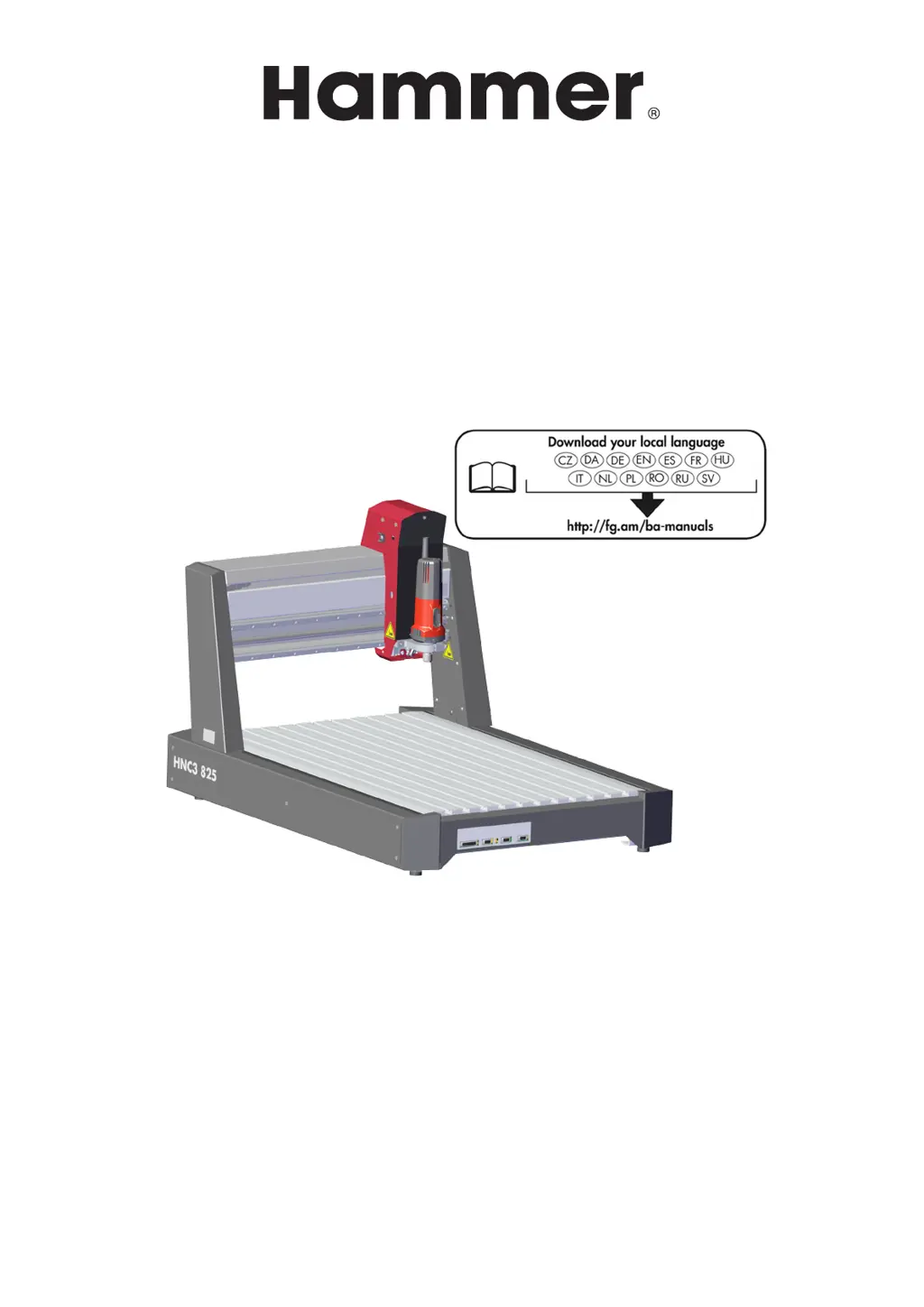

What to do if my Felder Hammer HNC3 825 does not start?

- UuleeAug 7, 2025

If your Felder Power Tool doesn't start, there are several potential reasons: 1. There may be an issue with the electrical connection. Check the connecting lead and fuses. 2. The main switch might be off. Ensure the main switch is in the "I" position. 3. The emergency stop button may have been pressed. Unlock the emergency stop. 4. The emergency stop might not be properly connected to the machine. Connect the emergency stop to the machine.