• Lubriplate Syn Flush

• Lubriplate Pure Flush

• Whitmore’s Flushing Oil

• Medallion

™

Flushing Oil Kosher

6. Using degreaser, clean the thread on the drain

hole and drain plug.

7. Install the drain plug.

8. Fill the fan drive gearbox with Mobil® Delvac

75W–90 lubricant until the lubricant starts to

come out of the oil level plug hole.

9. Using degreaser, clean the thread on the oil level

and fill holes and both plugs.

10. Install the plugs, making certain that the

breather/fill plug is used in the fill plug hole.

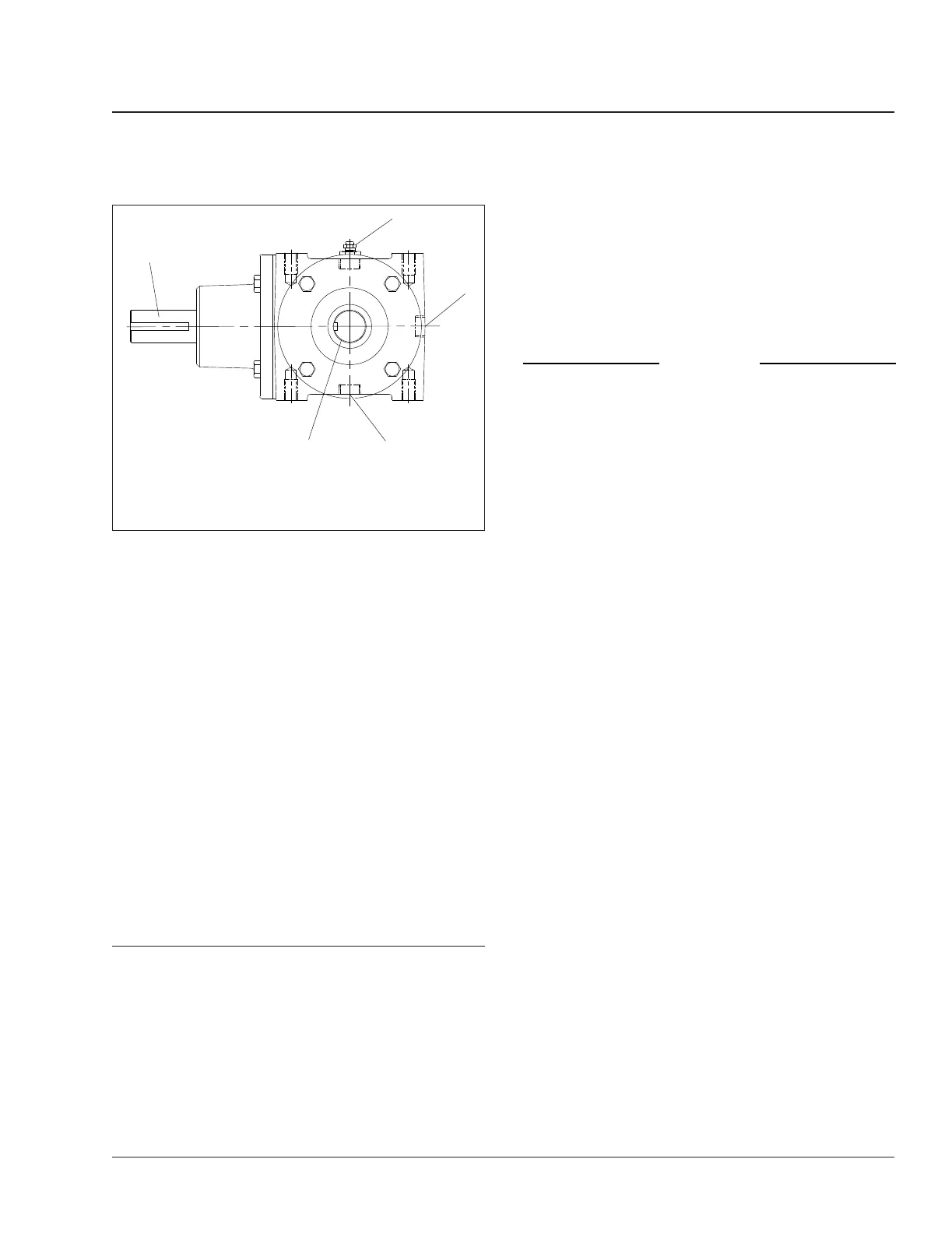

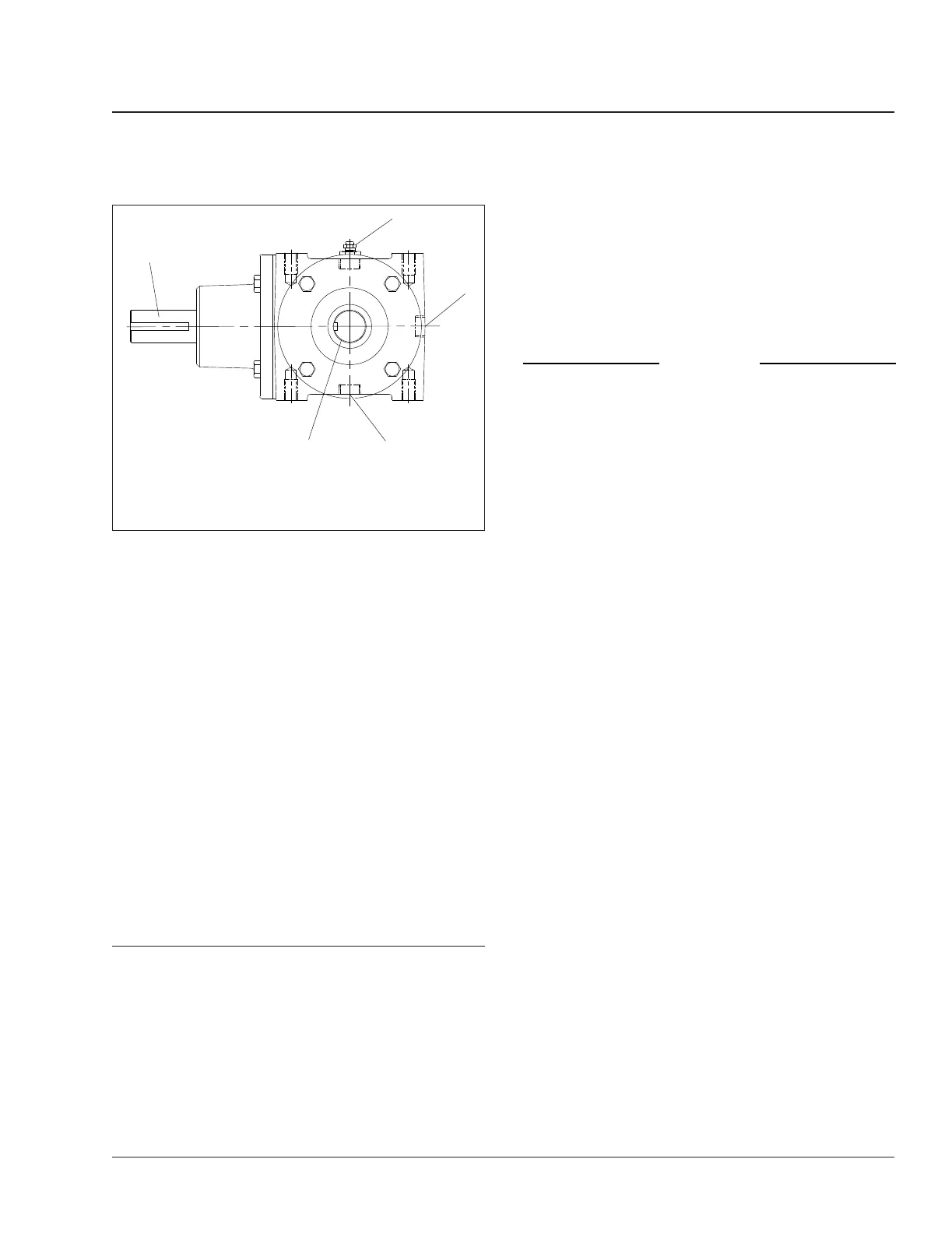

20–05 Mechanical Fan Drive

Gearbox Lubrication

U-Joint Lubrication

1. Wipe all old grease and dirt from each U-joint

grease fitting.

2. Use a hand-type grease gun, or a high-pressure

gun with a low-pressure adaptor, to lubricate the

U-joints. See

Fig. 3.

NOTE: If a low-pressure adaptor is not used

with the high-pressure gun, the U-joints may not

receive enough lubricant.

3. Using lithium 12-hydroxy stearate grease (NLGI

grade 2, with EP additives and meeting ASTM

D4950 LB specifications), lubricate until new

grease can be seen at both U-joint seals.

NOTICE

Fresh lubricant must be seen escaping from both

of the bearing cup seals of each U-joint. If not, the

U-joint may fail prematurely.

4. If the bearing will not take grease, replace the

U-joint assembly.

5. Check the old grease. If it appears rusty, gritty, or

burned, replace the U-joint assembly.

6. Wipe any excess grease from the seals and

grease fittings.

Slip-Joint Spline Lubrication

1. Check the slip-joints for spline wear by trying to

bend the sleeve-yoke and splined shaft back and

forth. If looseness is greater than 0.007 inch

(0.18 mm), replace both the sleeve-yoke and the

splined shaft.

2. Wipe all old grease and dirt from the slip-joint

grease fitting.

3. Use a hand-type grease gun or a high-pressure

gun with a low-pressure adaptor, to lubricate the

slip-joint. See

Fig. 3. Using lithium 12-hydroxy

stearate grease (NLGI grade 2, with EP additives

and meeting ASTM D4950 LB specifications),

lubricate until fresh grease appears at the

pressure-relief hole in the yoke plug. Then cover

the relief hole with your finger, while continuing

to lubricate until fresh grease appears at the slip-

joint seal. This ensures complete lubrication of

the splines.

4. Wipe any excess grease from the pressure-relief

hole, slip-joint seal, and grease fitting.

08/31/2011

1

2

3

4

5

f200744

1. Pinion Shaft

2. Breather/Fill Plug

3. Oil Level Plug

4. Drain Plug

5. Cross-Shaft

Fig. 2, Mechanical Fan Drive Gearbox

Engine Cooling/Radiator 20

Recreational Vehicle Chassis Maintenance Manual, October 2016 20/3

Loading...

Loading...