En-9

6.3.3. Wiring procedure

CAUTION

When connecting the power supply cable, make sure that the phase of the power

supply matches with the phase of the terminal board. If the phases do not match, the

compressor will rotate in reverse and will not be able to compress.

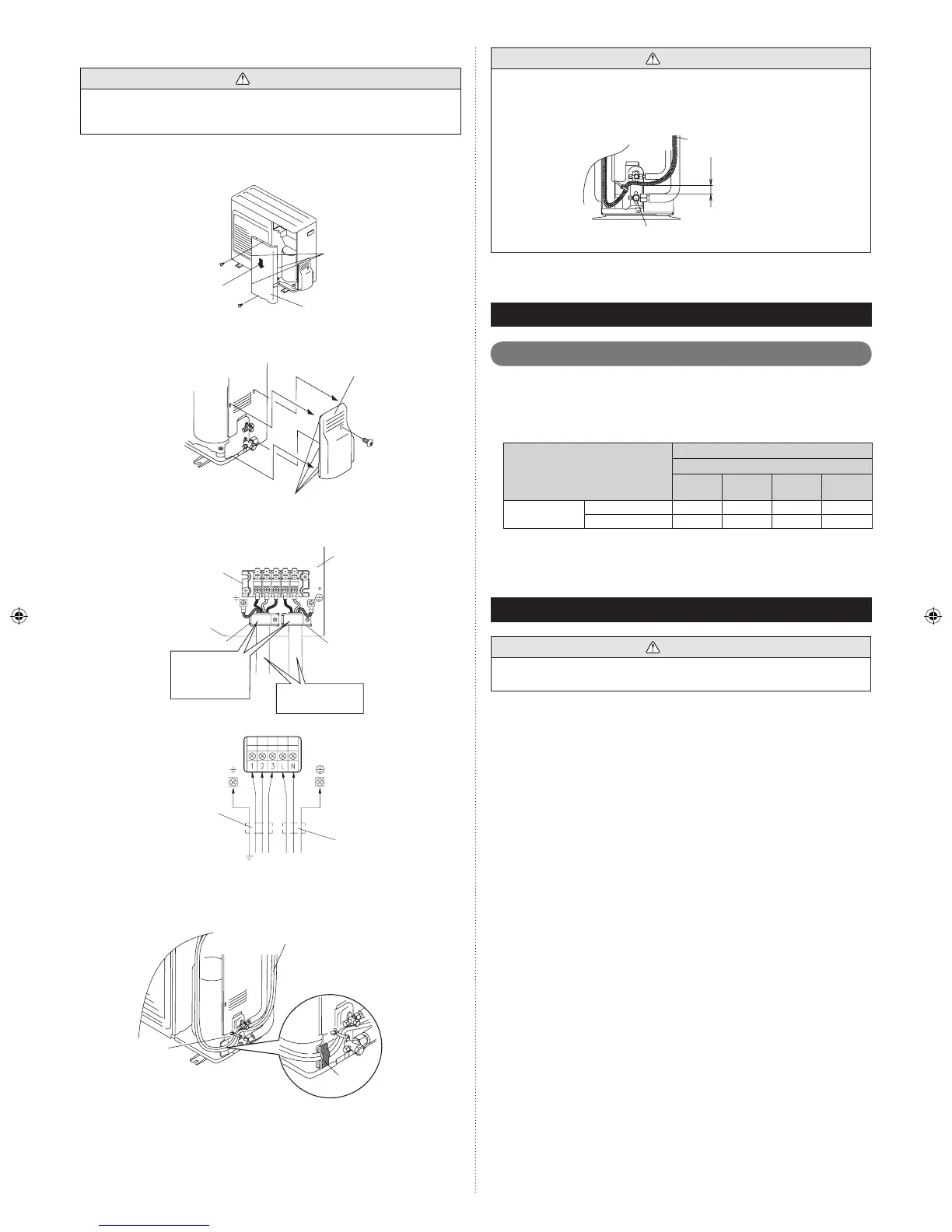

(1) Service cover removal

• Remove the two mounting screws.

• Remove the service cover by pushing downwards.

Direction of the

service cover

removal

Hook (3 places)

Service cover

(2) Valve cover removal.

• Remove the one mounting screw.

• Remove the valve cover by sliding upward.

Hook (4 places)

Valve cover

(3) Connect the power supply cable and the connection cable to terminal.

(4) Fasten the power supply cable and connection cable with cable clamp.

Terminal blocks

Firmly secure

cable clamp so

wire terminations

will not receive

external stress.

Use the specied

wire type and

connect it securely.

Cable clamp

Cable clamp

Control box

Connection cable

Power supply cable

Indoor

unit

EARTH

(5) Power supply cable and connection cable should be xed with cable clip as shown in

the gure.

Fill in a gap at the entrance of the cables with insulation (seal).

Cable clip

Power supply cable and connection cable

Insulation

(Seal)

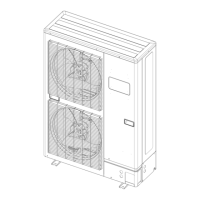

CAUTION

Fix cables so that cables do not make contact with the pipes (especially on high

pressure side).

Do not make power supply cable and connection cable come in contact with valve

(Gas).

Power supply cable

and connection cable

Valve

(Gas)

Gap

(6) Put the service cover and valve cover back after completion of the work.

7. PIPE INSTALLATION-2

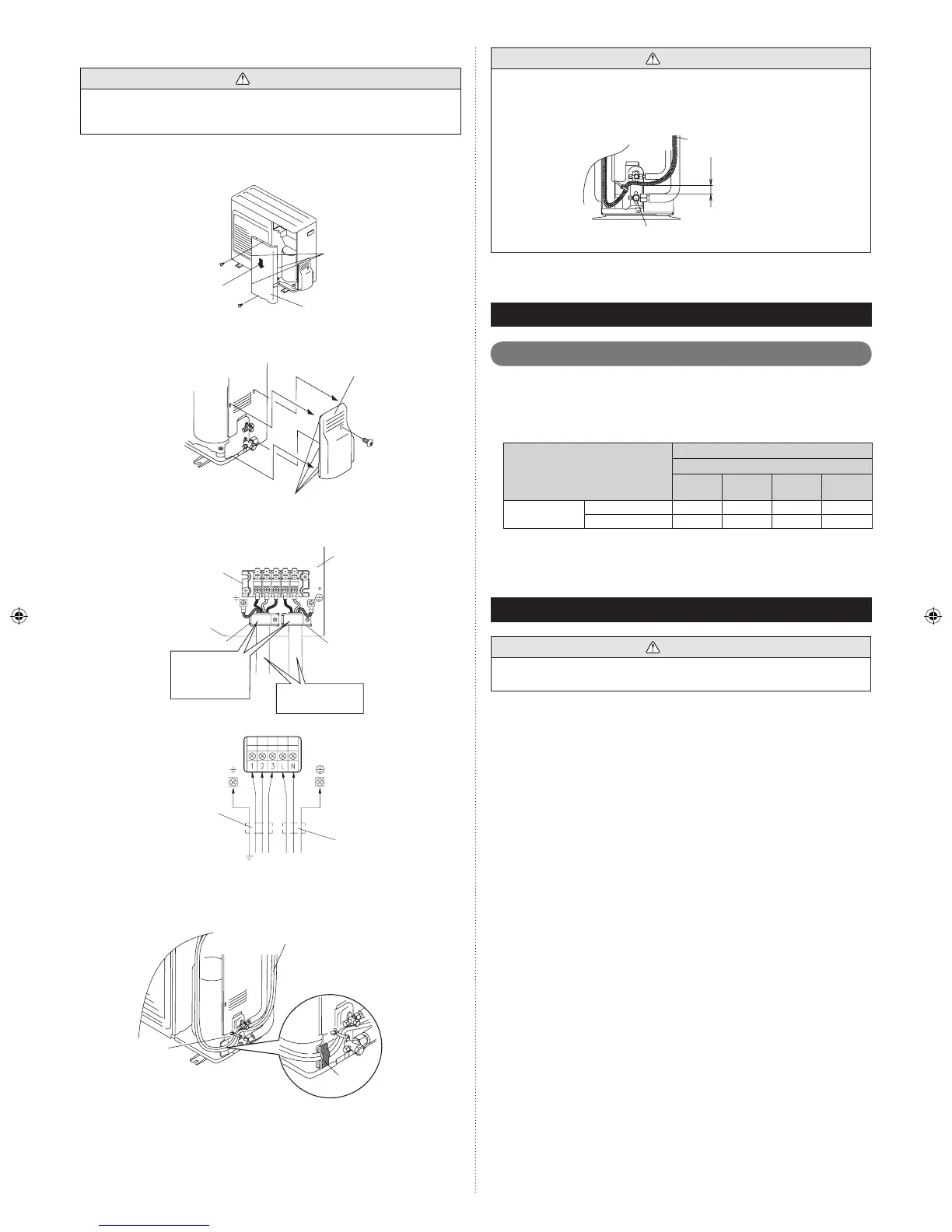

Installing insulation

Determine the thickness of the insulation material by referring to Table A.•

Table A, Selection of insulation

(for using an insulation material with equal heat transmission rate or below

0.040 W/(m·k))

Relative humidity

[mm (in.)]

Insulation material

Minimum thickness [mm]

70%

or more

75%

or more

80%

or more

85%

or more

Pipe diameter

9.52 (3/8) 9 11 14 18

15.88 (5/8) 10 12 16 20

If the ambient temperature and relative humidity exceed 32 °C, increase the level of •

heat insulation for the refrigerant pipes.

8. TEST RUN

CAUTION

Always turn on the power 12 hours prior to the start of the operation in order to ensure

compressor protection.

Make a TEST RUN in accordance with the installation instruction sheet for the indoor unit.

Loading...

Loading...