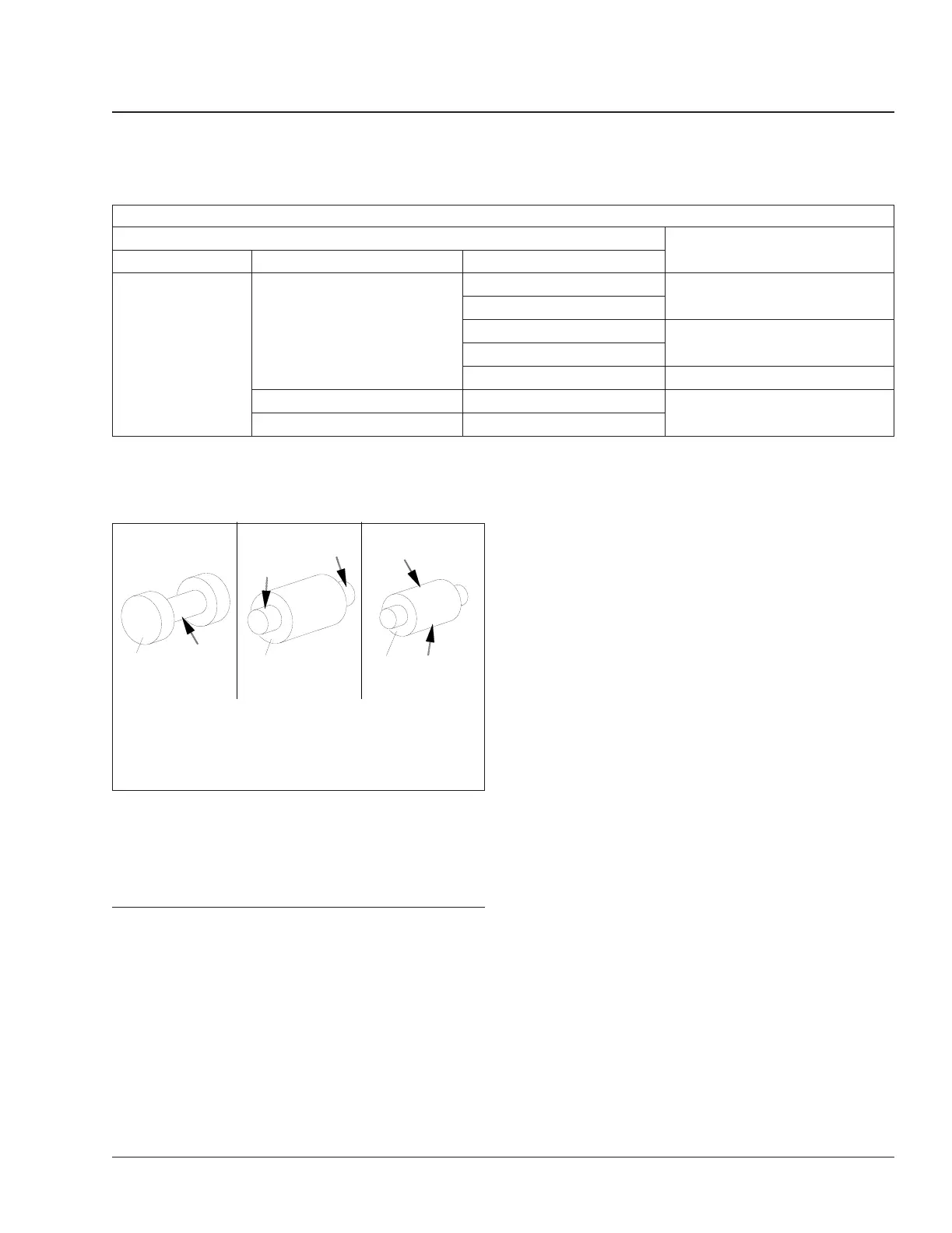

Brake Chamber Stroke Specifications

Chamber

Max Applied Stroke: inch (mm)

Manufacturer Type

*

Size

†

Meritor

Standard Stroke

9

Less than 1-1/2 (38)

12

16

Less than 1-3/4 (44)

20

24 Less than 1-7/8 (48)

Long Stroke 24

Less than 2 (51)

Standard Stroke 30

*

Long stroke design is indicated by a tag, or embossing, on the brake chamber.

†

Specifications are relative to a brake application with 80 to 90 psi (550 to 620 kPa) air pressure in the brake chambers.

Table 3, Brake Chamber Stroke Specifications

42–13 Versajust Slack Adjuster

Inspection and

Lubrication

IMPORTANT: Perform the Brake Inspection

maintenance operation before lubricating the

slack adjusters.

1. Visually check for physical damage, such as bro-

ken air lines and broken or missing parts.

2. Using a quality multipurpose chassis lubricant,

NLGI Grade 2, lubricate the slack adjuster

through the grease fitting until clean lubricant

flows from the grease relief opening in the boot.

3. Perform the "In Service Inspection."

In Service Inspection

1. Apply and release the brakes several times while

observing the slack adjuster. The slack adjuster

and brake actuator should move freely, without

binding or interference, and should return to the

full released position. Observe the looseness that

exists between the clevis and adapter bushing

and the yoke and link pins and their mating parts

(clevis, body, link). Replace these parts if loose-

ness appears excessive. Make certain the brake

actuator pushrod jam nut is tightened securely.

2. Inspect the slack adjuster for physical damage,

paying attention to the link, boot, and clevis. If

any components are damaged, repair or replace

them as necessary.

3. Measure the brake actuator pushrod stroke while

making an 80 to 90 psi (552 to 621 kPa) brake

application. Actuator pushrod strokes should not

exceed the values shown in

Table 4 and

Table 5. To achieve the correct pressure for this

test, build the system pressure up to a 100 psi

(690 kPa). Shut down the engine. Fan the

brakes to attain a 90 to 95 psi (621 to 655 kPa)

reading. Make and hold a full brake application

while the strokes are checked.

03/02/2004

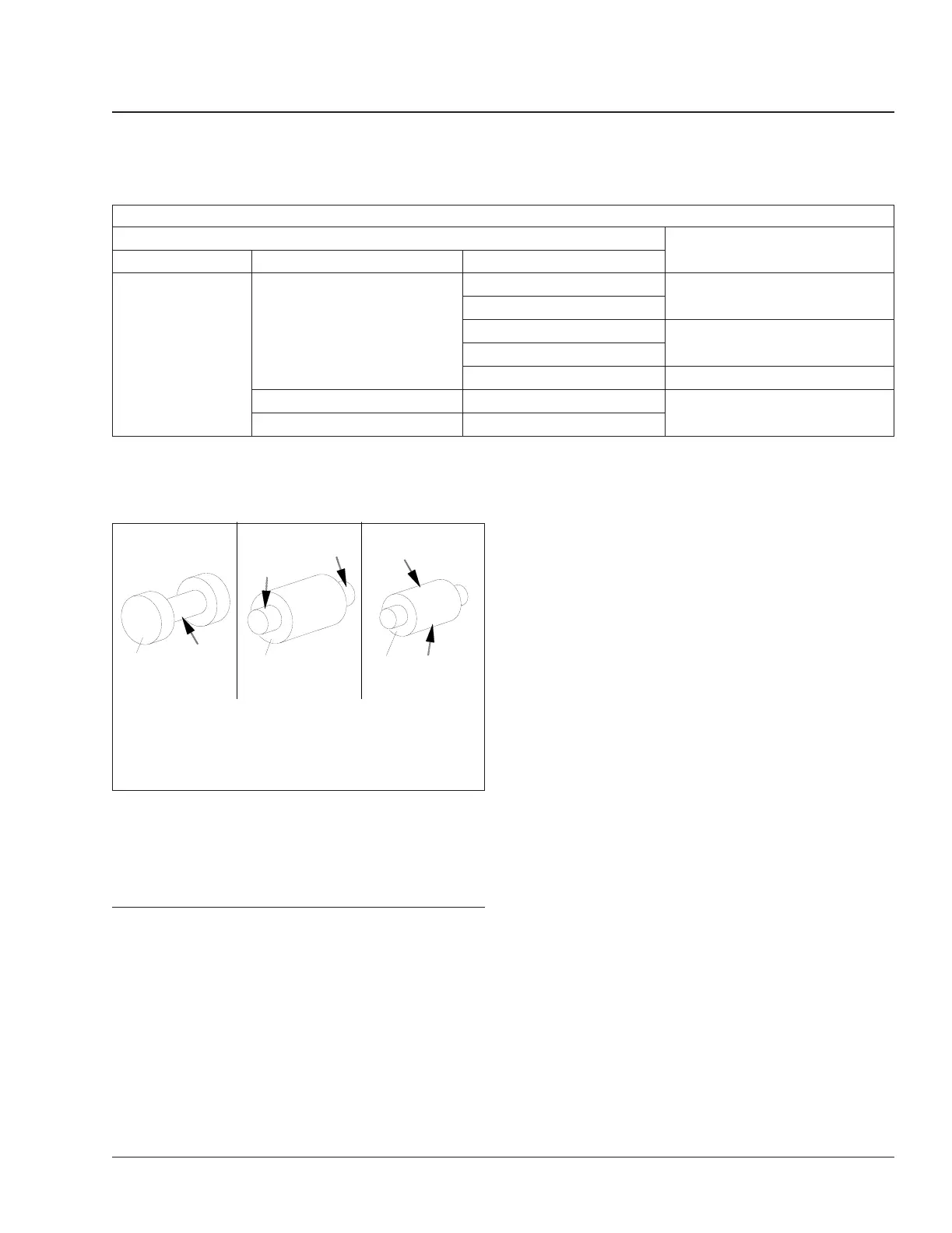

1

2

3

f430370

1. Cam Roller Pin Lube Point (Q Series)

2. Cam Roller Pin Lube Points (Q, Q Plus, and P

Series)

3. Cam Anchor Pin Lube Points (Q, Q Plus, and P

Series)

Fig. 12, Cam and Anchor Roller Pin Lubrication Points

Brakes 42

Recreational Vehicle Chassis Maintenance Manual, July 2018 42/13

Loading...

Loading...