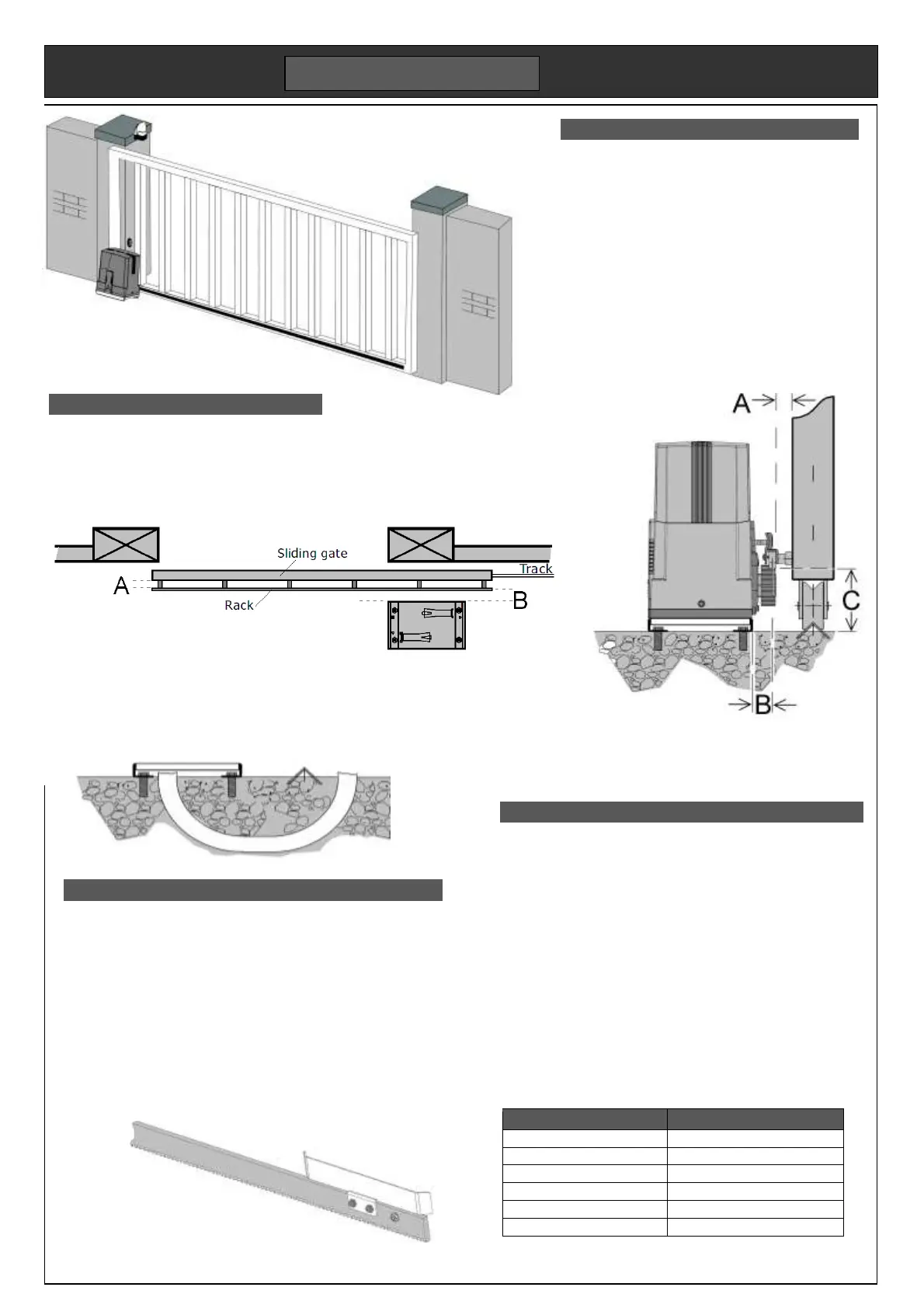

Mechanical

Gates must be level and free running on a ground

track, or on cantilever gate bearings. It is usual to

support the gate at the top with nylon rollers. Two

gates mounted on the same track may slide from

each side of an opening to meet in the centre.

The motor’s steel base plate is set in concrete at

the same time as the gate track. Their relative

height will depend on the size of the gate wheel

used, typically 80 – 100mm diameter.

The motor can be packed higher to meet the rack

if required. The toothed rack normally has slotted

mounting holes to allow accurate adjustment.

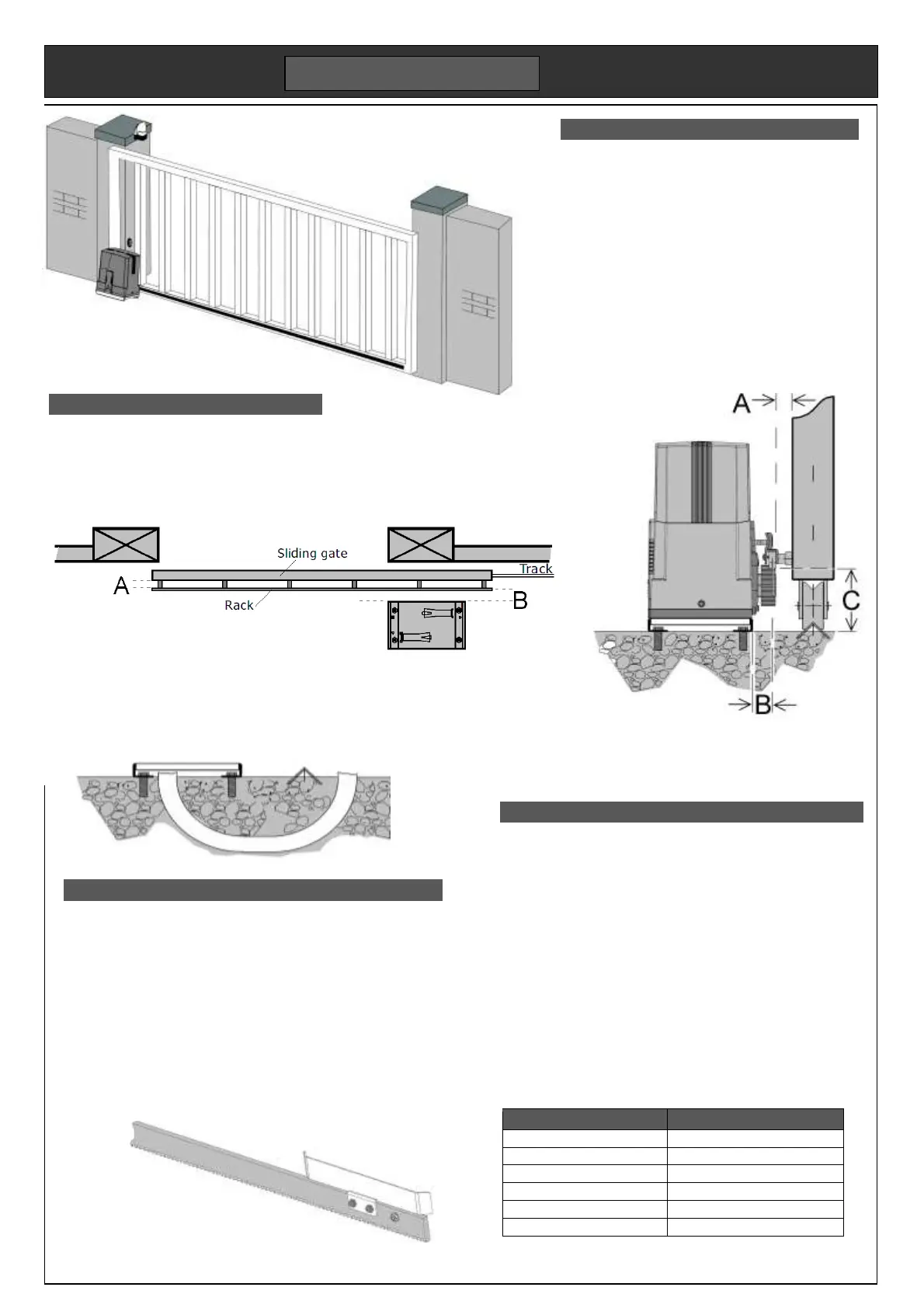

Mounting the motor and rack

Slotted holes in the motor base allow some adjustment. Mount

the motor square to the gate with the rack central to the pinion.

The toothed rack is best fitted using the motor pinion to set the

height. Make the fixing near the motor, then slide the gate along

to set next fixing height. Allow a 2mm gap between rack and

pinion to reduce drag and wear. This can be done by packing

the motor up by 2mm, then remove the packing later.

Skis are brackets bolted to the toothed rack to strike the motor

limit switches. Slide the gate to the open position. Set the ski so

that it bends the spring. Repeat for the closed position. Final

adjustment can be made when motor is running.

Alignment dimensions .

A Allow 25mm from the face of the gate to the back of the toothed rack.

B Allow 30mm from the centre the toothed rack to the edge of the base plate.

C Allow a min 92mm from underside of the base plate to bottom of toothed rack.

For wheels bigger than 100mm diameter, it may be necessary to cast the base plate into

a raised concrete plinth. If not, the base plate can be bolted to a ground level concrete

pad incorporating the ground track. We recommend fixing studding with resin because

the motor’s high shear force and vibration is inclined to loosen expansion bolts. Always

use washers and self locking nuts.

Ducts & Cabling

When casting the foundations, be sure to provide one or more

cable ducts to the underside of the motor base. It will not be

possible to run cables above the gate’s ground track. While

installing the ground track, it is useful to run another duct or

direct burial cable under the track to the opposite gate post.

Align the ducts with the fifth hole in the base plate. Cables

will be required for mains supply, photo beams and any

access control devices, for example an intercom. The motor

has two cable glands in the base for the cables.

At minimum, you will need a low voltage cable to each gate

post, and a mains supply to the motor base. The cable type

will depend on the duct standard. An eight core outdoor

grade alarm cable is adequate. More than one device at the

same location can be run from one cable using the universal

wiring scheme.

2 core + Earth, typ. 1.5mm²

2 core + Earth, typ. 0.75mm²

Skis fixing viewed from the motor side

Loading...

Loading...