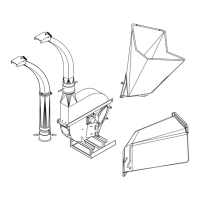

Why is my Farmi Forest Corporation Chipper making a strange noise?

- Bbrian57Aug 2, 2025

A strange noise from your Farmi Forest Corporation Chipper could be due to several reasons: * The bearings may need greasing. * The bearings may need to be replaced. * Loose bolts or fasteners may need tightening. * The clearance between the knives and anvils may need adjustment.