This expansion tank and the entire system must be checked annually by a qualified professional.

Visually examine the tank and its connection to the system piping looking for any signs of water leakage or corrosion on the

exterior of the tank or the connection.

If this expansion tank shows any visible signs of leaking, corrosion or rusting, the tank must be replaced

immediately to avoid personal injury or property damage. Do not adjust the tank air pressure if there

are any signs of corrosion on the tank. Failure to follow these instructions may result in serious injury or death and or

property damage.

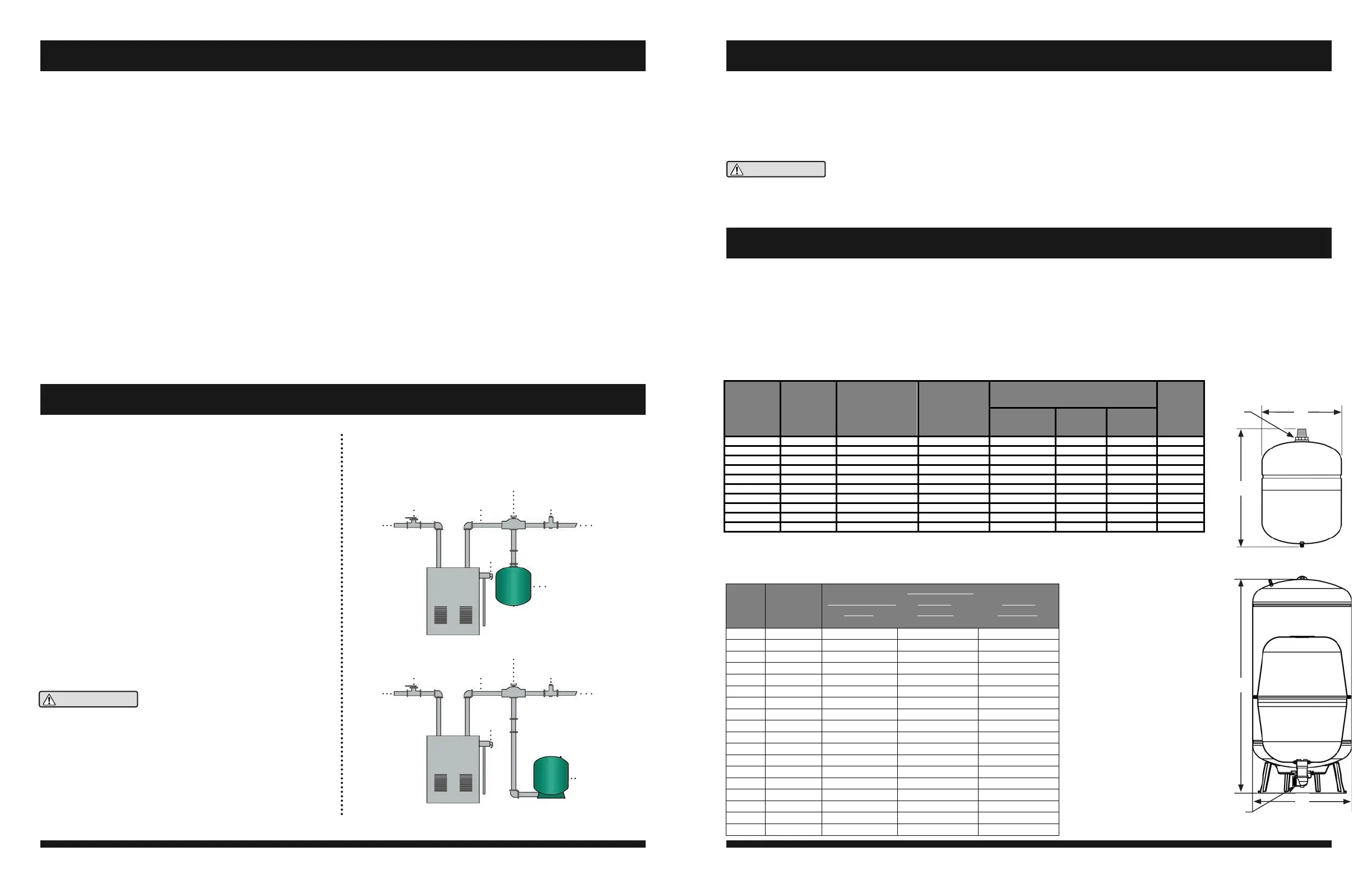

D I ME N S I ON S & C A P A C I T I E S

Rev. 6.18

Visually inspect the product for any signs of damage that may have occurred during transportation. If the tank is dented, bent

or scratched, return the product to the original purchase point for replacement.

This expansion tank is shipped from the factory with a pre-charge of 12 psi. Any adjustments to the factory pre-charge

must be done prior to initial tank installation and with 0 psi pressure on the system. DO NOT ADJUST THE PRE-CHARGE

OF THE EXPANSION TANK WITH THE SYSTEM UNDER PRESSURE!

The expansion tank should be pre-charged to match the boiler fill valve setting.

failure to properly adjust the pre-charge will shorten the life expectancy of the product.

Remove the protective cap from the air valve.

Check the tank pre-charge pressure using a standard tire pressure gauge.

If required add air to the tank using a manual bicycle tire pump until the proper pre-charge pressure is reached.

Replace the protective cap on the air valve.

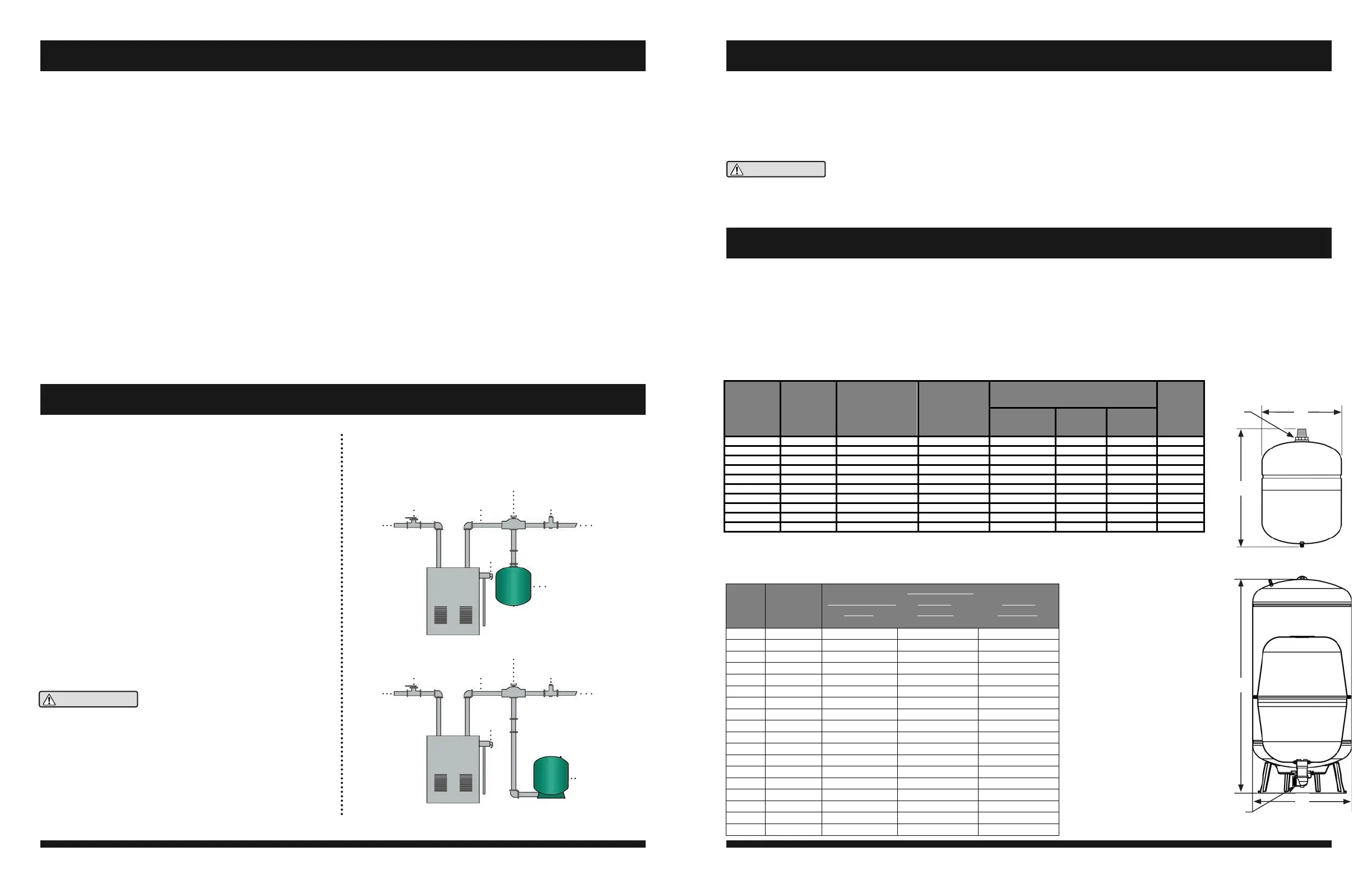

TYPICAL INSTALLATIONS

P.O.

Inlet

To

System

In Line

Expansion

Pressure

Relief

Valve

Auto Fill

Valve

Air

Separator

Flow

Check

Air

Vent

P.O.

Vertical

Floor

Mount

Expansion

Tank

Inlet

To

System

Pressure

Relief

Valve

Auto Fill

Valve

Air

Separator

Flow

Check

Air

Vent

S XHT

SERIES

HTX

SERIES

MATERIALS OF CONSTRUCTION

Tank: 16-gauge, cold rolled steel

Finish: Appliance quality paint for corrosion resistance

Water Chamber SXHT: Top diaphragm is 100 % butyl rubber, lower

water chamber is copolymer polypropylene

Diaphragm Material HTX: 100% butyl rubber

Connection: Welded steel

Testing: High pressure, seam weld, helium, final pre-charge check

Air Valve: Brass valve with o-ring seal

Warranty: 5 years

Boiler

Output

1000’s

BTUH

Copper

Baseboard

& Radiant

Type of Radiation

Convectors & Unit Cast Iron Cast Iron

Heaters Radiators Baseboard

25 HTX 15 HTX 15 HTX 15 HTX 15

50 HTX 15 HTX 30 HTX 30 HTX 30

75 HTX 30 HTX 30 HTX 60 HTX 60

100 HTX 30 HTX 30 HTX 60 HTX 60

125 HTX 30 HTX 60 HTX 60 HTX 60

150 HTX 30 HTX 60 HTX 90 HTX 90

175 HTX 60 HTX 60 HTX 90 HTX 90

200 HTX 60 HTX 60 HTX 90 HTX 90

250 SXHT 30 SXHT 30 SXHT 40 SXHT 30

300 SXHT 30 SXHT 40 SXHT 40 SXHT 30

350 SXHT 30 SXHT 40 SXHT 60 SXHT 40

400 SXHT 30 SXHT 60 SXHT 90 SXHT 40

500 SXHT 40 SXHT 60 SXHT 90 SXHT 40

600 SXHT 40 SXHT 90 SXHT 90 SXHT 60

700 SXHT 60 SXHT 90 SXHT 90 SXHT 60

800 SXHT 60 SXHT 110 SXHT 110 SXHT 90

900 SXHT 60 SXHT 110 SXHT 110 SXHT 90

1000 SXHT 90 SXHT 110 SXHT 110 SXHT 90

1. Drain boiler system or isolate the area where expansion

tank will be installed.

2. Install expansion tank on supply side of the boiler, on

the suction side of the circulator. Adequate thread sealant

(pipe dope) must be added to ensure a leak free

installation.

3. Connect system piping to discharge opening of the tank

using a tee, air scoop, or other suitable tapping in the

system.

4. Pressurize the system and check for leaks.

5. Restart the boiler system.

The tank (HTX) is designed to be supported by system piping. Make

sure that there is adequate means of supporting the system piping

and, if necessary, add strapping, brackets, or pipe hangars.

DO NOT INSTALL THIS EXPANSION TANK IN THE HORIZONTAL

POSITION.

Maximum working pressure 100 psig. Maximum working temperature, 240 F. Tank pre-charge 12 psig.

Note: HTX series expansion tanks ARE NOT suitable for potable water and are only to be used on closed systems.

Model

Capacity

(gallons)

Acceptance

Volume

(@12/30 PSIG)

Max.

Acceptance

Volume

Dimensions

(inches)

Weight

(lbs)

Connection

Size

(C)

Diameter

(B)

Height

(A)

HTX 15 2.1 .85 1.0 ½” MPT 8 11.6 6

HTX 30 4.8 1.9 2.4 ½” MPT 11 14.5 10

HTX 60 6.0 2.9 3.6 ½” MPT 11.4 17.6 11

HTX 90 15.0 6.0 6.0 ¾” MPT 16 20.8 28

SXHT 30 15.0 6.0 6.0 1” FPT 16 21.7 32

SXHT 40 20.0 8.0 8.0 1” FPT 16 28.8 39

SXHT 60 33.0 13.3 13.3 1” FPT 16 42.8 57

SXHT 90 44.0 17.7 17.7 1 ¼” FPT 21 36.2 72

SXHT 110 62.0 24.9 24.9 1 ¼” FPT 21 47.9 112

SXHT 160 81.0 32.6 32.6 1 ¼” FPT 21 62.0 123

QUICK SIZING CHART

HTX SERIESHTX SERIES

A

B

C

SXHT SERIES

A

B

C

Loading...

Loading...