1·

22

GROUP 1-

ENGINES

AND

EXHAUST

SYSTEMS

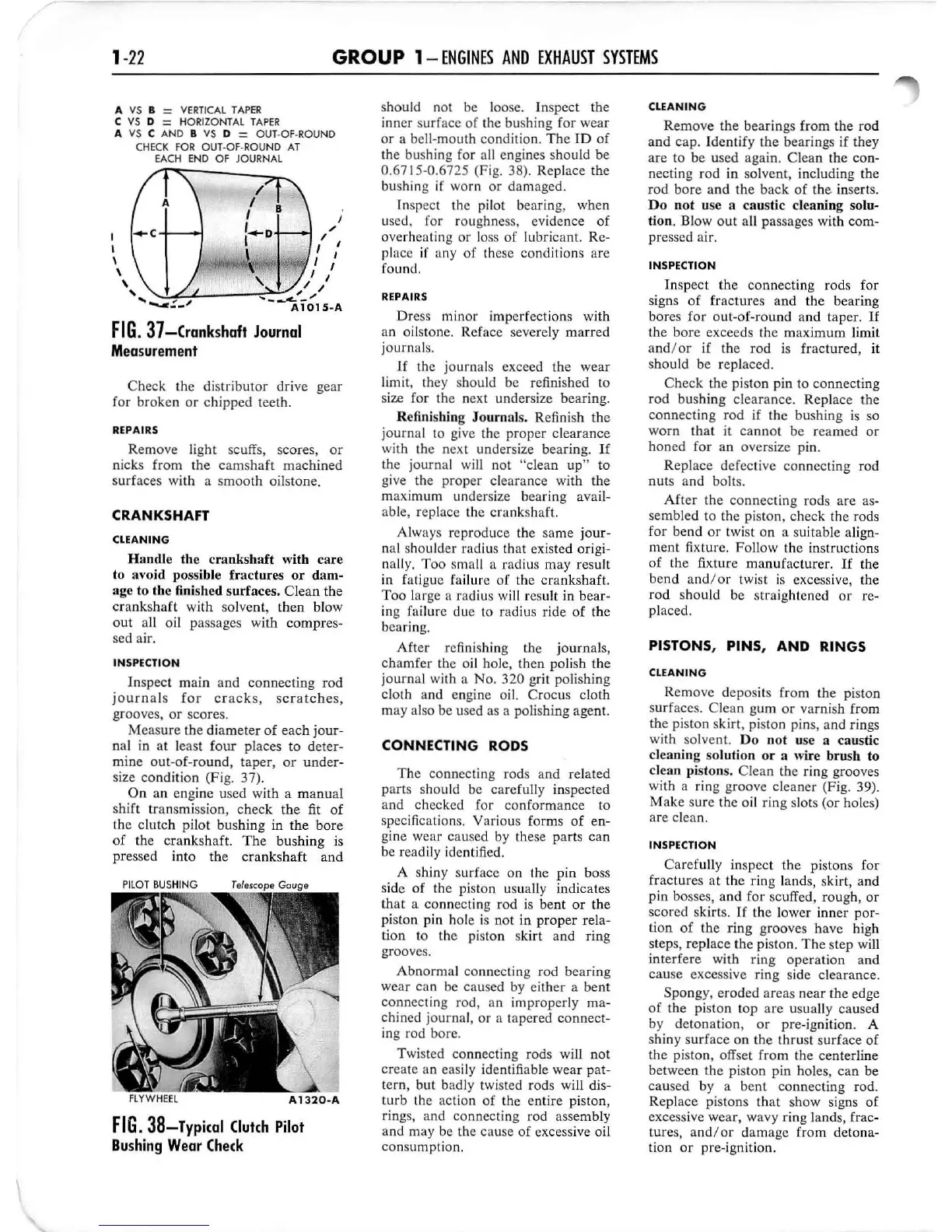

A

VS

B =

VERTICA

L

TAPER

C

VS

D = HOR

IZO

NTAL T

APER

A V$ C AND B

VS

D = OUT-Of-ROUND

CHECK

FOR

OUT-Of-ROUND

AT

EACH

END

OF JOURNAL

I

/

"

I

\

\

\

I I

..

"'

.....

r

~

I

,.

"'"

I I

.,

J J

" I

"-

!..,<W'-_ _ _

~~"

"

.

...

_

-",--"

,

'-"'

:

-'

Al01S-A

FIG.

37-

Crankshafl

Journal

Measuremenl

Check the distributor drive gear

for broken

or

chipped teeth.

REPAIRS

Remove light scuffs, scores,

or

ni

cks from

the

cams

haft

machined

surfaces

with

a smooth oilstone.

CRANKSHAFT

CLEANING

Ha

ndle the c

rank

s

ha

ft with

ca

re

to avoid possible f

ra

ct

ures

or

da

m-

age to the

fi

nished su

rf

aces. Clean the

crankshaft

with solvent, then blow

out all oil passages with compres-

sed air.

INSPECTION

In

spect main and connecting rod

journa

ls

for

cracks,

scratches,

grooves, or score

s.

Measure the diameter

of

each

jour-

nal

in

at

le

ast

four

places to deter-

mine

out

-of-round, taper,

or

under-

size condition (Fig. 37).

On an engine used with a

manua

l

shift trans

mi

ssion, check

the

fit

of

the clutch pilot bushing in

the

bore

of

the crankshaft.

The

bushing

is

pressed into the

cranks

h

af

t and

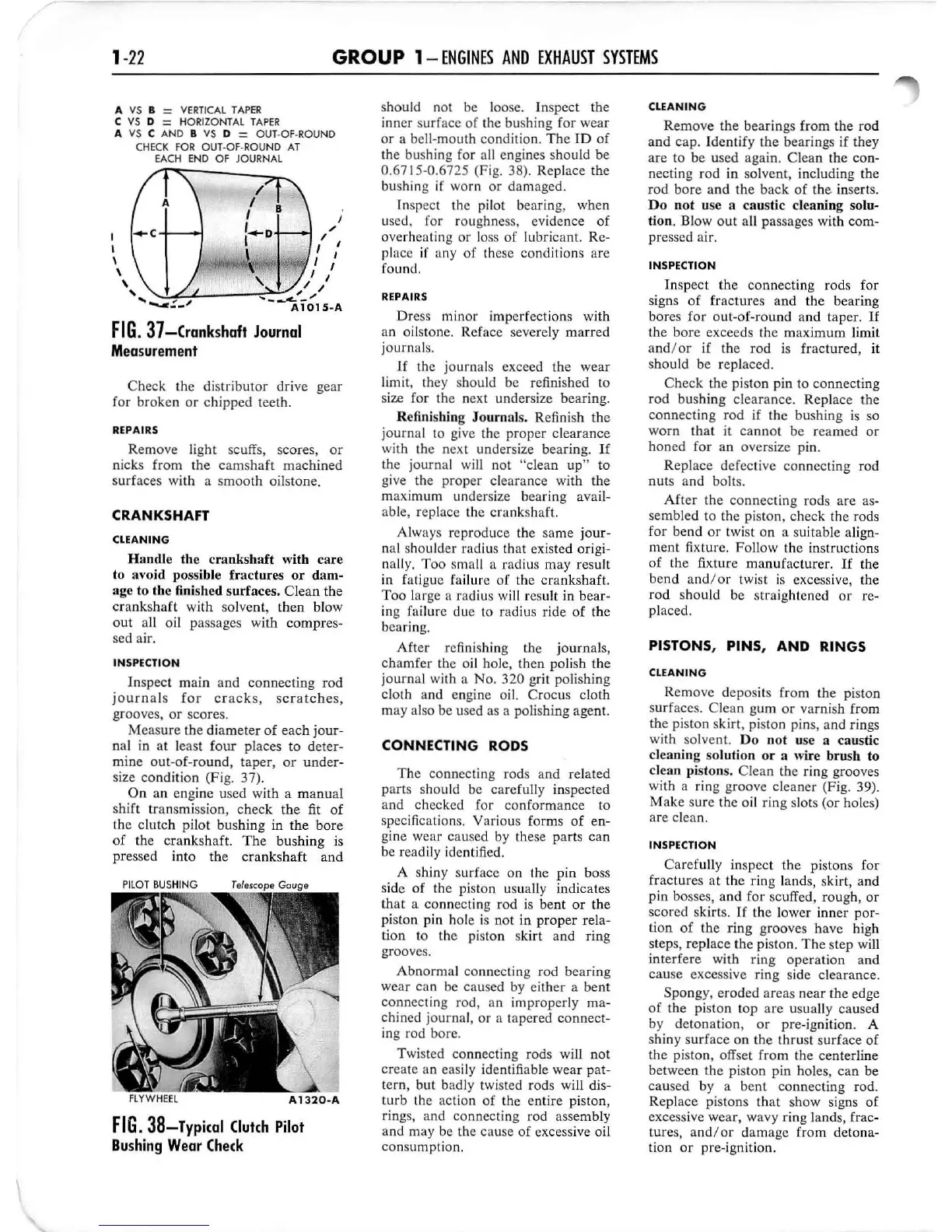

FIG

. 38-Typical

Clulch

Pilol

Bushing

Wear

Check

should not be loose. Inspect the

inner surface of the bushing for wear

or a bell-mouth cond

it

io

n.

Th

e

ID

of

the bushing for all engines should be

0.6715-0.6725 (Fi

g.

38). Replace the

bushing

if worn

or

dam

aged.

Inspect the pilot bearing, when

used, for roughness, evidence

of

overheating

or

lo

ss

of

lubricant. Re-

place if any

of

th

ese conditions are

found.

REPAIRS

Dre

ss

minor imperfections with

an oilstone. Reface severely

marred

journals.

Jf

the journals exceed the wear

limit, they sh

ou

ld be refinished to

size for the next undersize bearing.

R

efi

nis

hi

ng

Jo

urnals. Refinish the

journ

al to give the proper clearance

with the next undersize bearing.

If

the j

ourna

l w

ill

not "clean

up"

to

give the proper clearance with the

maximum undersize bearing avail-

able, replace the

cranks

haft.

Always reproduce the same

jour-

nal shoulder radius that existed origi-

nally.

Too

small a radius may result

in fatigue failure of the crankshaft.

Too

lar

ge

a radius

will

result in bear-

ing fai lure due

10 radius ride

of

the

bearing.

Aft

er

refi

ni

shing the journals,

c

hamf

er

the

oi

l hole, then po

li

sh

the

journ

al with a

No

, 320 grit polishing

cloth a

nd

engine oil. Crocus cloth

ma

y also be used as a polishing agent.

CONNECTING RODS

The

connecting rods and related

parts shou

ld

be

caref

ully inspected

and checked for conformance to

specifications. Various forms

of

en-

gine wear caused by

Ihese parts can

be readily

id

entified.

A shiny surface on the pin boss

side

of

the piston usually indicates

that

a connecting rod

is

bent

or

the

pi

ston pin hole is not in

proper

rela-

tion to the

pi

ston skirt and ring

groove

s.

Abnorma

l connect

in

g rod

bear

ing

wear can be

ca

used by eith

er

a bent

connecting rod, an

im

properly

ma

-

chined journal,

or

a tapered connect-

ing rod bore.

Twisted connecting rods will not

create an eas

il

y

id

en

tifi

able wear pat-

tern, but badly twisted rods will dis-

turb

the action

of

the entire piston,

rin

gs,

and connecting rod assembly

and

may be the cause

of

excessive

oi

l

consumption.

CLEANING

Remove

the

be

ar

in

gs from

the

rod

and cap. Identify

the

b

ear

ings if they

are

to

be used again. Clean the con-

necting rod in solvent, including the

rod

bore

and

th

e back

of

the inserts.

Do

n

ot

use a

ca

ustic cleaning solu-

tion.

Blowout

all passages with com-

pressed air.

INSPECTION

In

spect

the

connecting rods for

signs

of

fractures and

the

bearing

bor

es for out-of-round and taper.

It

the

bore

exceeds the maximum limit

and/

or

if the rod

is

fractured, it

should be replaced.

Check the piston pin to connecting

rod

bushing clearance. Replace the

connecting rod if the bushing

is

so

worn that it

cannot

be reamed

or

h

oned

for an oversize pin.

Re

pl

ace defective connecting rod

nut

s and bolts.

After

the

connect

in

g rods are as-

sembled to the

pi

ston, check the rods

for bend

or

twist on a suitable align-

ment fixture. Follow the instructions

of

the fixture manufacturer.

If

the

bend

and/or

twi

st is excessive, the

rod

should be straightened

or

re-

placed.

PISTONS

,

PINS,

AND

RINGS

CLEANING

Remove deposits from the piston

s

urf

aces. Clean gum

or

varnish from

the

pi

ston skirt,

pi

ston pins, and rings

with solvent.

Do

not use a

ca

ustic

clea

ni

ng

so

lution or a wi

re

br

ush to

clean pistons. Clean the ring grooves

with a ring groove cl

eane

r (Fig. 39).

Make sure the oil ring slots (or holes)

are c

le

an.

INSPECTION

Carefu

lly

in

spect

the

pistons for

fractures

at

the ring land

s,

skirt, and

pin bosses,

and

for scuffed,

roug

h,

or

scored skirt

s.

I f the lower inner por-

tion

of

the

ring

grooves have high

step

s,

replace

the

piston.

The

step will

inte

rf

e

re

with ring operation and

cause

excessive ring side clearance.

Spongy, eroded

areas

near

the edge

of

the

piston top

are

us

ua

ll

y caused

by detonation,

or

pre-ignition. A

shiny s

urf

ace

on

the

thrust surface

of

the

piston, offset f

rom

the centerline

between

the

piston p

in

holes,

can

be

ca

used by a

bent

conn

ec

ting rod.

Replace pistons th

at

show signs

of

excessive wear, wavy ring lands, frac-

ture

s,

and

/or

damage

from

detona-

tion

or

pre

-i

gnition.

Loading...

Loading...