2. Check the exhaust pipe, bellows, and each ex-

haust seal clamp for leakage, wear, cracks, or

damage. Replace damaged components as

needed. If leakage exists at a clamp, tighten the

nuts to the required torque. If leakage persists,

install a new exhaust seal clamp. Do not reuse

seal clamps. Once a seal clamp is loosened or

removed, it must be replaced.

3. If present, check the condition of the insulation

material around the exhaust pipe between the

turbocharger and the ATD.

4. Check the ATD mounting bands for tightness.

Tighten to 30 lbf·ft (41 N·m) if needed. Do not

overtighten.

5. Check for leaks around the clamps that attach

the ATD in the ATS, and around the clamps that

retain the DPF in the ATD. No leaks are allowed

anywhere in the system.

6. Check all sensors attached to the ATD for leaks

or damaged wires. No leaks are allowed.

7. Check the DPF exterior surface for dents or

other damage. A dent over 3 inches (76 mm) in

diameter and 1/4-inch (6-mm) deep could cause

internal damage to the DPF, causing it to mal-

function.

8. Check the SCR catalyst for dents and other

damage.

9. Check for heat discoloration on the surface of

the ATD. Heat discoloration may indicate internal

damage; especially around the DPF.

NOTE: Diesel exhaust fluid creeps, causing

white crystals to form around the line fittings.

The presence of crystals does not mean the

system has a leak. Replacing fittings or trouble-

shooting components is not necessary unless

there is a system failure or a fault code.

10. Check the DEF tank, pump, metering unit, and

lines for leaks. See

Group 49 of the Recre-

ational Vehicle Chassis Workshop Manual for

repair procedures.

11. Check any wires, lines, or hoses within 4 inches

(10 cm) of the exhaust system for heat damage.

Repair or reroute as needed.

Diesel Exhaust Fluid (DEF) Filter

Replacement

The Environmental Protection Agency’s 2010 regula-

tions require lower nitrogen oxide (NOx) exhaust

emissions. Selective catalytic reduction (SCR) uses

diesel exhaust fluid (DEF) to lower NOx emissions in

the vehicle exhaust. A filter in the DEF pump pre-

vents clogging of the DEF metering unit injection

nozzle.

See the engine manufacturer’s maintenance manual

for DEF filter replacement instructions and mainte-

nance intervals.

EPA07 Exhaust System

Definitions of ATS Terms

Refer to the following list of definitions of ATS terms

and components.

• Aftertreatment System (ATS) — the entire ex-

haust system from the turbocharger to the tail

pipe.

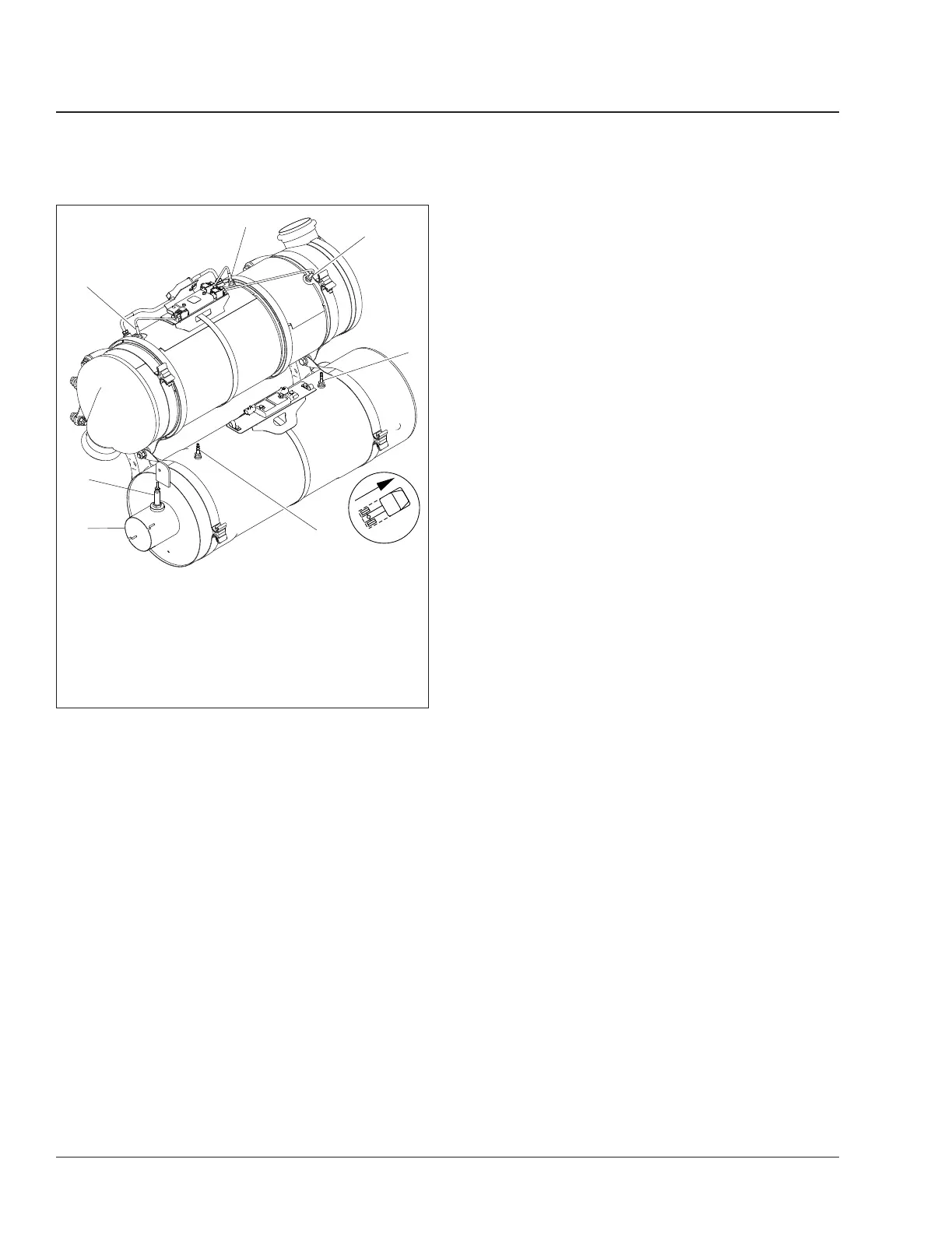

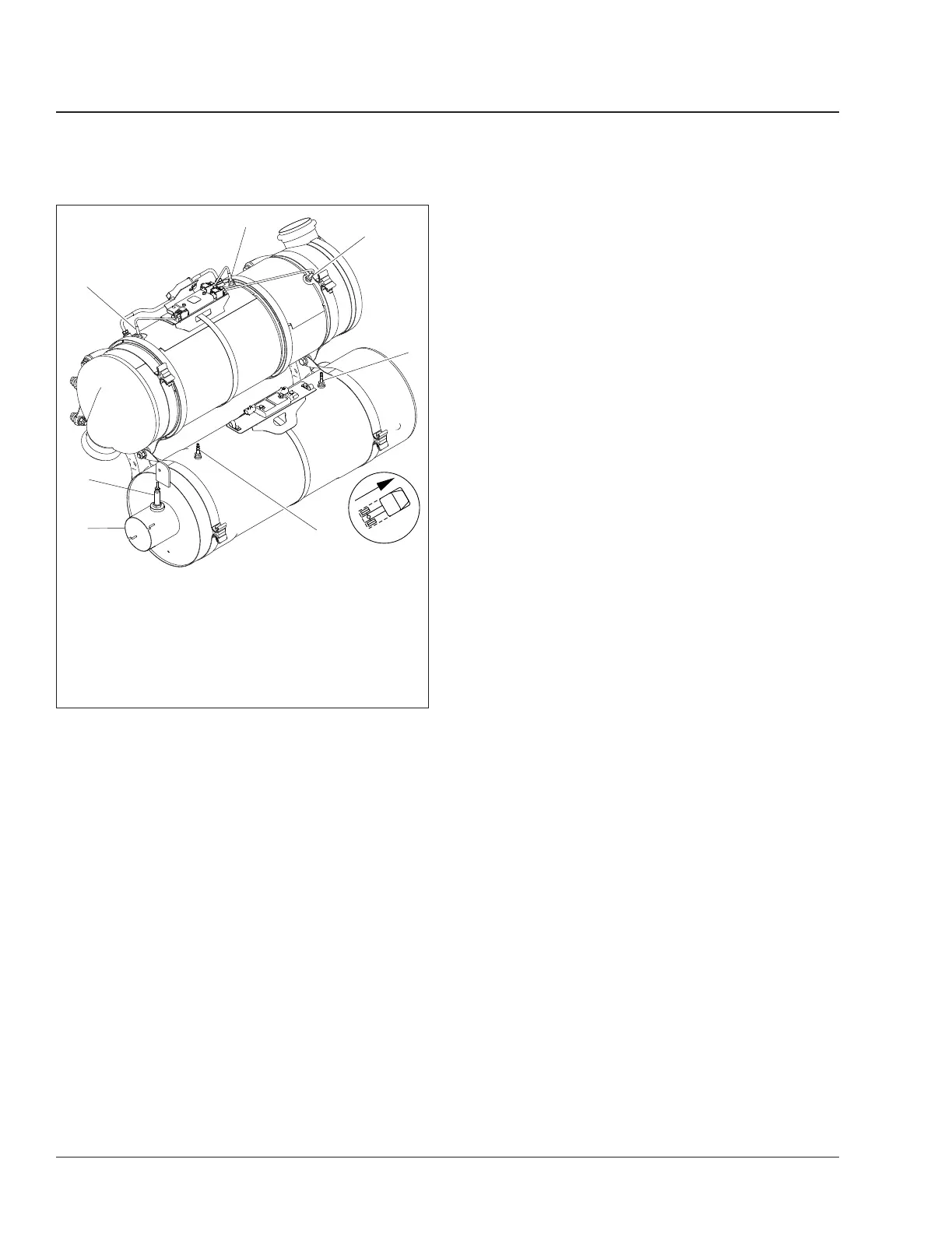

10/20/2009 f490386

1

2

3

4

5

6

7

1. Exhaust Outlet

2. SCR Outlet NOx Sensor

3. DPF Outlet Pressure Sensor

4. DPF Intake Pressure Sensor

5. DPF Inlet Temperature Sensor

6. SCR Inlet Temperature Sensor

7. SCR Outlet Temperature Sensor

Fig. 1, Cummins ATD Sensor Locations

Exhaust49

Recreational Vehicle Chassis Maintenance Manual, November 201549/2

Loading...

Loading...