Every 6000 miles or 6 Months 1•9

1

1 Simply pull the oil filler cap from the rocker

cover and, where applicable, disconnect the

hose(s) from the cap.

2 Inspect the filler cap, and if necessary clean

the cap using clean petrol to remove any

deposits.

3 Ensure that the cap is completely dry

before refitting.

1 Visually inspect the engine joint faces,

gaskets and seals for any signs of water or oil

leaks. Pay particular attention to the areas

around the rocker cover, cylinder head, oil

filter and sump joint faces. Bear in mind that

over a period of time some very slight

seepage from these areas is to be expected

but what you are really looking for is any

indication of a serious leak. Should a leak be

found, renew the offending gasket or oil seal

by referring to the appropriate Chapter(s) in

this manual.

2 Similarly, check the transmission for oil

leaks, and investigate and rectify and

problems found.

3 Check the security and condition of all the

engine related pipes and hoses. Ensure that

all cable-ties or securing clips are in place and

in good condition. Clips which are broken or

missing can lead to chafing of the hoses,

pipes or wiring which could cause more

serious problems in the future.

4 Carefully check the condition of all coolant,

fuel and brake hoses. Renew any hose which

is cracked, swollen or deteriorated. Cracks

will show up better if the hose is squeezed.

Pay close attention to the hose clips that

secure the hoses to the system components.

Hose clips can pinch and puncture hoses,

resulting in leaks. If wire type hose clips are

used, it may be a good idea to replace them

with screw-type clips.

5 With the vehicle raised, inspect the fuel

tank and filler neck for punctures, cracks and

other damage. The connection between the

filler neck and tank is especially critical.

Sometimes a rubber filler neck or connecting

hose will leak due to loose retaining clamps or

deteriorated rubber.

6 Similarly, inspect all brake hoses and metal

pipes. If any damage or deterioration is

discovered, do not drive the vehicle until the

necessary repair work has been carried out.

Renew any damaged sections of hose or pipe.

7 Carefully check all rubber hoses and metal

fuel lines leading away from the petrol tank.

Check for loose connections, deteriorated

hoses, crimped lines and other damage. Pay

particular attention to the vent pipes and

hoses which often loop up around the filler

neck and can become blocked or crimped.

Follow the lines to the front of the vehicle

carefully inspecting them all the way. Renew

damaged sections as necessary.

8 From within the engine compartment,

check the security of all fuel hose attachments

and pipe unions, and inspect the fuel hoses

and vacuum hoses for kinks, chafing and

deterioration.

9 Where applicable, check the condition of

the oil cooler hoses and pipes.

10 Check the condition of all exposed wiring

harnesses.

11 Also check the engine and transmission

components for signs of fluid leaks.

Check the tightness of the exhaust

manifold securing nuts using a torque wrench.

Note: Before carrying out any carburettor

adjustment, ensure that the contact breaker

points, ignition timing and spark plug gaps (as

applicable) are set as specified and that the

distributor is operating correctly (where

applicable). To carry out the adjustments an

accurate tachometer will be required and the

use of an exhaust gas analyser (CO meter) is

also preferable.

Models with Ford VV carburettor

Idle speed

1 With the engine at normal operating

temperature, connect a tachometer in

accordance with the manufacturer’s

instructions.

2 Disconnect the wiring multi-plug from the

radiator cooling fan thermostatic switch in the

thermostat housing and bridge the two

contacts in the plug using a suitable length of

wire. This is necessary so that the cooling fan

runs continuously during adjustment.

3 On automatic transmission models slacken

the adjuster screw on the throttle valve shaft

lever to give clearance of 2 to 3 mm (0.079 to

0.118 in) - see Chapter 7, Part B.

4 Ensure that the air cleaner is fitted and that

its vacuum hoses are not in any way trapped

or pinched, particularly between the air cleaner

body and the top face of the carburettor.

5 Run the engine at 3000 rpm for 30 seconds,

then allow it to idle and note the idle speed. If

using an exhaust gas analyser it should be

noted that initially the CO% reading will rise,

but then fall and stabilise after a period of 5 to

25 seconds. The CO reading should then be

as specified.

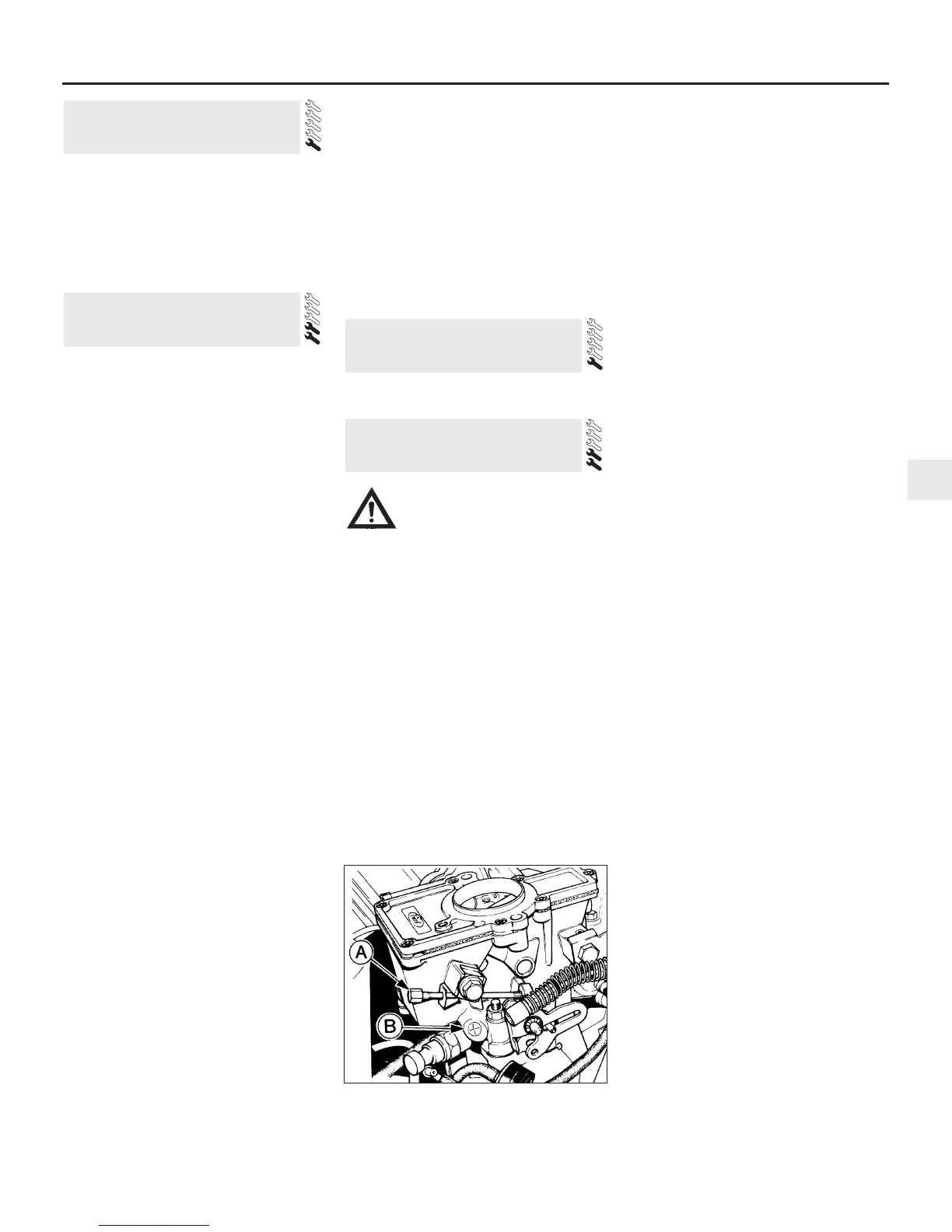

Idle mixture

6 If necessary, adjust the idle speed

adjustment screw to give the specified idle

speed (see illustration).

7 Adjustment of the CO content (mixture) is

not normally required during routine

maintenance, but if the reading noted in

paragraph 5 is not as given in the

Specifications first remove the tamperproof

plug, prising it free using a small screwdriver.

8 Run the engine at 3000 rpm for 30 seconds,

then allow it to idle. Adjust the mixture screw

(see illustration 10.6) within 30 seconds. If

more time is required run the engine at 3000

rpm again for 30 seconds.

9 Adjust the idle speed if necessary and

recheck the CO content.

10 Fit a new tamperproof plug to the mixture

adjuster screw on completion. It should be

noted that mixture adjustment without a CO

analyser is not accurate and therefore not

recommended.

11 On completion disconnect the

instruments, remove the cooling fan bridging

wire and reconnect the multi-plug.

12 On automatic transmission models adjust

the downshift linkage (Chapter 7, Part B).

Models with Weber 2V carburettor

13 The procedure is the same as for the Ford

VV carburettor as described previously in this

Section, but the adjusting screw locations are

as shown (see illustrations).

Models with Bosch K-Jetronic

fuel injection system

14 The idle speed and fuel mixture

adjustments will normally only be required

after the installation of new components.

10 Idle speed and mixture

adjustment

9 Exhaust manifold nut check -

RS Turbo models

8 Fluid leak check

7 Oil filler cap cleaning - OHV

and HCS engines

10.6 Idle speed adjustment screw (A) and

mixture adjustment screw (B) - Ford VV

carburettor

Caution: Certain adjustment

points in the fuel system are

protected by “tamperproof”

caps, plugs or seals. In some

EEC countries (though not yet in the UK)

it is an offence to drive a vehicle with

broken or missing tamperproof seals.

Before disturbing a tamperproof seal,

satisfy yourself that you will not be

breaking any local or national laws by

doing so, and fit a new seal after

adjustment is complete where required by

law. Do not break tamperproof seals on a

vehicle which is still under warranty.

Loading...

Loading...