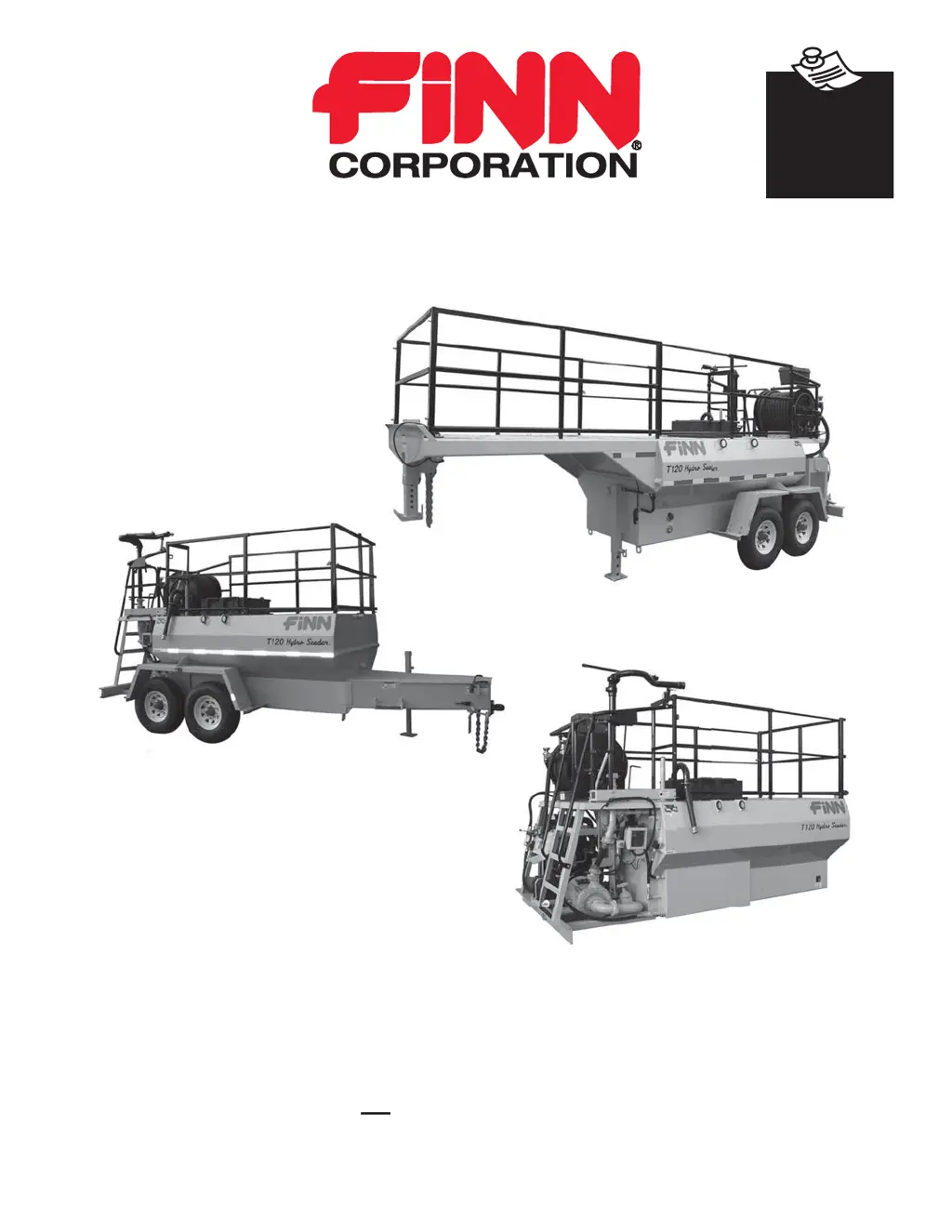

How to fix leaks in Finn T120-II HydroSeeder Seeders?

- Ssheri91Aug 2, 2025

To address leaks in your Finn Seeders, start by tightening any loose bolts uniformly to 25 lb–ft (34 N•m). Replace any cracked, pinched, or torn rubber seals, and always grease seals before clamping shut. Also, replace any worn or missing gaskets and O-rings, using grease when replacing the O-rings. Ensure you follow the lubrication schedule and replace the pump seal, servicing the automatic pressure lubricator daily if it is not serviced. If the swivels are leaking, consider rebuilding them with a repair kit (part number 006969, qty. 2 required). The causes of the leaks may be lack of lubrication, bolts that aren't tightened, cracked rubber seal, pressure lubricator not serviced, bad O-ring, worn or no gasket.