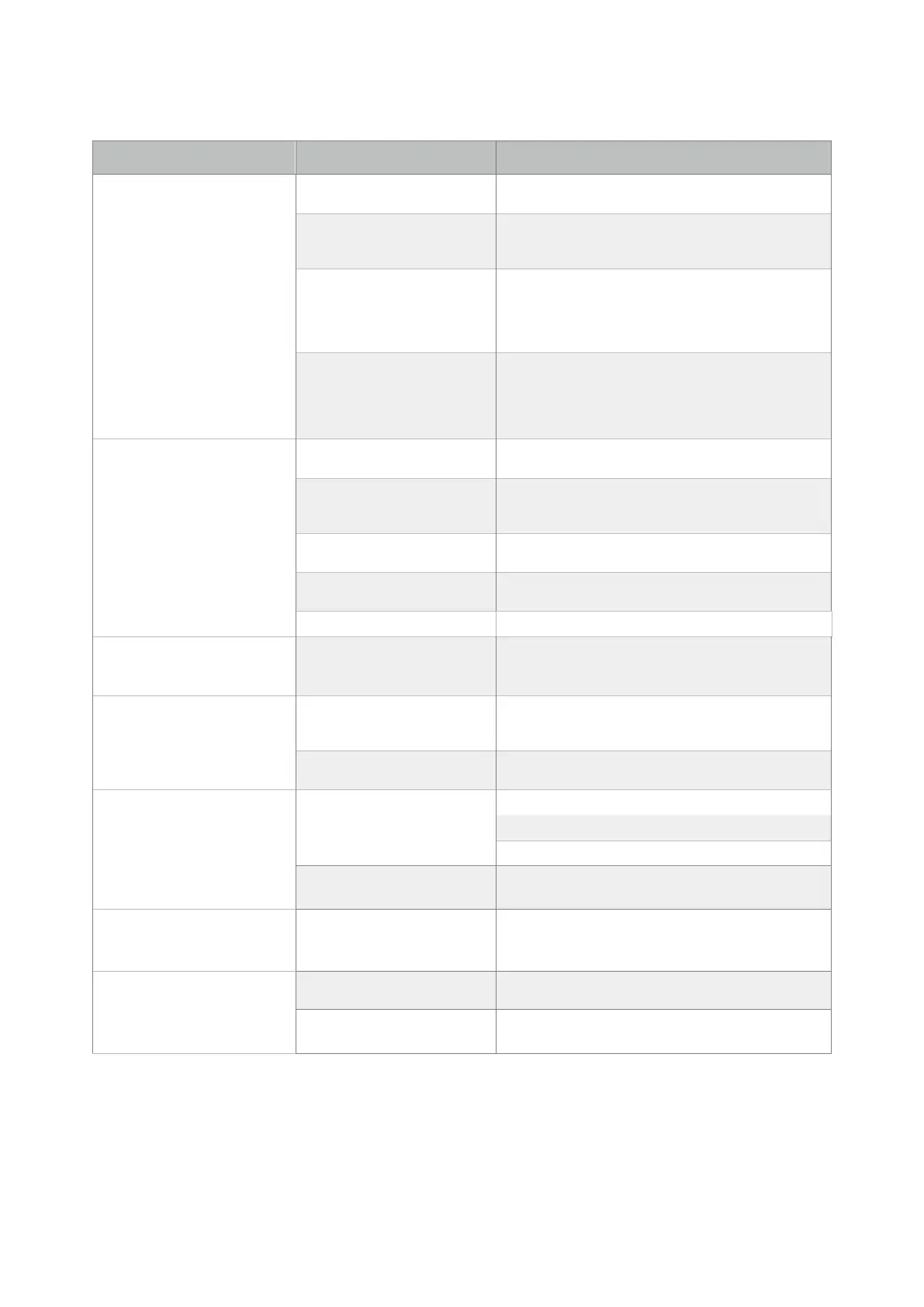

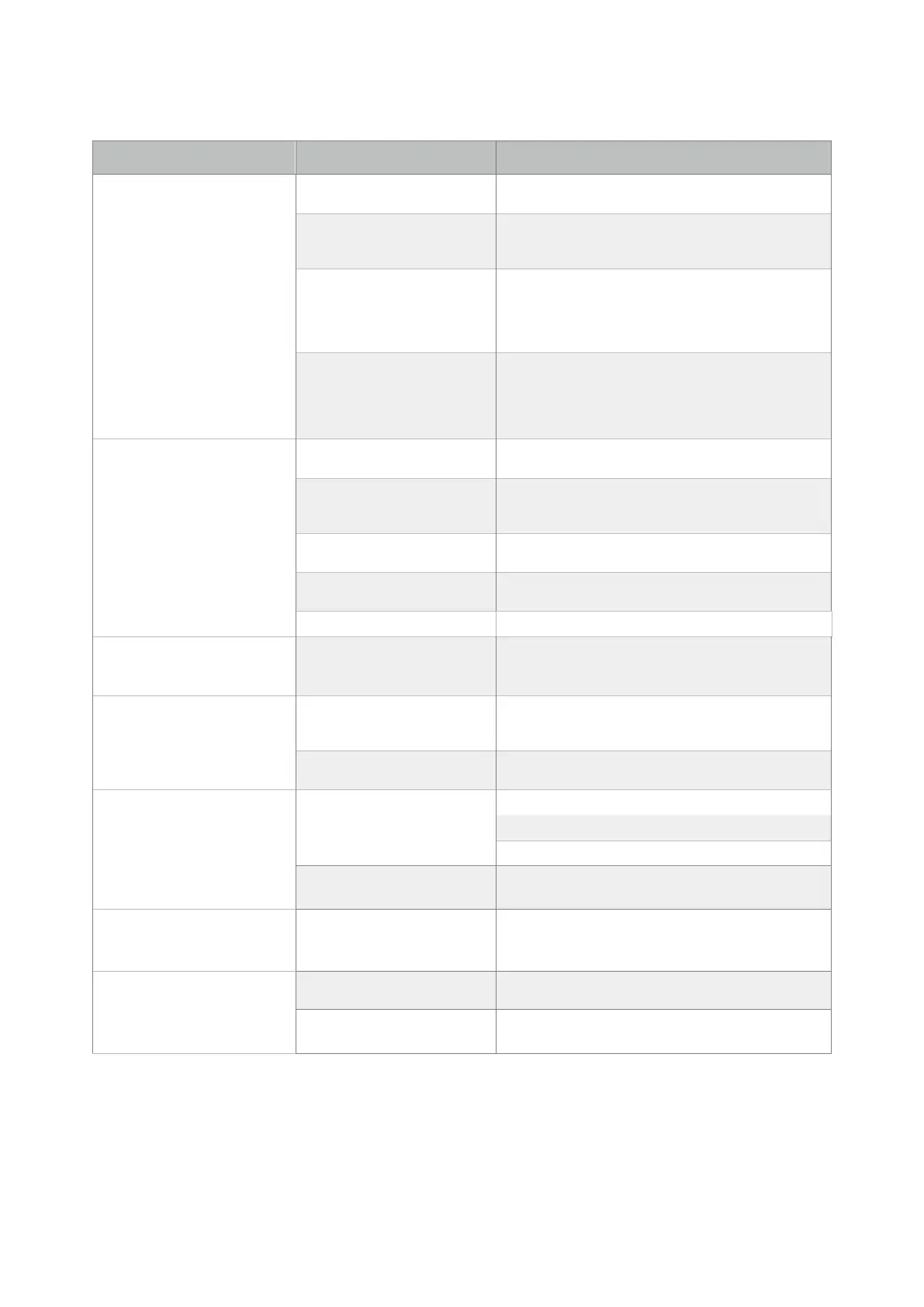

One or more

coulters do not

seed.

The slide cover is closed.

Bring the slide cover of the hoppers belonging to the

corresponding coulters.

The hopper inlet is clogged by

a foreign matter (such as stem,

dirt, sack rope, bag)

Remove the object that cause clogging on the box side.

Clogging in the telescopic pipe

or seed pipe

Check the pipe. If clogging exists, remove the cause of

clogging and discharge the seed accumulated inside

the pipe. Clogging mainly occurs at the end of the seed

pipe.

Stacking of seed at the center

or one side of the box

The seed inside the box tends to accumulate on one side in

sloping land and at the center of the box in cultivations

carried out in the fields with disturbed surface. In this case

distribute the seed inside the box to all the hoppers evenly

and fill the seed.

The seeds are not

covered. The seeds

remain uncovered.

The seeding depth is not

sufficient

Increase the seeding depth.

The harrow pressure is not

sufficient

Increase the harrow pressure to an appropriate level

by changing the positions of the harrow pressure

adjustment plate and harrow spring.

Take the harrow block one step down. Replace the bars

when the block is at the bottom position.

Incorrect pressure wheel height

adjustment

Ensure that the pressure wheels are in contact with the

soil.

Make seeding at a speed of 6 km/h and above.

Seed flow does not stop

when the grain drill stops.

Incorrect throttle adjustment

The clearance between the throttle and gear is too high.

Narrow the throttles according to the size of the seed

planted.

Seed is broken and

damaged.

Incorrect throttle adjustment

The clearance between the throttle and gear is too low.

Seed is jammed between the throttle and gear. Extend the

throttles according to the size of the seed planted.

The mixer is not suitable for the

type of seed planted.

Seed and/or fertilizer

accumulate at the

center of the box

during operation.

Operation with high vibration

Reduce the operating speed.

Make the seed bed thinner/flatter.

Check the tire air pressures.

Decrease in the amount

of seed/fertilizer

The seed/fertilizer level drops below the 1/5 of the

box volume. Add seed/fertilizer.

Accumulation of

seed/fertilizer on one

side of the box

Working on a laterally

sloped field

Change the working direction to be perpendicular to

the slope rather than parallel.

The seed/fertilizer

gauge malfunctions.

The float is not switched to

working position

Switch the float to working position after each filling.

Shift in float/pointer

direction

Loading...

Loading...