9

EN

OPERATING AND MOUNTING INSTRUCTIONS

S1 Safes according to EN 14450

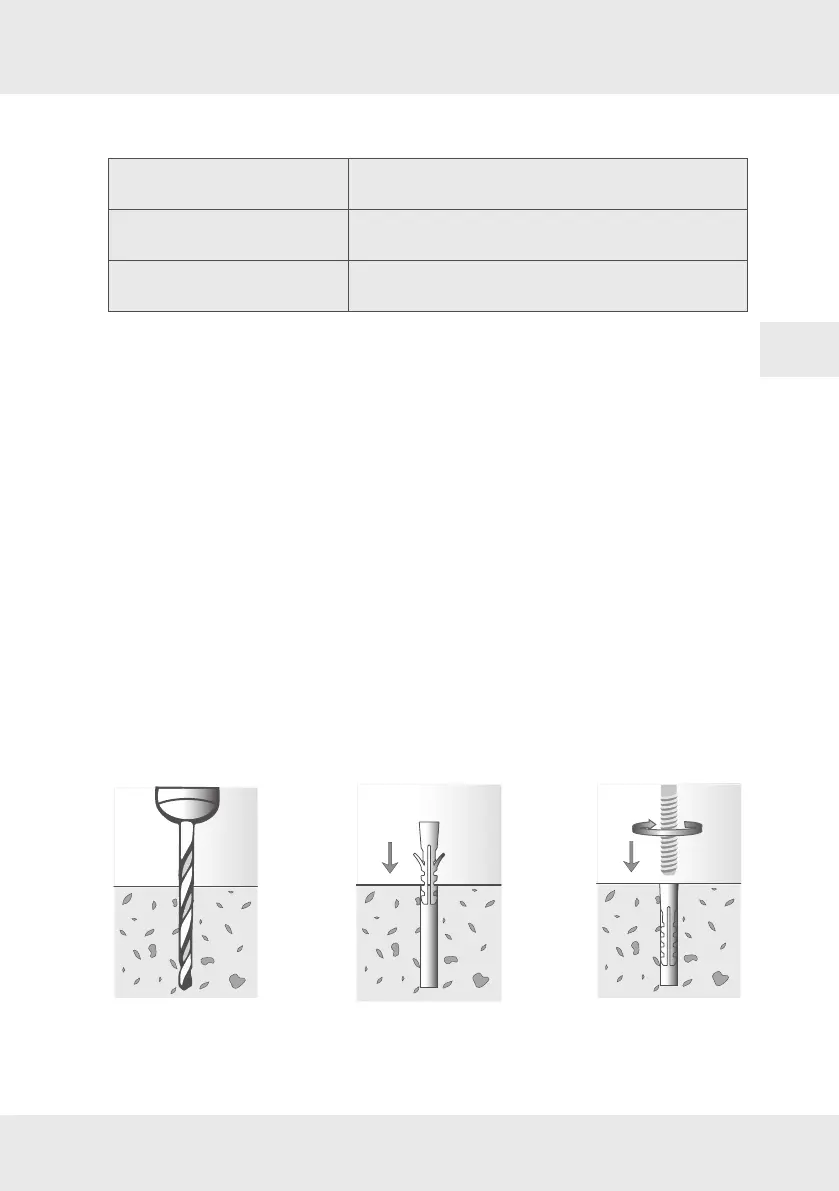

1) Mark drilling

position and drill

(Ø16 mm, at least 100

mm deep)

2)Cleanthedrillhole

and hammer in the

dowels

3) Position the safe

and insert screw M12

with U-washer

Anchor bolt or threaded rod: Thread M12 / strength class 8.8

Hexagon nut DIN / ISO 934: Thread M12 / strength class 8.8

Washer DIN / ISO 125: Internal diameter 13 mm / external diameter 24 mm

/ thickness 2.5 mm

However, the fastening material must meet the following requirements:

Dowel:

The expansion dowel M12S provided is suitable for load-bearing surfaces made of concrete,

aerated concrete, solid brick or sand-lime bricks.

Important:

Beforeanchoringit,makeabsolutelycertainthatthesuboorissuitableforthefastening

material provided, and that there are no cables, lines, pipes or the like in the drilling area.

Otherwise, another type and / or place of fastening must be selected.

3.2 ANCHORING WITH THE ENCLOSED FITTING MATERIAL

Set up the vault at the intended location and align it so it is in balance. Mark the drilling po-

sition in the area to be anchored through the anchoring holes in the vault, and then remove

the vault again from the drilling area.

Drill a minimum depth of 100 mm into the substrate using a Ø 16 mm stone drill. Now clean

the borehole (extract drilling dust) [1].

Insertthedowelintothehole[2]andreturnthevaulttoitsnalposition.Nowboltthesafe

with the screw M12 and the washer. The thread can be easily chamfered so it is easier to

insert the screw or threaded rod [3].

In the event of break-in / theft, your insurer will not be liable for property damage or

pecuniary damage if improperly anchored.

Loading...

Loading...