9

SPLASH GUARD ASSEMBLY

The two splash guards have to be assembled onto the brush base

group. Insert the metal strips inside the suitable slots present on the

rubber. Place the round hole at the flat extremity of the strip onto

the screw placed in the front part of the brush base group. Secure the

strips through the nut blocking it.

Screw down the knobs in the rear part of the cover in the free

extremity of the metal strips. The operation has to be carried out for

both splash guards.

With the brush assembled, the splash guard must slightly touch the

floor.

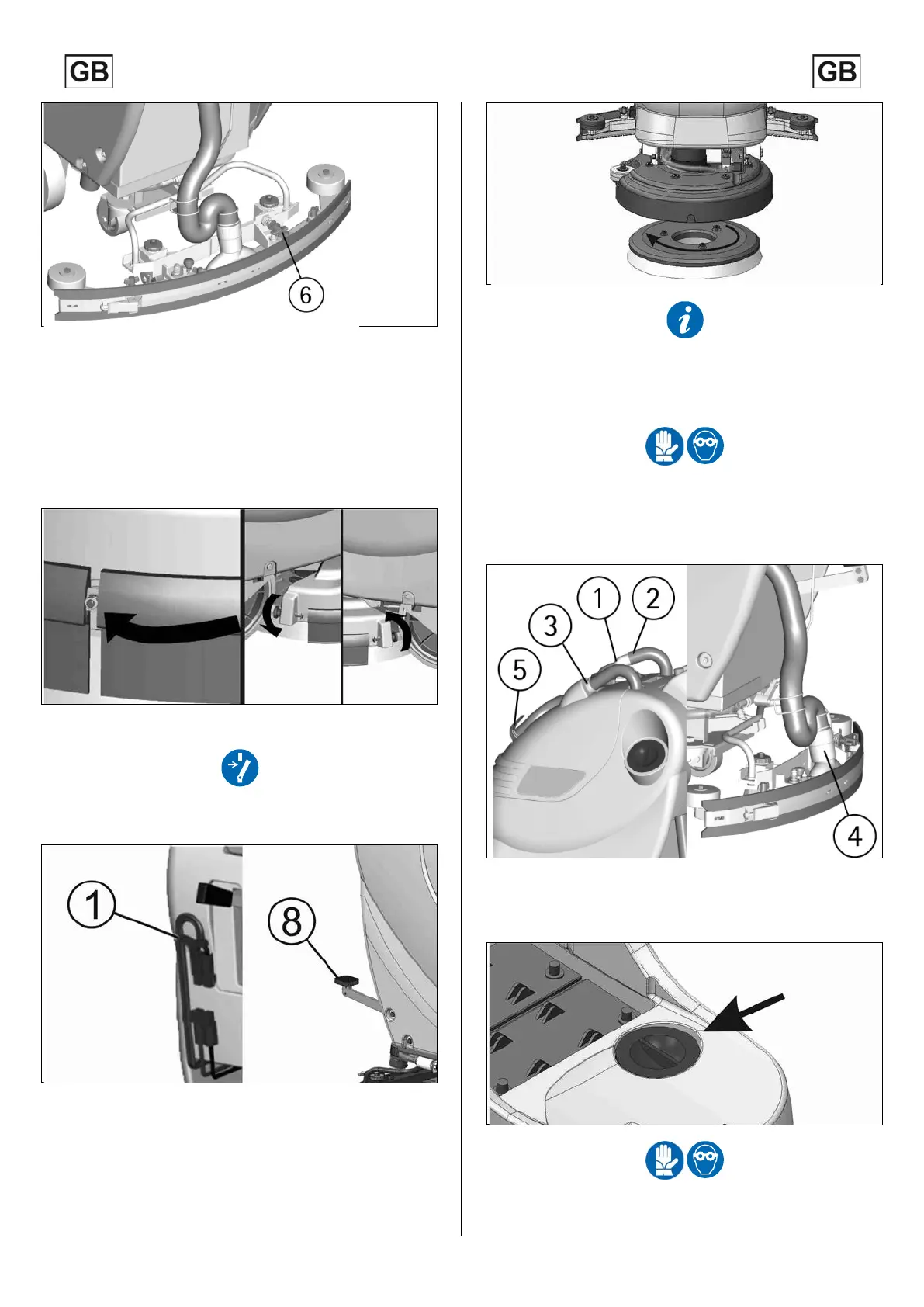

BRUSH ASSEMBLY

1. Take off the electric supply to the brush motor unplugging the

batteries connector (1).

2. Acting upon the pedal (8) lift the brush base group.

3. With the brush base group in lifted position, insert the brush

into its plate seat underneath the brush base turning it until the

three metal buttons are properly seated in their slots; rotate

energically the brush to push the button towards the coupling

spring until it gets blocked.

The figure shows the rotating sense for the brush coupling.

Use only brushes supplied with the machine or the ones indicated in

the paragraph “RECOMMENDED BRUSHES”. The use of other brushes

can compromise the security.

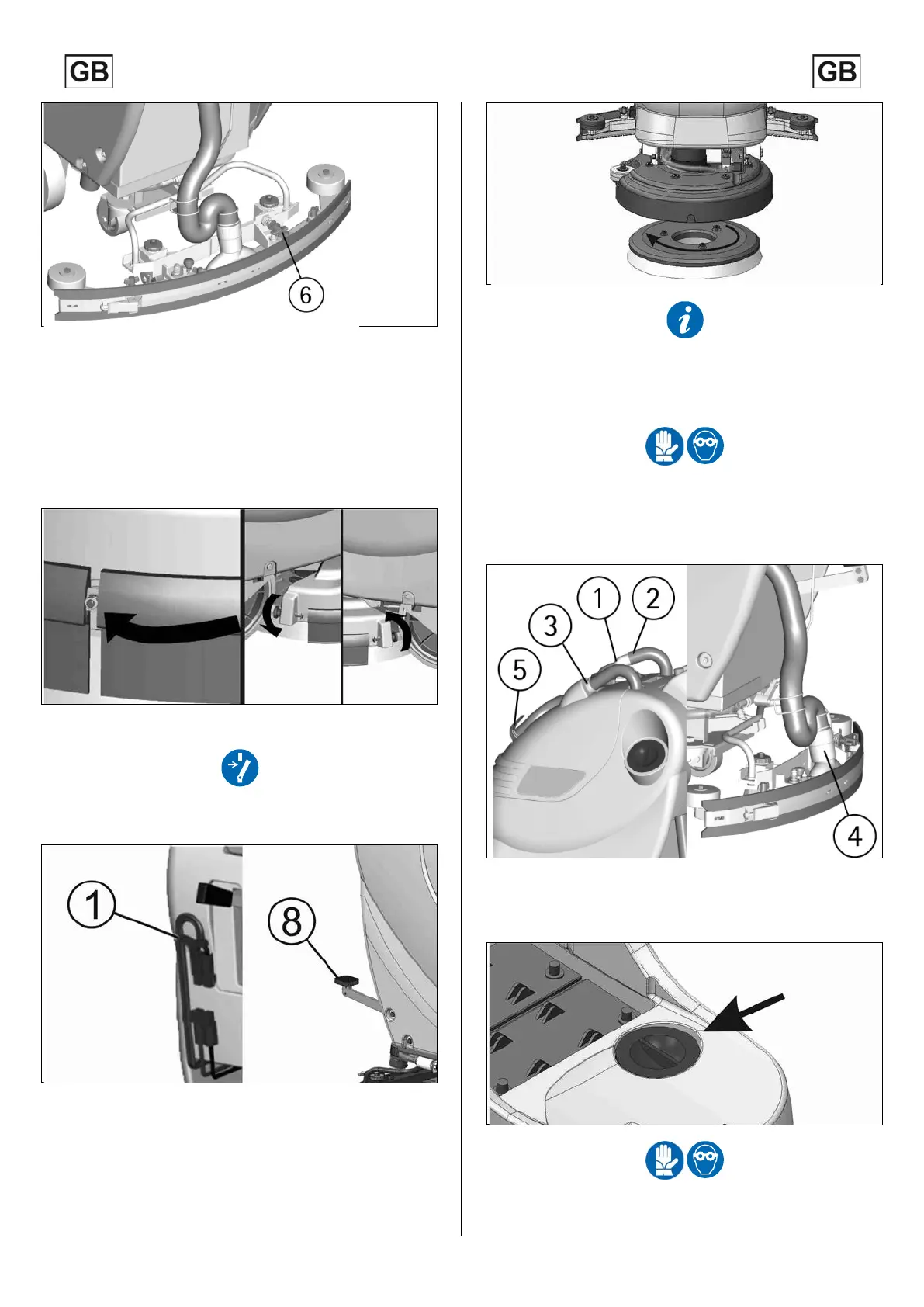

RECOVERY TANK

Check that the cover of the suction filter (1) is correctly secured, after

rotating the levers and that the suction motor hose (2) is correctly

connected.

Verify also that the squeegee hose is correctly inserted into the seats

(3 and 4) and that the exhaust hose plug (5) placed in the front part

of the machine, is closed.

DETERGENT SOLUTION TANK

The solution tank is provided with an inspection opening. This permits

to clean the exit point of the detergent solution.

Be sure that the cap is well tightened after the cleaning.

The capacity of the detergent solution tank is indicated in the

technical data.

Open the screw plug (1) placed in the rear left part of the machine

and fill the detergent solution tank with clean water at a maximum

Loading...

Loading...