Electrical Connection

DO NOT CONNECT POWER SUPPLY UNTIL SWITCH IS COMPLETELY INSTALLED. MAKE SURE ELECTRICAL

SERVICE TO THE SWITCH IS LOCKED IN "OFF" POSITION.

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS - OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the factory.

2. Before servicing or cleaning, switch power off at service panel and lock service panel to prevent circuit from being switched

on accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent warning device, such

as a tag, to the service panel.

3. Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable codes and

standards, including fire-rated construction.

4. When cutting or drilling into wall or ceiling, do not damage electrical wires or other hidden utilities.

Note: DB10 is suitable for use only with the following fans:

FR100, 110, 125, 140, 150, 160, 200, 225; K/FX4, 4XL, 5, 5XL, 6, 6XL,

8, 8XL, 10; RVF4, 4XL, 6, 6XL, 8XL; RE(C)/KRD(C) 6, 8XL.

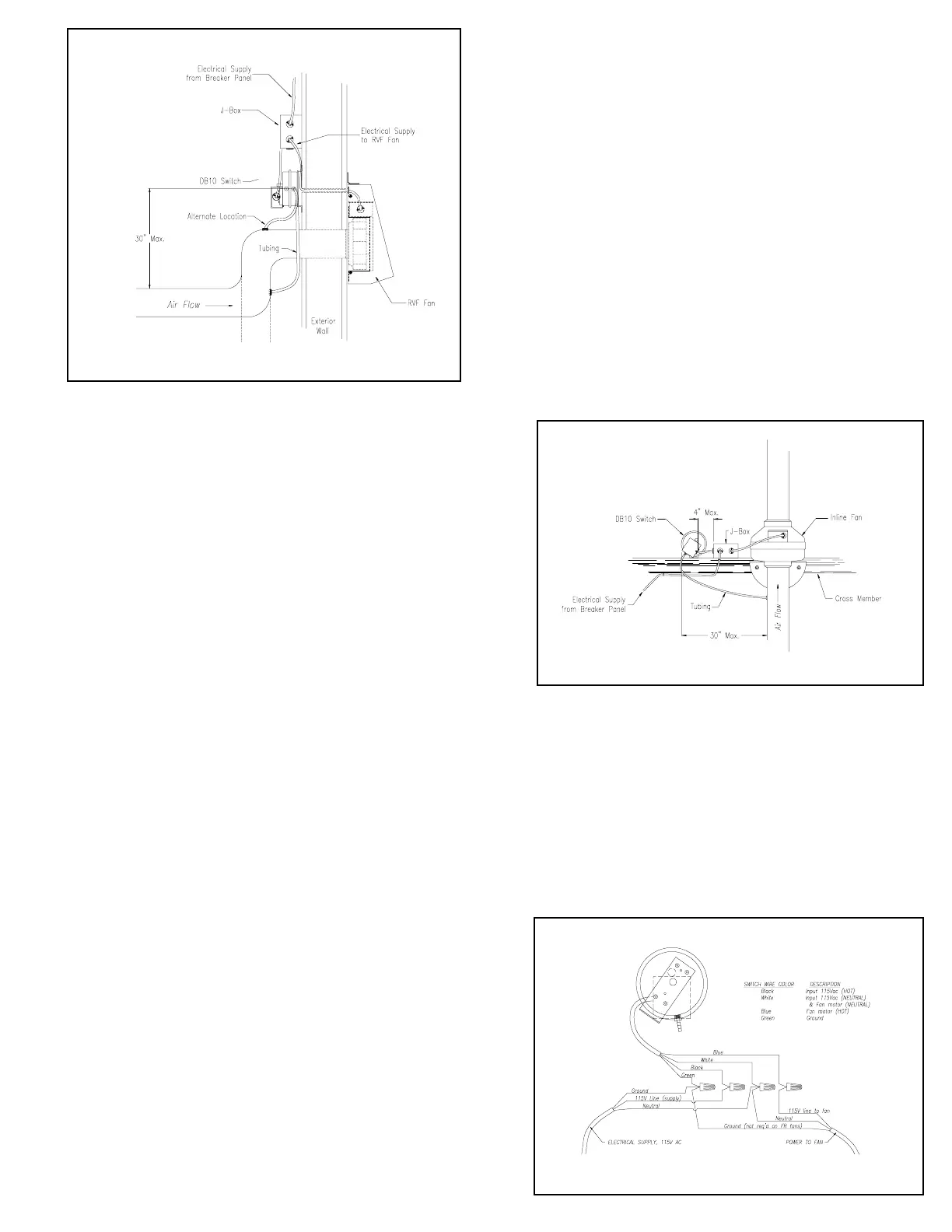

Wiring Procedure

Step 1.

A 4”x4” junction box (J-Box) is recommended for adequate

space for all wiring connections. The box should be mounted a

maximum of 4 inches from the switch. (Refer to illustrations above.)

Step 2.

Using the wire nuts provided, connect the incoming

electrical supply, the switch leads and the power supply to fan as

shown in the schematic on the right.

Additional Installation Notes:

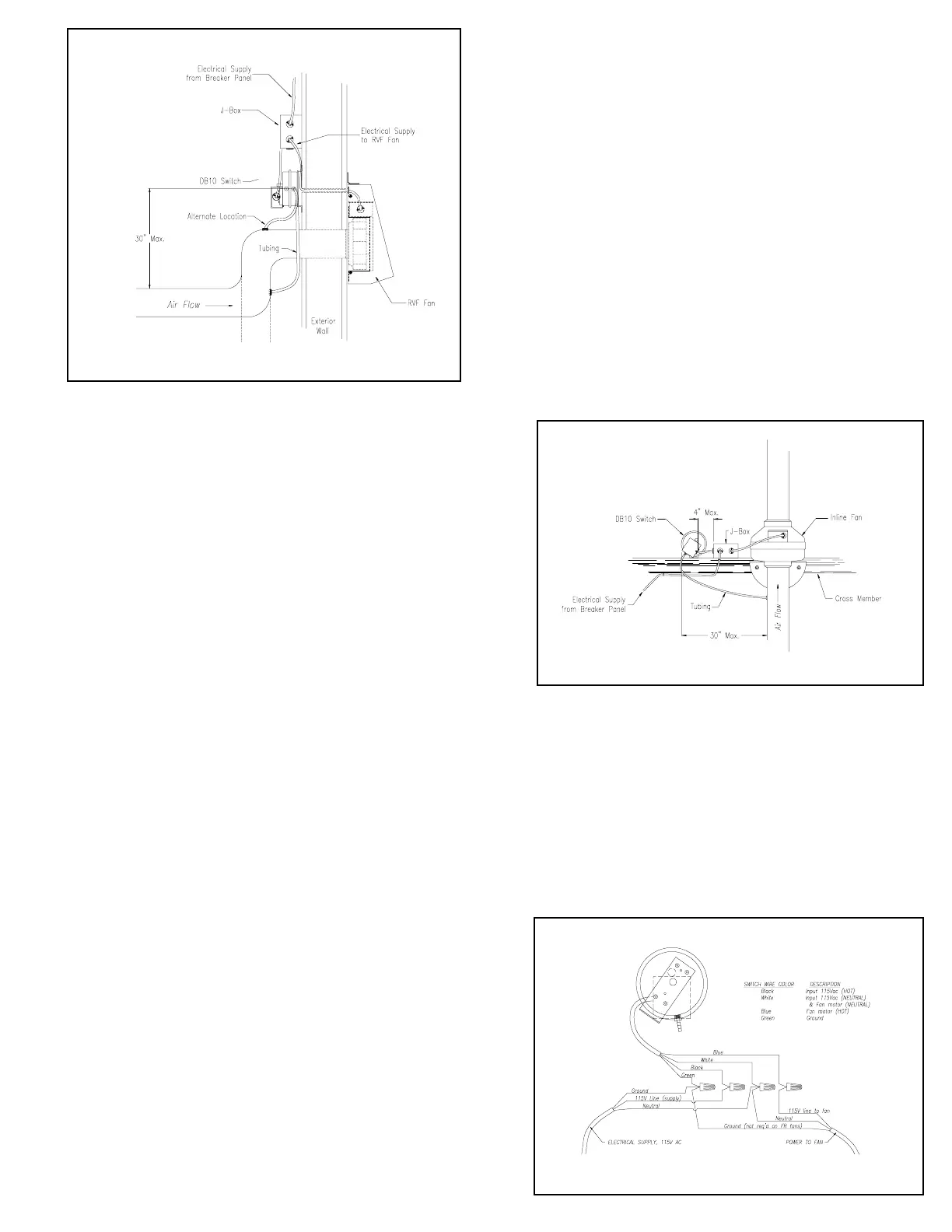

DB10 used with an RVF Series Fan

The RVF Series fans create very little resistance against the dryer

fan air flow when the RVF fan is not operating. A minimum

amount of pressure (approximately 0.05” - 0.07”) is required in

order to trigger the switch. For installations where there is a long

horizontal duct run prior to terminating at the fan, it may be

necessary to insert one or two elbows. The elbow(s) increase the

static pressure on the upstream side of the elbow. As illustrated,

the duct pressure tap should then be installed in the upstream side

of the first elbow. The dotted lines show an alternate location for

the pressure tap for systems with one elbow added. As an

alternative to inserting an elbow near the fan, the switch and

pressure tap may be located upstream of an existing elbow (as

shown on Page 2) or may be installed closer to the dryer.

Additional Installation Notes:

DB10 used with an Inline Fan

Unlike the RVF Series, the FR and FX Series fans create enough

resistance to the dryer fan flow to trigger the pressure switch. When

using the switch with an inline fan, the switch and pressure tap

may be installed near the fan or at any point along the duct between

the dryer and the fan. One advantage to locating the switch and

pressure tap near the fan are proximity to one another for servicing,

maintenance, troublshooting, etc.

Loading...

Loading...