4

Variable frequency inverter controlled pumps/mixers

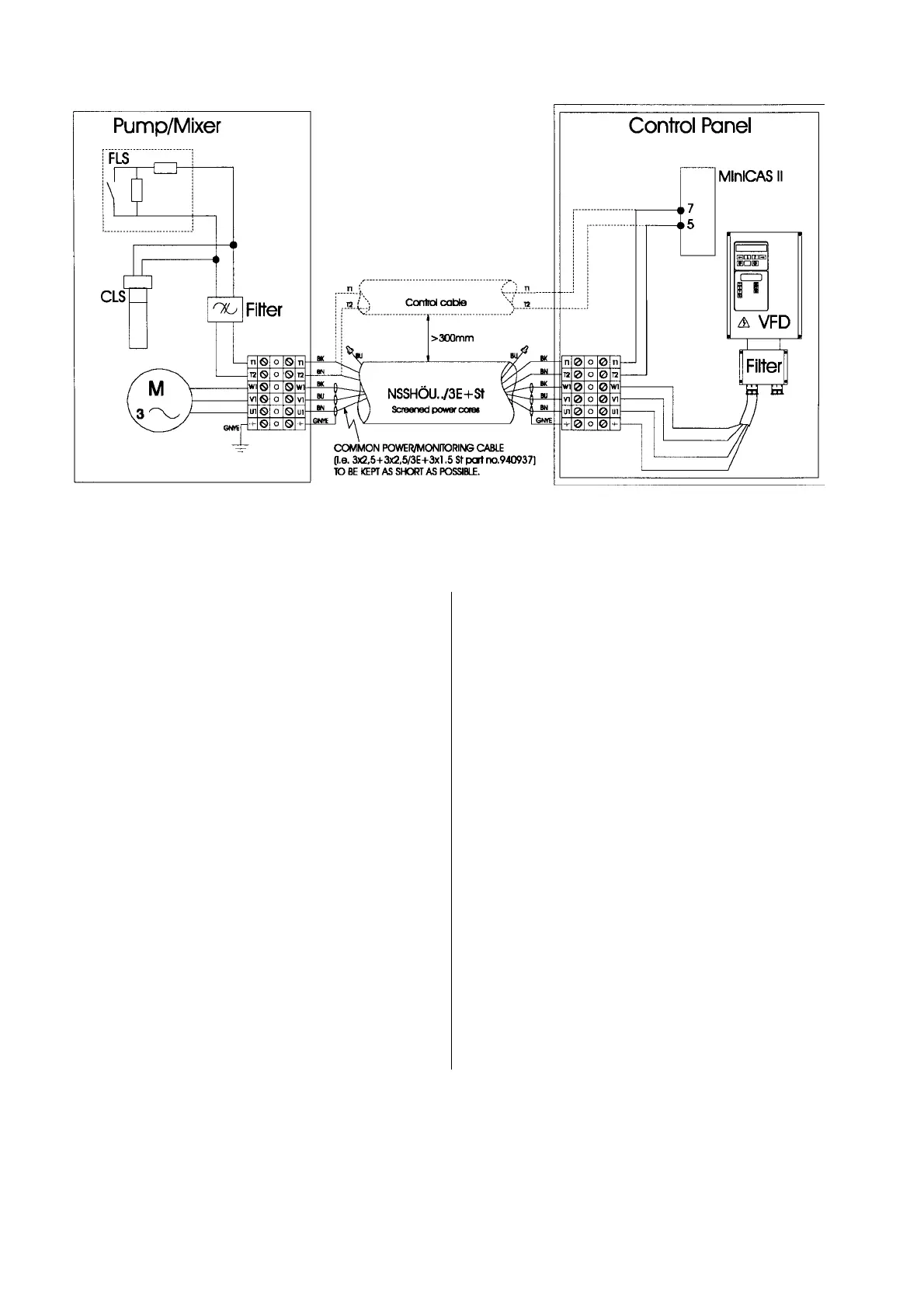

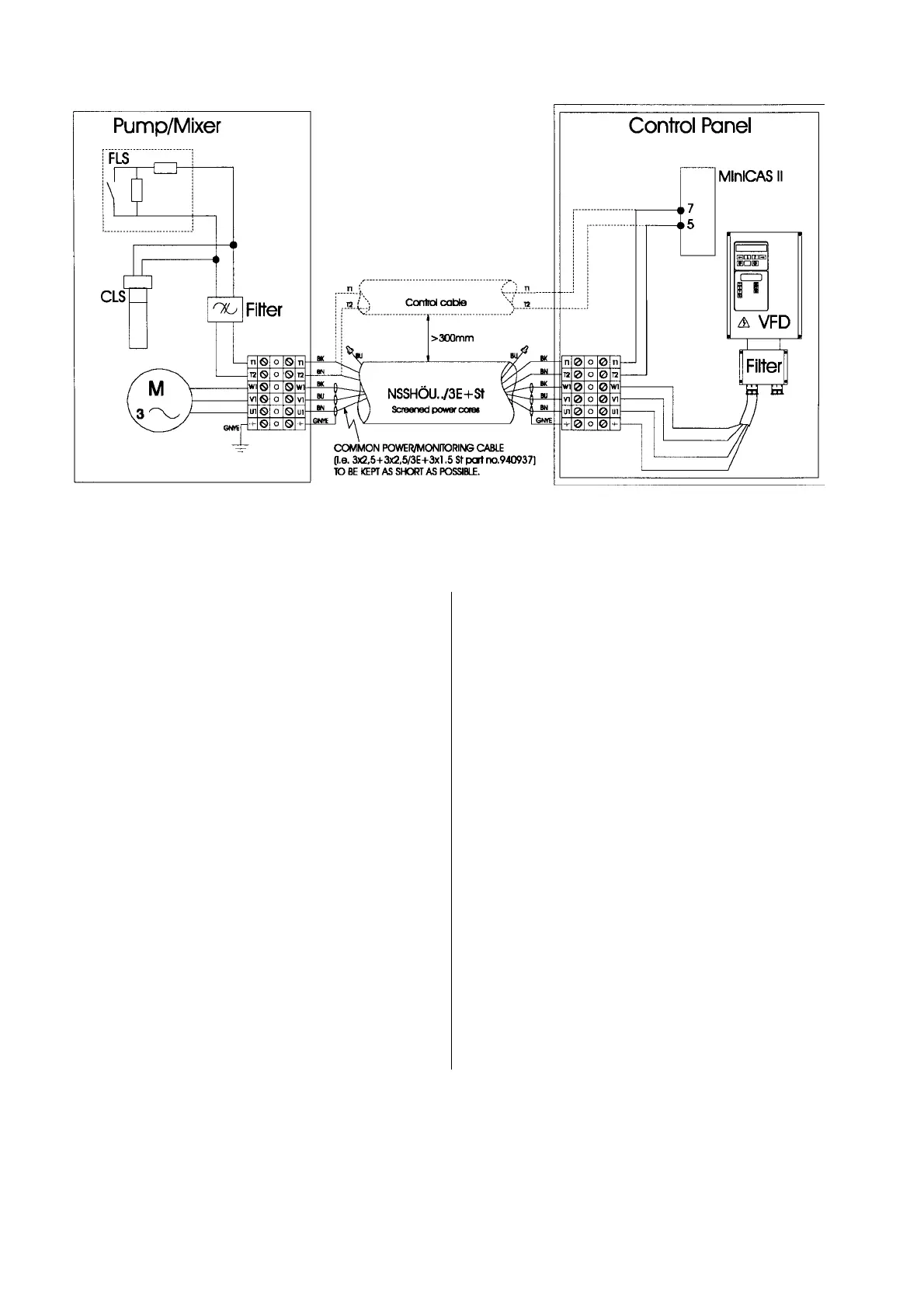

In installations utilising variable frequency inverters for

speed control of pumps, interference from a variable

frequency drive (VFD) may cause nuisance tripping of

monitoring equipment and the electronic sensor CLS.

VFD-interference does not affect FLS and FLS10.

Interference occurs when the pilot cores are in close

proximity to the power cores.

The interference may be suppressed by connecting a

suitable filter

1

between the monitoring conductors (T1,

T2) and ground (PE).

The filter should ideally be situated in the pump/mixer

junction box.

Cables containing both power and pilot cores should

be kept to a minimum length.

The power cable and control cable should be run in

separate cable ducts with a distance of at least

300 mm between them.

Our pumps are CE-marked according to EMC-direc-

tive and the VFD that we buy from a subcontractor

should also be CE-marked. In order to make the VFD

pass the EMC-tests the interconnecting cable be-

tween pump and VFD has to be screened.

1

Available filter kits:

Part no. 6046800

Will fit: 3102, 3127, 4430.

Part no. 6046801

Will fit: 3085, 4410.

Part no. 6046802

Will fit: 3140, 3152, 3170, 3201, 3300.

Part no. 6046804

Will fit: 3231, 3306, 3312, 3351, 3356, 3400, 3501,

3602, 3800, 7045, 7061, 7081, 7101, 7115, 7121.

Part no. 6616000

Will fit: 4630, 4640, 4650, 4660.

Part no. 6616001

Will fit: 4670, 4680.

Loading...

Loading...