening the fins for hood and metal filter maintenance .

Hold down the key for 4 seconds to exit maintenance mode.

FAT METAL FILTER ALARM

Maintenance after about 30 hours’ use.

Press button for 5 seconds to reset the counter.

CARBON.ZEO FILTER ALARM

Maintenance after about 2000 hours’ use.

Press button for 5 seconds to reset the counter.

To activate the alarm:

With the hood OFF, press the buttons and for 3 se-

conds.

The LED lights up.

Conrm with button

MAINTENANCE

Before cleaning or carrying out maintenance operations, discon-

nect the equipment by removing the plug or switching o the

main switch.

Do not use detergents containing abrasive, acidic or corrosive substances

or abrasive cloths.

Regular maintenance guarantees proper operation and performance over time.

Special attention is to be paid to the metal anti-grease lters: frequent clean-

ing of the filters and their supports ensures that no flammable grease is accu-

mulated.

CLEANING OF EXTERNAL SURFACES

You are advised to clean the external surfaces of the hood at least once every

15 days

to prevent oily substances and grease from sticking to them. To clean

the brushed stainless steel hood, the Manufacturer recommends using "Magic

Steel" wipes.

Alternatively and for all the other types of surfaces, it can be cleaned using a

damp cloth, slightly moistened with mild, liquid detergent or denatured alcohol.

Complete cleaning by rinsing well and drying with soft cloths.

Do not use too much moisture or water around the push button

control panel and lighting devices in order to prevent humidity

from reaching electronic parts.

The glass panels can only be cleaned with specific, non-corrosive or non-abra-

sive detergents using a soft cloth.

Do not wash the aps in a dishwasher.

The Manufacturer declines all responsibility for failure to comply with these in-

structions.

CLEANING OF INTERNAL SURFACES

Do not clean electrical parts, or parts related to the motor inside

the hood, with liquids or solvents.

For the internal metal parts, see the previous paragraph.

17

ENGLISH

The outlet pipe must have:

• a diameter not less than that of the hood fitting.

• a slight slope downwards (drop) in the horizontal sections to prevent conden-

sation from flowing back into the motor.

• the minimum required number of bends.

• the minimum required length to avoid vibrations and reduce the suction per-

formance of the hood.

You are required to insulate the pipes if it passes through cold environments.

In the presence of motors with 800m3/h or higher, a check valve is present to

prevent external air flowing back.

Deviation for Germany:

when the kitchen hood is used at the same time as appliances that are powered by

energy other than electricity, the negative pressure in the room must not exceed 4 Pa

(4 x 10-5 bar).

HOOD WITH INTERNAL RECIRCULATION FILTERING

In this model, the air passes through the charcoal filters (op-

tional) to be purified and recycled in the environment.

For assembly, see the instructions.

ASSEMBLY INSTRUCTIONS

only intended for qualied personnel

The hood can be installed in various congurations.

The generic assembly steps apply to all installations; for each case,

follow the specic steps provided for the required installation.

OPERATION

WHEN TO TURN ON THE HOOD?

Switch on the hood at least one minute before starting to cook to direct fumes

and vapours towards the suction surface.

After cooking, leave the hood operating until complete extraction of all vapours

and odours. By means of the Timer function, it is possible to set auto switch-off

function which will allow the hood to turn off automatically after 15 minutes of

operation.

WHICH SPEED IS TO BE SELECTED?

speed (1-3): maintains the circulation of clean air with low electricity consump-

tion.

speed (4-5): normal conditions of use.

speed (6-7): presence of strong odours and vapours.

speed (8-P): rapid disposal of odours and vapours.

WHEN SHOULD THE FILTERS BE WASHED OR REPLACED?

The metal filters must be cleaned every 30 hours of operation.

The active carbon filters must be replaced every 3-4 months, depending on the

use of the hood.

For further details see the “MAINTENANCE” chap.

TOUCH PUSHBUTTON PANEL

ON/OFF

Short pulse: Hood switch ON/OFF

Long pulse: Hood operation automatic cycle activation (A) accor-

ding to plate power. (available only on M3 version).

Speed increase from 1 to…9 (up to “P”).

Speed “P”: active only for a few minutes, then speed 9.

Speed decrease from P to 1.

With hood active (short pulse): TIMER (flashing red LED)

Automatic switch-o after 15 min.

The function is disabled (red LED OFF) if:

- The motor is switched o (button ).

- Press the TIMER button again .

With the hood OFF (long pulse 4s):

opening the fins for hood and metal filter maintenance .

Hold down the key for 4 seconds to exit maintenance mode.

FAT METAL FILTER ALARM

Maintenance after about 30 hours’ use.

Press button for 5 seconds to reset the counter.

CARBON.ZEO FILTER ALARM

Maintenance after about 2000 hours’ use.

Press button for 5 seconds to reset the counter.

To activate the alarm:

With the hood OFF, press the buttons and for 3 se-

conds.

The LED lights up.

Conrm with button

MAINTENANCE

Before cleaning or carrying out maintenance operations, discon-

nect the equipment by removing the plug or switching o the

main switch.

Do not use detergents containing abrasive, acidic or corrosive substances

or abrasive cloths.

Regular maintenance guarantees proper operation and performance over time.

Special attention is to be paid to the metal anti-grease lters: frequent clean-

ing of the filters and their supports ensures that no flammable grease is accu-

mulated.

CLEANING OF EXTERNAL SURFACES

You are advised to clean the external surfaces of the hood at least once every

15 days

to prevent oily substances and grease from sticking to them. To clean

the brushed stainless steel hood, the Manufacturer recommends using "Magic

Steel" wipes.

Alternatively and for all the other types of surfaces, it can be cleaned using a

damp cloth, slightly moistened with mild, liquid detergent or denatured alcohol.

Complete cleaning by rinsing well and drying with soft cloths.

Do not use too much moisture or water around the push button

control panel and lighting devices in order to prevent humidity

from reaching electronic parts.

The glass panels can only be cleaned with specific, non-corrosive or non-abra-

sive detergents using a soft cloth.

Do not wash the aps in a dishwasher.

The Manufacturer declines all responsibility for failure to comply with these in-

structions.

CLEANING OF INTERNAL SURFACES

Do not clean electrical parts, or parts related to the motor inside

the hood, with liquids or solvents.

For the internal metal parts, see the previous paragraph.

+

–

17

ENGLISH

The outlet pipe must have:

• a diameter not less than that of the hood fitting.

• a slight slope downwards (drop) in the horizontal sections to prevent conden-

sation from flowing back into the motor.

• the minimum required number of bends.

• the minimum required length to avoid vibrations and reduce the suction per-

formance of the hood.

You are required to insulate the pipes if it passes through cold environments.

In the presence of motors with 800m3/h or higher, a check valve is present to

prevent external air flowing back.

Deviation for Germany:

when the kitchen hood is used at the same time as appliances that are powered by

energy other than electricity, the negative pressure in the room must not exceed 4 Pa

(4 x 10-5 bar).

HOOD WITH INTERNAL RECIRCULATION FILTERING

In this model, the air passes through the charcoal filters (op-

tional) to be purified and recycled in the environment.

For assembly, see the instructions.

ASSEMBLY INSTRUCTIONS

only intended for qualied personnel

The hood can be installed in various congurations.

The generic assembly steps apply to all installations; for each case,

follow the specic steps provided for the required installation.

OPERATION

WHEN TO TURN ON THE HOOD?

Switch on the hood at least one minute before starting to cook to direct fumes

and vapours towards the suction surface.

After cooking, leave the hood operating until complete extraction of all vapours

and odours. By means of the Timer function, it is possible to set auto switch-off

function which will allow the hood to turn off automatically after 15 minutes of

operation.

WHICH SPEED IS TO BE SELECTED?

speed (1-3): maintains the circulation of clean air with low electricity consump-

tion.

speed (4-5): normal conditions of use.

speed (6-7): presence of strong odours and vapours.

speed (8-P): rapid disposal of odours and vapours.

WHEN SHOULD THE FILTERS BE WASHED OR REPLACED?

The metal filters must be cleaned every 30 hours of operation.

The active carbon filters must be replaced every 3-4 months, depending on the

use of the hood.

For further details see the “MAINTENANCE” chap.

TOUCH PUSHBUTTON PANEL

ON/OFF

Short pulse: Hood switch ON/OFF

Long pulse: Hood operation automatic cycle activation (A) accor-

ding to plate power. (available only on M3 version).

Speed increase from 1 to…9 (up to “P”).

Speed “P”: active only for a few minutes, then speed 9.

Speed decrease from P to 1.

With hood active (short pulse): TIMER (flashing red LED)

Automatic switch-o after 15 min.

The function is disabled (red LED OFF) if:

- The motor is switched o (button

).

- Press the TIMER button again .

With the hood OFF (long pulse 4s):

opening the fins for hood and metal filter maintenance .

Hold down the key for 4 seconds to exit maintenance mode.

FAT METAL FILTER ALARM

Maintenance after about 30 hours’ use.

Press button for 5 seconds to reset the counter.

CARBON.ZEO FILTER ALARM

Maintenance after about 2000 hours’ use.

Press button

for 5 seconds to reset the counter.

To activate the alarm:

With the hood OFF, press the buttons and for 3 se-

conds.

The LED lights up.

Conrm with button

MAINTENANCE

Before cleaning or carrying out maintenance operations, discon-

nect the equipment by removing the plug or switching o the

main switch.

Do not use detergents containing abrasive, acidic or corrosive substances

or abrasive cloths.

Regular maintenance guarantees proper operation and performance over time.

Special attention is to be paid to the metal anti-grease lters: frequent clean-

ing of the filters and their supports ensures that no flammable grease is accu-

mulated.

CLEANING OF EXTERNAL SURFACES

You are advised to clean the external surfaces of the hood at least once every

15 days

to prevent oily substances and grease from sticking to them. To clean

the brushed stainless steel hood, the Manufacturer recommends using "Magic

Steel" wipes.

Alternatively and for all the other types of surfaces, it can be cleaned using a

damp cloth, slightly moistened with mild, liquid detergent or denatured alcohol.

Complete cleaning by rinsing well and drying with soft cloths.

Do not use too much moisture or water around the push button

control panel and lighting devices in order to prevent humidity

from reaching electronic parts.

The glass panels can only be cleaned with specific, non-corrosive or non-abra-

sive detergents using a soft cloth.

Do not wash the aps in a dishwasher.

The Manufacturer declines all responsibility for failure to comply with these in-

structions.

CLEANING OF INTERNAL SURFACES

Do not clean electrical parts, or parts related to the motor inside

the hood, with liquids or solvents.

For the internal metal parts, see the previous paragraph.

+

17

ENGLISH

The outlet pipe must have:

• a diameter not less than that of the hood fitting.

• a slight slope downwards (drop) in the horizontal sections to prevent conden-

sation from flowing back into the motor.

• the minimum required number of bends.

• the minimum required length to avoid vibrations and reduce the suction per-

formance of the hood.

You are required to insulate the pipes if it passes through cold environments.

In the presence of motors with 800m3/h or higher, a check valve is present to

prevent external air flowing back.

Deviation for Germany:

when the kitchen hood is used at the same time as appliances that are powered by

energy other than electricity, the negative pressure in the room must not exceed 4 Pa

(4 x 10-5 bar).

HOOD WITH INTERNAL RECIRCULATION FILTERING

In this model, the air passes through the charcoal filters (op-

tional) to be purified and recycled in the environment.

For assembly, see the instructions.

ASSEMBLY INSTRUCTIONS

only intended for qualied personnel

The hood can be installed in various congurations.

The generic assembly steps apply to all installations; for each case,

follow the specic steps provided for the required installation.

OPERATION

WHEN TO TURN ON THE HOOD?

Switch on the hood at least one minute before starting to cook to direct fumes

and vapours towards the suction surface.

After cooking, leave the hood operating until complete extraction of all vapours

and odours. By means of the Timer function, it is possible to set auto switch-off

function which will allow the hood to turn off automatically after 15 minutes of

operation.

WHICH SPEED IS TO BE SELECTED?

speed (1-3): maintains the circulation of clean air with low electricity consump-

tion.

speed (4-5): normal conditions of use.

speed (6-7): presence of strong odours and vapours.

speed (8-P): rapid disposal of odours and vapours.

WHEN SHOULD THE FILTERS BE WASHED OR REPLACED?

The metal filters must be cleaned every 30 hours of operation.

The active carbon filters must be replaced every 3-4 months, depending on the

use of the hood.

For further details see the “MAINTENANCE” chap.

TOUCH PUSHBUTTON PANEL

ON/OFF

Short pulse: Hood switch ON/OFF

Long pulse: Hood operation automatic cycle activation (A) accor-

ding to plate power. (available only on M3 version).

Speed increase from 1 to…9 (up to “P”).

Speed “P”: active only for a few minutes, then speed 9.

Speed decrease from P to 1.

With hood active (short pulse): TIMER (flashing red LED)

Automatic switch-o after 15 min.

The function is disabled (red LED OFF) if:

- The motor is switched o (button

).

- Press the TIMER button

again .

With the hood OFF (long pulse 4s):

opening the fins for hood and metal filter maintenance

.

Hold down the key for 4 seconds to exit maintenance mode.

FAT METAL FILTER ALARM

Maintenance after about 30 hours’ use.

Press button

for 5 seconds to reset the counter.

CARBON.ZEO FILTER ALARM

Maintenance after about 2000 hours’ use.

Press button for 5 seconds to reset the counter.

To activate the alarm:

With the hood OFF, press the buttons and for 3 se-

conds.

The LED lights up.

Conrm with button

MAINTENANCE

Before cleaning or carrying out maintenance operations, discon-

nect the equipment by removing the plug or switching o the

main switch.

Do not use detergents containing abrasive, acidic or corrosive substances

or abrasive cloths.

Regular maintenance guarantees proper operation and performance over time.

Special attention is to be paid to the metal anti-grease lters: frequent clean-

ing of the filters and their supports ensures that no flammable grease is accu-

mulated.

CLEANING OF EXTERNAL SURFACES

You are advised to clean the external surfaces of the hood at least once every

15 days

to prevent oily substances and grease from sticking to them. To clean

the brushed stainless steel hood, the Manufacturer recommends using "Magic

Steel" wipes.

Alternatively and for all the other types of surfaces, it can be cleaned using a

damp cloth, slightly moistened with mild, liquid detergent or denatured alcohol.

Complete cleaning by rinsing well and drying with soft cloths.

Do not use too much moisture or water around the push button

control panel and lighting devices in order to prevent humidity

from reaching electronic parts.

The glass panels can only be cleaned with specific, non-corrosive or non-abra-

sive detergents using a soft cloth.

Do not wash the aps in a dishwasher.

The Manufacturer declines all responsibility for failure to comply with these in-

structions.

CLEANING OF INTERNAL SURFACES

Do not clean electrical parts, or parts related to the motor inside

the hood, with liquids or solvents.

For the internal metal parts, see the previous paragraph.

17

ENGLISH

The outlet pipe must have:

• a diameter not less than that of the hood fitting.

• a slight slope downwards (drop) in the horizontal sections to prevent conden-

sation from flowing back into the motor.

• the minimum required number of bends.

• the minimum required length to avoid vibrations and reduce the suction per-

formance of the hood.

You are required to insulate the pipes if it passes through cold environments.

In the presence of motors with 800m3/h or higher, a check valve is present to

prevent external air flowing back.

Deviation for Germany:

when the kitchen hood is used at the same time as appliances that are powered by

energy other than electricity, the negative pressure in the room must not exceed 4 Pa

(4 x 10-5 bar).

HOOD WITH INTERNAL RECIRCULATION FILTERING

In this model, the air passes through the charcoal filters (op-

tional) to be purified and recycled in the environment.

For assembly, see the instructions.

ASSEMBLY INSTRUCTIONS

only intended for qualied personnel

The hood can be installed in various congurations.

The generic assembly steps apply to all installations; for each case,

follow the specic steps provided for the required installation.

OPERATION

WHEN TO TURN ON THE HOOD?

Switch on the hood at least one minute before starting to cook to direct fumes

and vapours towards the suction surface.

After cooking, leave the hood operating until complete extraction of all vapours

and odours. By means of the Timer function, it is possible to set auto switch-off

function which will allow the hood to turn off automatically after 15 minutes of

operation.

WHICH SPEED IS TO BE SELECTED?

speed (1-3): maintains the circulation of clean air with low electricity consump-

tion.

speed (4-5): normal conditions of use.

speed (6-7): presence of strong odours and vapours.

speed (8-P): rapid disposal of odours and vapours.

WHEN SHOULD THE FILTERS BE WASHED OR REPLACED?

The metal filters must be cleaned every 30 hours of operation.

The active carbon filters must be replaced every 3-4 months, depending on the

use of the hood.

For further details see the “MAINTENANCE” chap.

TOUCH PUSHBUTTON PANEL

ON/OFF

Short pulse: Hood switch ON/OFF

Long pulse: Hood operation automatic cycle activation (A) accor-

ding to plate power. (available only on M3 version).

Speed increase from 1 to…9 (up to “P”).

Speed “P”: active only for a few minutes, then speed 9.

Speed decrease from P to 1.

With hood active (short pulse): TIMER (flashing red LED)

Automatic switch-o after 15 min.

The function is disabled (red LED OFF) if:

- The motor is switched o (button

).

- Press the TIMER button again .

With the hood OFF (long pulse 4s):

opening the fins for hood and metal filter maintenance .

Hold down the key for 4 seconds to exit maintenance mode.

FAT METAL FILTER ALARM

Maintenance after about 30 hours’ use.

Press button for 5 seconds to reset the counter.

CARBON.ZEO FILTER ALARM

Maintenance after about 2000 hours’ use.

Press button for 5 seconds to reset the counter.

To activate the alarm:

With the hood OFF, press the buttons and for 3 se-

conds.

The LED lights up.

Conrm with button

MAINTENANCE

Before cleaning or carrying out maintenance operations, discon-

nect the equipment by removing the plug or switching o the

main switch.

Do not use detergents containing abrasive, acidic or corrosive substances

or abrasive cloths.

Regular maintenance guarantees proper operation and performance over time.

Special attention is to be paid to the metal anti-grease lters: frequent clean-

ing of the filters and their supports ensures that no flammable grease is accu-

mulated.

CLEANING OF EXTERNAL SURFACES

You are advised to clean the external surfaces of the hood at least once every

15 days

to prevent oily substances and grease from sticking to them. To clean

the brushed stainless steel hood, the Manufacturer recommends using "Magic

Steel" wipes.

Alternatively and for all the other types of surfaces, it can be cleaned using a

damp cloth, slightly moistened with mild, liquid detergent or denatured alcohol.

Complete cleaning by rinsing well and drying with soft cloths.

Do not use too much moisture or water around the push button

control panel and lighting devices in order to prevent humidity

from reaching electronic parts.

The glass panels can only be cleaned with specific, non-corrosive or non-abra-

sive detergents using a soft cloth.

Do not wash the aps in a dishwasher.

The Manufacturer declines all responsibility for failure to comply with these in-

structions.

CLEANING OF INTERNAL SURFACES

Do not clean electrical parts, or parts related to the motor inside

the hood, with liquids or solvents.

For the internal metal parts, see the previous paragraph.

17

ENGLISH

The outlet pipe must have:

• a diameter not less than that of the hood fitting.

• a slight slope downwards (drop) in the horizontal sections to prevent conden-

sation from flowing back into the motor.

• the minimum required number of bends.

• the minimum required length to avoid vibrations and reduce the suction per-

formance of the hood.

You are required to insulate the pipes if it passes through cold environments.

In the presence of motors with 800m3/h or higher, a check valve is present to

prevent external air flowing back.

Deviation for Germany:

when the kitchen hood is used at the same time as appliances that are powered by

energy other than electricity, the negative pressure in the room must not exceed 4 Pa

(4 x 10-5 bar).

HOOD WITH INTERNAL RECIRCULATION FILTERING

In this model, the air passes through the charcoal filters (op-

tional) to be purified and recycled in the environment.

For assembly, see the instructions.

ASSEMBLY INSTRUCTIONS

only intended for qualied personnel

The hood can be installed in various congurations.

The generic assembly steps apply to all installations; for each case,

follow the specic steps provided for the required installation.

OPERATION

WHEN TO TURN ON THE HOOD?

Switch on the hood at least one minute before starting to cook to direct fumes

and vapours towards the suction surface.

After cooking, leave the hood operating until complete extraction of all vapours

and odours. By means of the Timer function, it is possible to set auto switch-off

function which will allow the hood to turn off automatically after 15 minutes of

operation.

WHICH SPEED IS TO BE SELECTED?

speed (1-3): maintains the circulation of clean air with low electricity consump-

tion.

speed (4-5): normal conditions of use.

speed (6-7): presence of strong odours and vapours.

speed (8-P): rapid disposal of odours and vapours.

WHEN SHOULD THE FILTERS BE WASHED OR REPLACED?

The metal filters must be cleaned every 30 hours of operation.

The active carbon filters must be replaced every 3-4 months, depending on the

use of the hood.

For further details see the “MAINTENANCE” chap.

TOUCH PUSHBUTTON PANEL

ON/OFF

Short pulse: Hood switch ON/OFF

Long pulse: Hood operation automatic cycle activation (A) accor-

ding to plate power. (available only on M3 version).

Speed increase from 1 to…9 (up to “P”).

Speed “P”: active only for a few minutes, then speed 9.

Speed decrease from P to 1.

With hood active (short pulse): TIMER (flashing red LED)

Automatic switch-o after 15 min.

The function is disabled (red LED OFF) if:

- The motor is switched o (button ).

- Press the TIMER button again .

With the hood OFF (long pulse 4s):

opening the fins for hood and metal filter maintenance .

Hold down the key for 4 seconds to exit maintenance mode.

FAT METAL FILTER ALARM

Maintenance after about 30 hours’ use.

Press button for 5 seconds to reset the counter.

CARBON.ZEO FILTER ALARM

Maintenance after about 2000 hours’ use.

Press button for 5 seconds to reset the counter.

To activate the alarm:

With the hood OFF, press the buttons and for 3 se-

conds.

The LED lights up.

Conrm with button

MAINTENANCE

Before cleaning or carrying out maintenance operations, discon-

nect the equipment by removing the plug or switching o the

main switch.

Do not use detergents containing abrasive, acidic or corrosive substances

or abrasive cloths.

Regular maintenance guarantees proper operation and performance over time.

Special attention is to be paid to the metal anti-grease lters: frequent clean-

ing of the filters and their supports ensures that no flammable grease is accu-

mulated.

CLEANING OF EXTERNAL SURFACES

You are advised to clean the external surfaces of the hood at least once every

15 days

to prevent oily substances and grease from sticking to them. To clean

the brushed stainless steel hood, the Manufacturer recommends using "Magic

Steel" wipes.

Alternatively and for all the other types of surfaces, it can be cleaned using a

damp cloth, slightly moistened with mild, liquid detergent or denatured alcohol.

Complete cleaning by rinsing well and drying with soft cloths.

Do not use too much moisture or water around the push button

control panel and lighting devices in order to prevent humidity

from reaching electronic parts.

The glass panels can only be cleaned with specific, non-corrosive or non-abra-

sive detergents using a soft cloth.

Do not wash the aps in a dishwasher.

The Manufacturer declines all responsibility for failure to comply with these in-

structions.

CLEANING OF INTERNAL SURFACES

Do not clean electrical parts, or parts related to the motor inside

the hood, with liquids or solvents.

For the internal metal parts, see the previous paragraph.

Loading...

Loading...