Do you have a question about the Farmi Forest Corporation VALBY CH 260 and is the answer not in the manual?

| Brand | Farmi Forest Corporation |

|---|---|

| Model | VALBY CH 260 |

| Category | Chipper |

| Language | English |

Explains safety terms and hazard symbols used in the manual.

Specific safety precautions related to the rotating knives.

Safety for hydraulic feeder and feed chute operation.

Safety guidelines for the hydraulic unit.

Safety precautions for using a separate hydraulic motor.

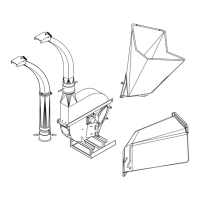

Identifies and illustrates the key parts of the chipper.

Lists technical specifications like output, power, and weight.

Procedures for assembling and attaching the chipper.

Guidance on adjusting the PTO shaft length for proper fitment.

Instructions for fitting optional screens or breakers.

Pre-operation checks to ensure safety and functionality.

Steps for safely starting the chipper.

How to properly shut down a tractor-powered chipper.

How to properly shut down a chipper powered by a hydraulic motor.

Instructions for feeding material and the chipping process.

How to adjust the discharge pipe and lid for chip direction.

Lubrication points and intervals for the bearings.

Lubrication points and intervals for the PTO shaft.

Regular checks to ensure the chipper is in good working order.

Steps to access the internal components by opening the upper chamber.

How to detach the knives from their mounting brackets.

Methods and guidelines for sharpening the chipper knives.

Instructions for detaching the vertical and horizontal anvils.

Guidance on sharpening the anvils to maintain their shape.

Procedures for refitting knives and anvils after maintenance.

How to set and verify the critical clearance between knives and anvils.

Method for adjusting chip size by moving knife brackets.

Loading...

Loading...