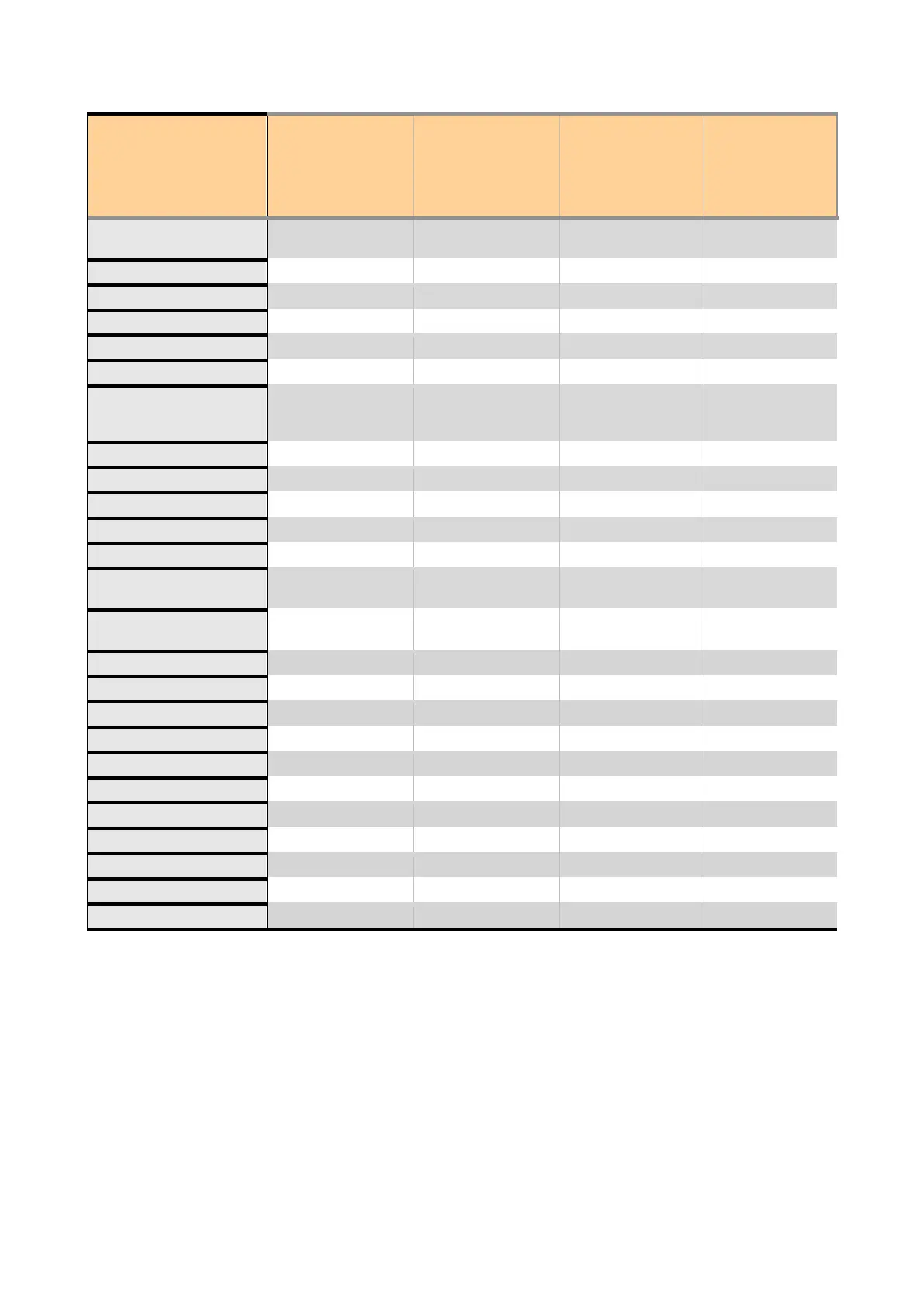

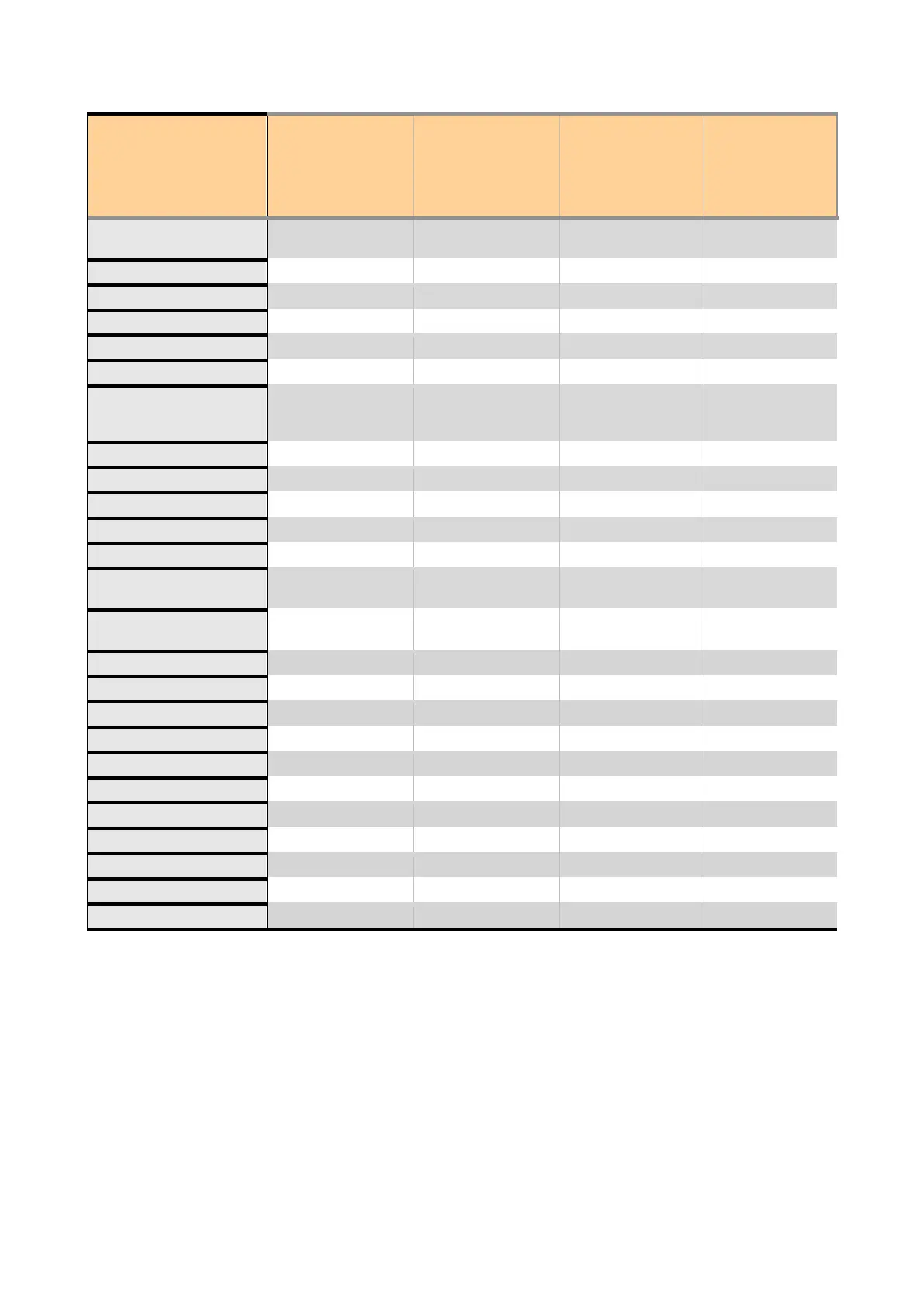

4 main maintenance processes are implemented in the periodic maintenance of your grain drill, which are check,

lubrication, check/replacement and replacement. The periods of such maintenance operations are listed in the

table. The specified maintenance operation is implemented when any of the conditions stated in the periods (in terms of

time or work area) occur.

Abbreviations and their meanings:

C: (check) the part or element is visually and manually checked. The part is cleaned. Loosening or gaps are removed.

Lubrication, completion and replacement is carried out, if necessary.

L: (lubrication) Lubricate the specified area with appropriate lubrication (grease, machine oil, etc.).

C/ R: (check/replacement) Check the relevant part, component or mechanism. Replace the worn, fatigued or

damaged parts. Complete the deficiencies.

R: (replacement) Replace the specified part or element whether it is damaged or not.

Loading...

Loading...