41 5B

c.

Set the HIGH VOLTAGE switch to

ON. The ripple

indication shall be less than 1.0

millivolt peak-to-

peak and

less than

100

microvolts

RMS.

d. Adjust the line voltage from 103

to 127 volts and

observe the ripple indication.

Ripple shall be

within the limits specified in

step

c.

e.

Set the first OUTPUT

VOLTAGE dial

to

2500,

the

second dial to 500 and other dials

to zero.

f.

Vary the output

of

the autotransformer between

103

and 127 volts and

observe the ripple indication.

Ripple shall be

within

the limits

specified in step c.

4-27.

OUTPUT VOLTAGE ACCURACY.

To

determine

the accuracy of output

at

each

OUTPUT VOLTAGE

switch setting, perform the procedures

of paragraphs

4-30

and

4-31,

deleting the adjustments.

4-28.

OVERCURRENT CHECK.

To check the trip

point of the overcurrent circuit, perform

the procedures

of paragraph

4-33,

deleting the adjustments.

4-29.

CALIBRATION

4-30.

3000 Volt

Adjustment

4-31.

Before making calibration

adjustments,

the

unit

must have been operated at normal

line voltage

for at

least one hour with an output of

3100 volts. Proceed

as

follows:

a. Set the output of the autotransformer to

115 volts

and set the controls of the Model

415B

as follows:

POWER

POLARITY

HIGH VOLTAGE

Output VOLTAGE

dials

ON

Negative

STDBY/RESET

First dial

to 2500;

second

dial to

500;

others

to zero

b. Connect the output

terminals

of the Model 80F-5

voltage divider across the input terminals of the

Model 88 5A. Connect the divider input across the

Model

415B

OUTPUT

connector.

c. Set the HIGH VOLTAGE

switch to

ON

and adjust

the

Model 885A to

measure

300 volts.

d. Adjust

R26

on the

Amplifier

P/C

Assembly for a

null

Indication

on

the Model 885A. This

adjustment

is

accessible through

the hole in the top

cover.

Make

the adjustment to

better than ±100 millivolts

of 3000 volts

(±10

millivolts on the

Model

885A).

CAUTION!

Use an

insulated

screwdriver

to

adjust R26.

With

negative output polarity,

the

case of this

resistor

is 83

volts above

chassis ground.

With

positive

polarity output, the case would

be

3083 volts

above

chassis ground.

e.

If

the

potentiometer

is

at its

limit

or

the

adjustment

can not be

achieved,

refer to paragraphs

4-46

and

4-48.

f. Set the POLARITY switch to

Positive and

observe

that the

output is

within

the

limits

of step d.

Do

not adjust!

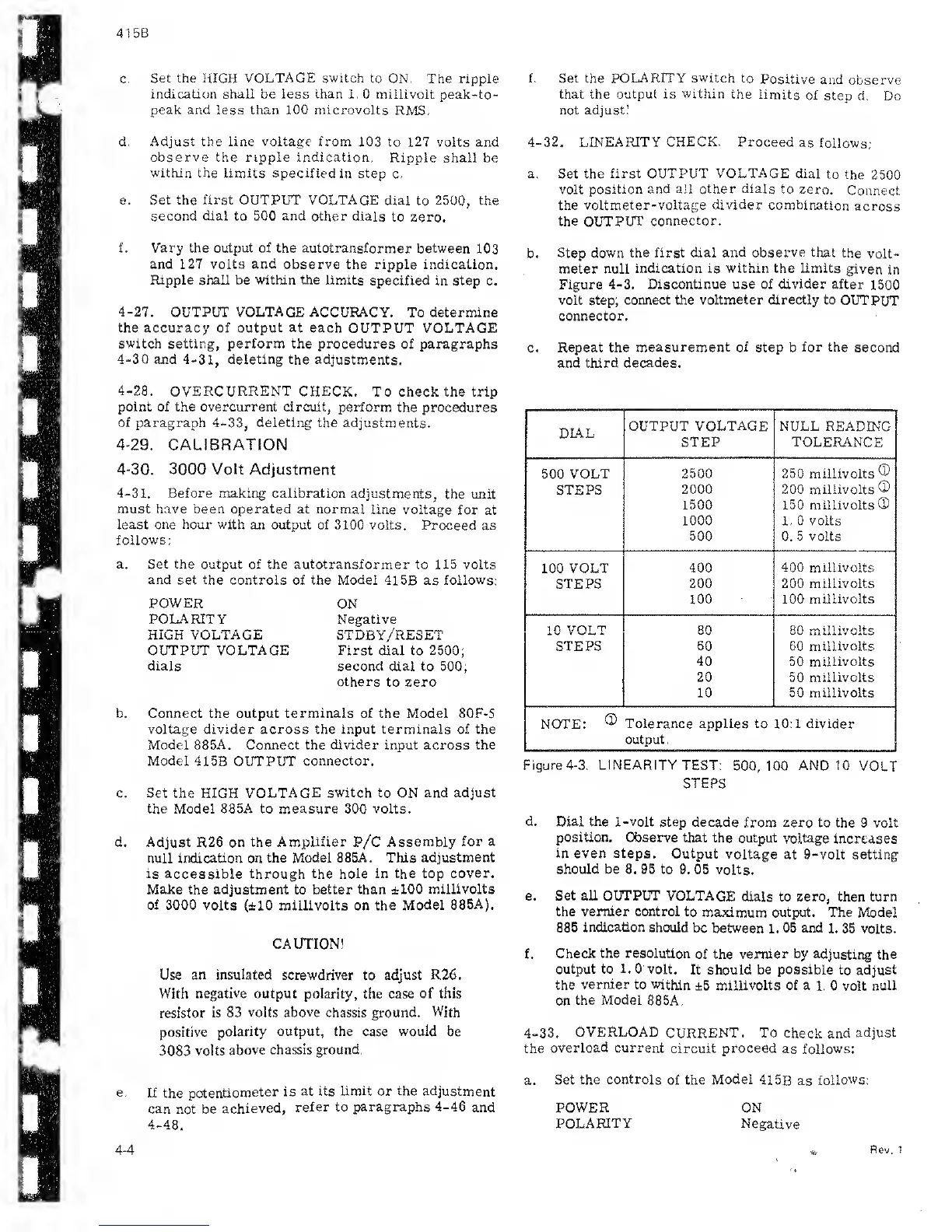

4-32. LINEARITY

CHECK. Proceed

as follows:

a. Set the first OUTPUT

VOLTAGE

dial

to

the 2500

volt

position and all other

dials

to zero.

Connect

the

voltmeter-voltage

divider

combination

across

the OUTPUT

connector.

b. Step

down the first dial

and observe that

the

volt-

meter null

indication is

within

the limits

given

in

Figure

4-3. Discontinue use of

divider

after

1500

volt step;

connect the voltmeter directly to

OUTPUT

connector.

c.

Repeat the

measurement of

step b

for the

second

and third

decades.

DL.4.L

OUTPUT VOLTAGE NULL READING

STEP TOLERANCE

500

VOLT 2500 250 millivolts

®

STEPS

2000 200 millivolts

®

1500 150 millivolts®

1000 1 . 0 volts

500

0.

5 volts

100 VOLT

400 400 millivolts

STEPS

200

200

millivolts

100 100

millivolts

1

n

VOLT

80

»n millivolts

STEPS 60

60

millivolts

40 50 millivolts

20 50 millivolts

10 50 millivolts

NOTE:

®

Tolerance applies to 10:1 divider

output.

Figure

4-3. LINEARITY

TEST:

500,100

AND 10

VOLT

STEPS

d.

Dial the 1-volt step decade

from zero

to the 9 volt

position.

Observe that

the output voltage

increases

in even steps. Output

voltage

at 9-volt setting

should be 8. 95 to

9. 05 volts.

e.

Set all OUTPUT

VOLTAGE

dials to zero, then turn

the vernier control to

maximum output. The Model

885

indication

should

be between 1. 05 and

1. 35 volts.

f.

Check

the resolution

of the

vernier by

adjusting the

output to

1.

0 volt.

It should be

possible

to adjust

the

vernier to within

±5

millivolts of a

1. 0

volt

null

on

the

Model

88 5A.

4-33.

OVERLOAD

CURRENT. To

check and

adjust

the

overload current

circuit

proceed

as

follows:

a.

Set

the controls

of the

Model

41

5B

as

follows:

4-4

POWER

POLARITY

ON

Negative

Rev. 1

Loading...

Loading...