415B

NOTE!

The unit must have

been

operated

for

one hour

before testing

to

the

following

requirements.

The

cover must be in place during the ripple

test.

NOTE!

Meter readings

will vary with

contact

resistance.

Make comparative readings

with

load

on

Front

and rear

output

terminals.

4-23.

OUTPUT AT ZERO VOLTS. This test checks for

imbalance

in the voltage control circuit.

a. Set the controls of the Model

415B

as follows:

POWER

ON

HIGH

VOLTAGE STDBY/RESET

POLARITY Negative

OUTPUT

VOLTAGE All zeros

dials

b. Connect the Model 885A across the

OUTPUT

con-

nector.

c. Set the HIGH VOLTAGE switch to

ON. The Model

885A at null should indicate

no more than 50

milli-

volts for

both polarities.

4-24.

LINE REGULATION. This test determines

whether the

deviation in output is

within specified limits

for

a change from low to high

line

voltage.

a. Set the

controls

of the Model 41

5B

as

follows:

POWER

ON

HIGH

VOLTAGE

STDBY/RESET

POLARITY

Positive

OUTPUT

VOLTAGE

Second dial to

500;

dials

all others

to zero

b.

Connect the

Mode!

885A

across the front

panel OUT-

PUT connector.

c.

Adjust

the autotransformer

for 103

volts output.

d. Set the

HIGH

VOLTAGE switch

to ON. Adjust the

Model

885A for

a null

indication.

e. Connect

a 16.7K ohm

resistor

across the rear

panel

OUTPUT connector.

The voltage

change indicated

by

the Model

885A shall be

less than

2.0 millivolts.

a.

Set the controls

of the

Model

415B

as follows:

NOTE!

POWER

ON

POLARITY Positive

OUTPUT VOLTAGE Second dial to

500;

dials all others to zero.

b. Adjust the

autotransformer for

103 volts output.

Adjust the Model

885A for

a

null indication.

c. Increase the

line voltage to 127 volts.

The output

voltage

change indicated

by

the Model 885A

shall

be less than

3

millivolts

(6

ppm).

d. Set the HIGH

VOLTAGE switch

to

STDBY/RESET

and disconnect

the Model 885A from

the OUTPUT

connector.

Meter

readings

will vary

with

contact

resistance.

Make

comparative

readings

with

load

on

front

and

back output

terminals.

f.

Disconnect

the

load resistor

and

see

the

POLARITY

switch

to negative.

g.

Repeat

the measurements

of

steps d and

e,

4-26.

RIPPLE.

This test

determines

whether

the-

residual ac

component superimposed

on the dc output

is within specified

limits. Ripple

is

usually higher

with negative

polarity output.

Proceed

as follows:

a. Set

the controls of the Model 41

5B

as follows:

e. Set the autotransformer output

to 103 volts. Set

the first

OUTPUT

VOLTAGE dial

to

2500,

the

second dial to 500 and all others to zero.

f. Connect the

output terminals of the Model

80F-5

voltage

divider to the input of the Model

885A

and

connect the divider input

across the Model

415B

OUTPUT connector.

g.

Set the

HIGH VOLTAGE

switch to ON and adjust

the

Model 885A

for null

indication.

h. Increase the line

voltage

to 127 volts. The voltage

change indicated

by the

Model

885A

should be

no

more than 1. 8 millivolts

(6

ppm) at the 10:1

divider

output.

4-25.

LOAD

REGULATION. This test determines

whether

the output

deviation is within

specified

limits

for a

load

change from

no load to full load. Before

perform-

ing

the

Load Regulation

Test,

verify current,

limit trip

point

is 30

milliamps

or

greater.

If

it is

not, adjust

it according

to

the

procedure

in paragraph

4-33.

POWER

HIGH VOLTAGE

POLARITY

OUTPUT VOLTAGE

dials

ON

STDBY/RESET

Negative

Second

dial to

500;

all others to

zero

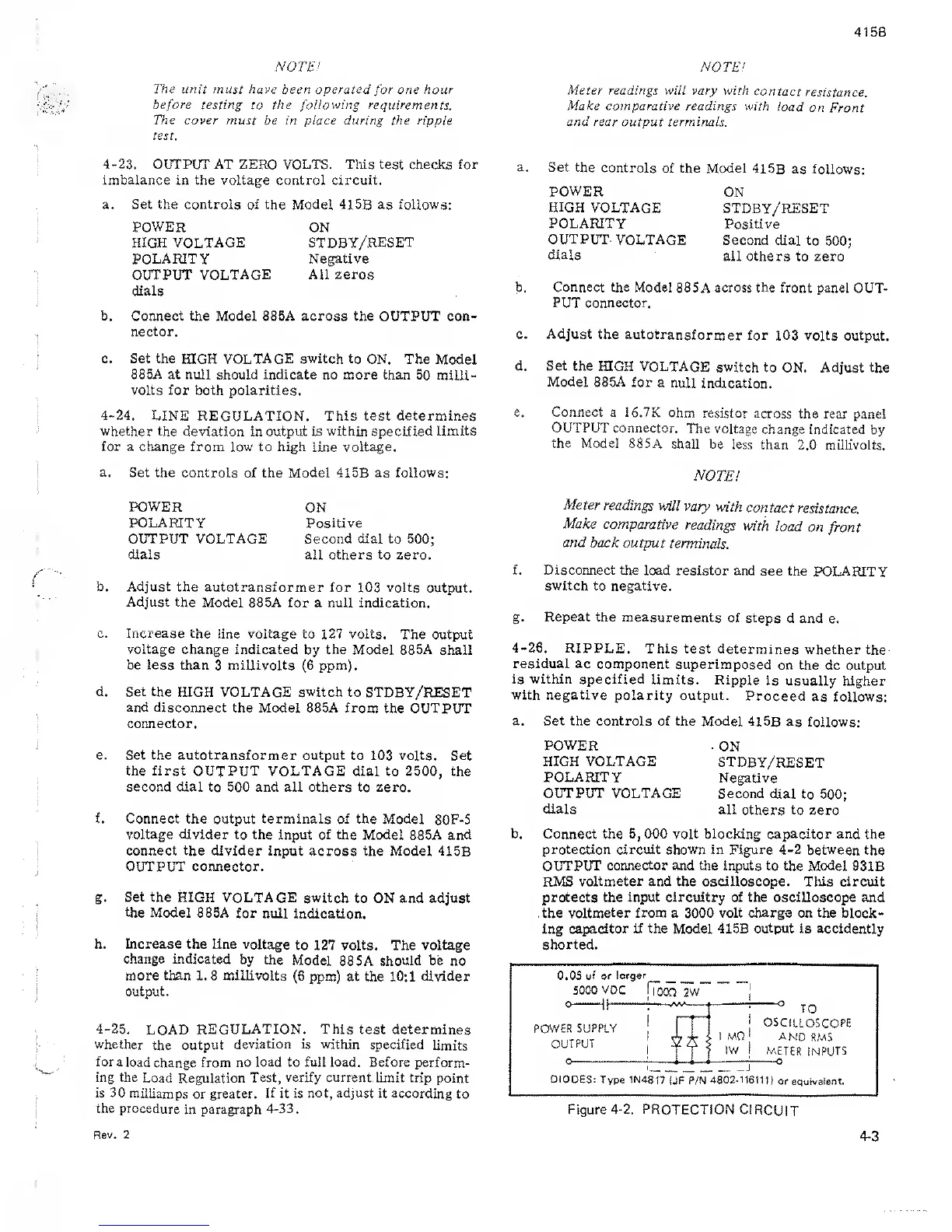

b. Connect the 5,000

volt

blocking capacitor and the

protection

circuit shown

in Figure

4-2

between the

OUTPUT

connector

and the inputs to the Model

93 IB

RMS

voltmeter and the oscilloscope.

This

circuit

protects the

input circuitry of the oscilloscope

and

the

voltmeter from a 3000 volt

charge

on the block-

ing

capacitor if the

Model 415B

output

is accidently

shorted.

0.05

uf or

larger

5000

VDC

ffoCQ

2W

« it

'

0

1 |

w

°

TO

POWER SUPPLY

1

1 I

I

OSCILLOSCOPE

OUTPUT

0

!

tfl

1 MQ

IV/

j

AND

RMS

METER

INPUTS

DIODES:

Type 1N4817

(JF P/N

4802-116111)

or equivalent.

Figure

4-2.

PROTECTION

CIRCUIT

Rev. 2

4-3

Loading...

Loading...