5 Mounting and installation instructions

Warning

Electric shock

Injury to people, damage to the machine and system.

Switch off the power supply before mounting or removing the module (risk of

malfunctions or damage).

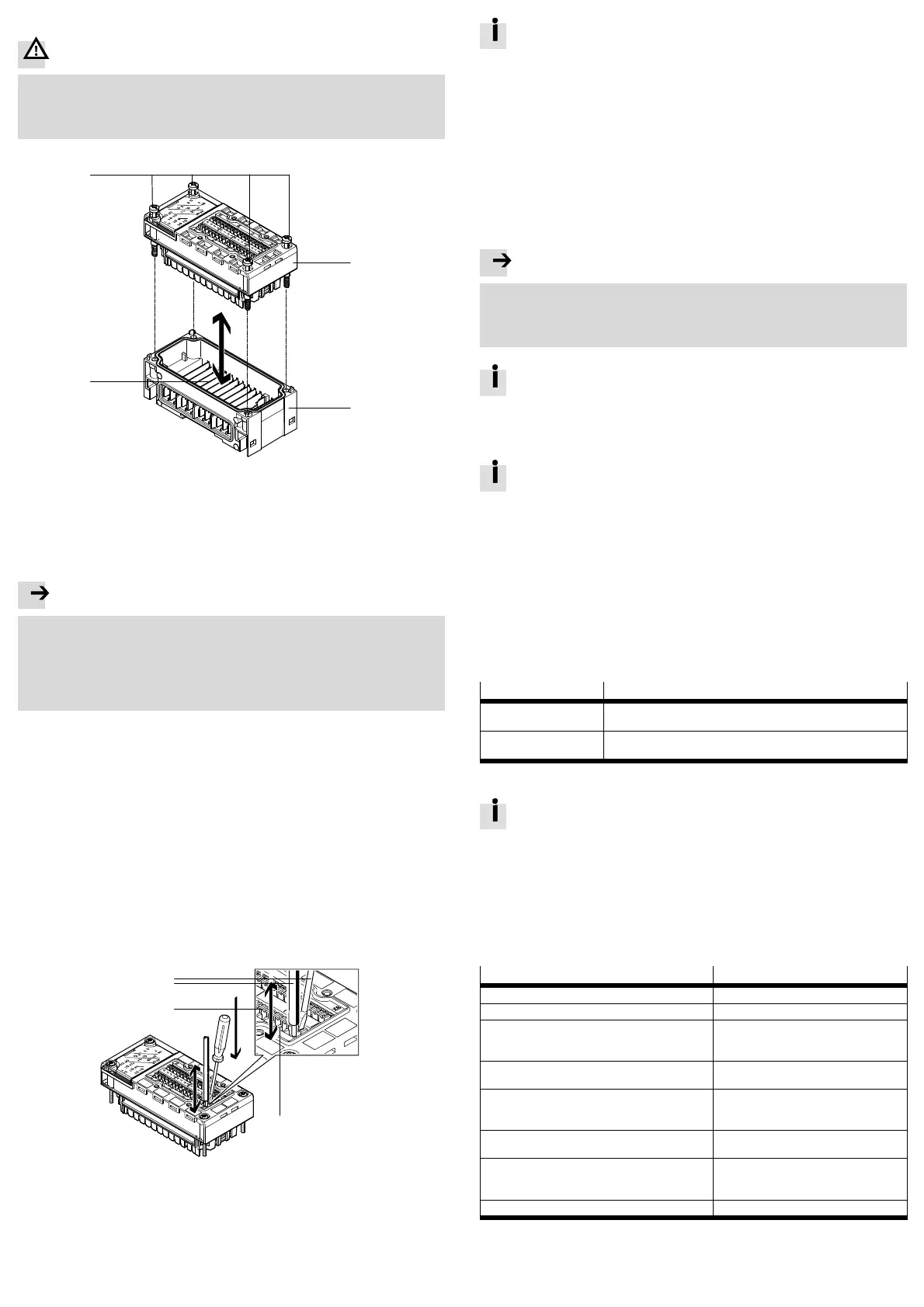

The module is mounted in an interlinking block of the CPX terminal.

1

2

3

4

1 Module

2 Interlinking block

3 Contact rails

4 Screws, tightening

torque:0.9...1.1 Nm

Fig. 4

5.1 Dismantling

Unscrew the screws and carefully remove the module.

Note

Material damage due to incorrect mounting

Select screws that are suitable for the material of the interlinking block:

– plastic: Thread-cutting tapping screws

– metal: Screws with metric thread.

When ordering a single module without a CPX terminal, both types of screws are

supplied.

5.2 Mounting

1. Check the seal and sealing surfaces.

2. Push the module carefully and without tilting as far as possible into the inter

linking block.

3. Insert the screws so that the existing threads are used.

4. Tighten the screws by hand in diagonally opposite sequence. Tightening torque:

0.9…1.1 Nm.

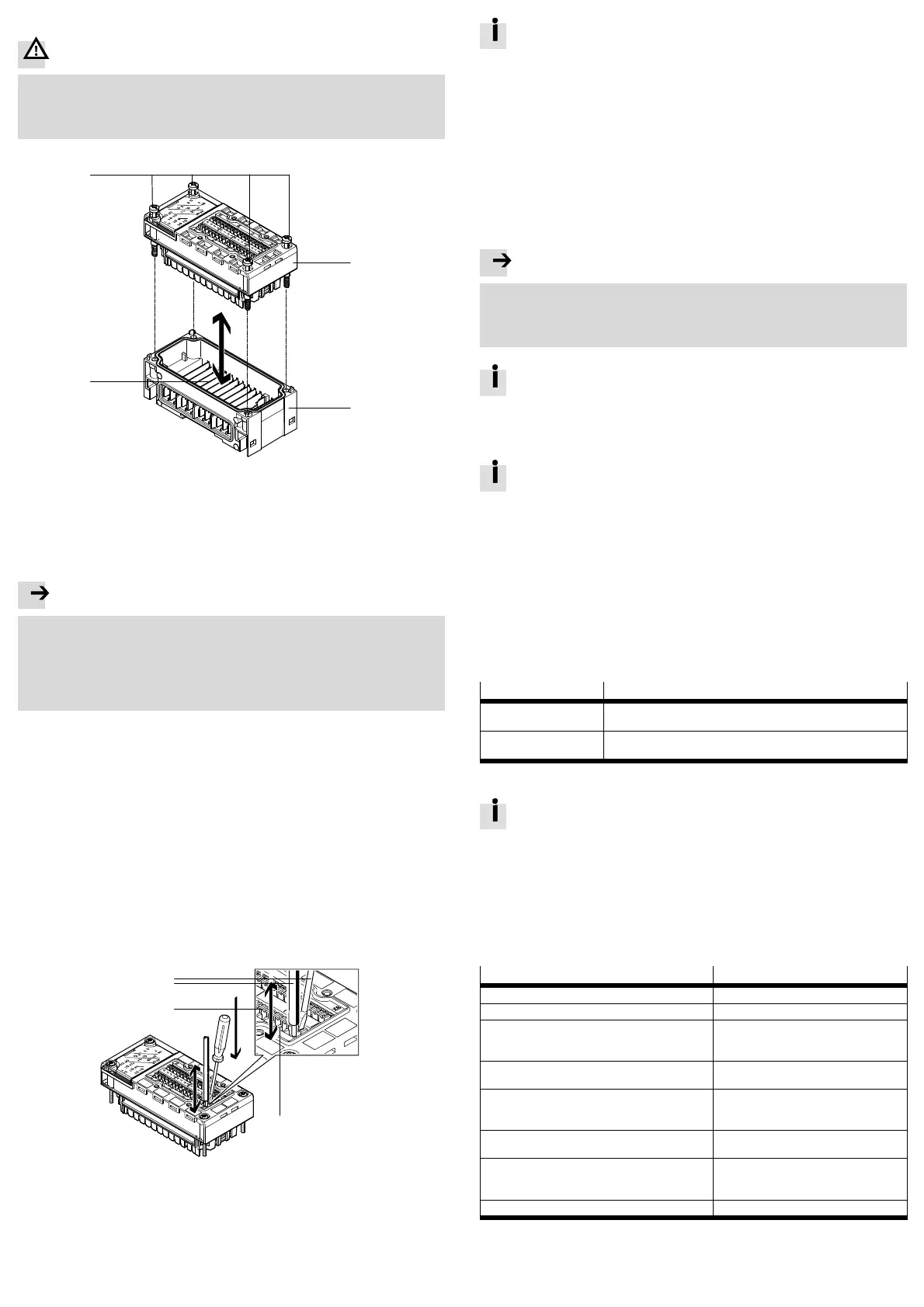

5.3 Electrical installation

Terminal specifications:

– conductor cross section: 0.13 … 1.5 mm

2

– stripped insulation: 5 … 6 mm.

1. To unlock the terminal depress the release mechanism with a screwdriver.

2. Insert or remove the conductor.

3. Remove the screwdriver from the release mechanism.

1

2

3

4

1 Screwdriver,

blade 2.5 × 0.4 mm

2 Conductor

3 Terminal release (inside)

4 Terminal opening for inserting the

conductors (outside)

5 Terminal

Fig. 5

To comply with protection class IP65/IP67, use the cover AK-8KL and the

VG-K-M9 fittings kit. Observe the relevant assembly instructions when

doing this.

6 Commissioning and configuration

6.1 Commissioning

1. Check the module and peripheral equipment.

2. Check the CPX terminal and its power supply.

3. Commission the entire system (è CPX system description, è description of the

bus node used, è description of the module).

6.2 Configuration

The Festo Maintenance Tool for CPX terminals (CPX-FMT) or the higher-order con

troller can be used for the configuration process.

Note

Malfunction due to faulty configuration

When using the higher-order controller for the configuration process, the config

uration options are not restricted to the operating mode-specific settings.

Only perform configuration settings that are described in the module description.

The configuration settings created in the CPX-FMT can be exported as a

configuration file for many common control systems (è CPX-FMT online

help).

6.3 Parameterisation

For information regarding parameterisation, module replacement and start

behaviour, please refer to the module description.

6.4 Operating modes

The module provides operating modes for:

– counting

– measuring

– position and speed determination

– pulse output

– motor operation.

7 Diagnostics

The following possibilities for diagnostics and error handling are available, de

pending on the parameterisation of the module:

Diagnostics option Description

LED display The LEDs directly display hardware faults, configuration errors, bus

errors, etc.

CPX diagnostic function The module reports specific malfunctions as error messages (error

numbers) to the CPX bus node or CPX-FEC/CPX-CEC.

Fig. 6

For details regarding diagnostics, please refer to the module description.

8 Maintenance, repair, disposal

The module does not contain any wearing parts.

Replace the module if it becomes defective.

If possible, send the defective module together with a description of the error

and application to Festo for analysis.

Dispose of electronic components using a certified waste disposal company.

9 Technical data

Type CPX-2ZE2DA

General technical data è description P.BE-CPX-2ZE2DA-…

Protection class in accordance with EN 60529 IP65/IP67

Protection against electric shock, protection against

direct and indirect contact in accordance with

IEC 60204-1

by means of PELV circuits

(Protected Extra-Low Voltage)

Operating voltage supply

– electronics/sensors (U

EL/SEN

) 18 … 30 V DC

Intrinsic current consumption at 24 V

– from operating voltage supply for electronics/

sensors (U

EL/SEN

)

max. 370 mA

Continuous output current

– continuous output current of the digital output DO max. 5 A (parameterisable)

Continuous nominal current

– encoder/sensor supply 24 V DC

– encoder supply 5 V DC

max. 1 A

max. 1 A

Parallel connection of outputs to increase power is not permissible

Fig. 7

Loading...

Loading...