En-12

(♦... Factory setting)

Function Number

Setting

Value

Setting Description

95

00 Standard insulation ♦

01 High insulation

■

Room temperature control for indoor unit sensor

Depending on the installed environment, correction of the room temperature sensor may

be required.

Select the appropriate control setting according to the installed environment.

The temperature of the room temperature sensor is corrected as follows:

Corrected temp. = Temp. of room temp. sensor - correction temp. value

Example of correction :

When the temperature of room temp. sensor is 78 °F and the setting value is

“03” (-2 °F), the corrected temp. will be 80 °F (78 °F [-2 °F]).

The temperature correction values show the difference from the “Standard setting” (00)

(manufacturer’s recommended value).

(♦... Factory setting)

Function number

Setting

value

Setting description

30

(For cooling)

31

(For heating)

00 Standard setting ♦

01 No correction 0 °F (0.0 °C)

02 -1 °F ( -0.5 °C)

More

Cooling

Less

Heating

03 -2 °F (-1.0 °C)

04 -3 °F (-1.5 °C)

05 -4 °F (-2.0 °C)

06 -5 °F (-2.5 °C)

07 -6 °F (-3.0 °C)

08 -7 °F (-3.5 °C)

09 -8 °F (-4.0 °C)

10 +1 °F (+0.5 °C)

Less

Cooling

More

Heating

11 +2 °F (+1.0 °C)

12 +3 °F (+1.5 °C)

13 +4 °F (+2.0 °C)

14 +5 °F (+2.5 °C)

15 +6 °F (+3.0 °C)

16 +7 °F (+3.5 °C)

17 +8 °F (+4.0 °C)

■

Room temperature control for wired remote controller sensor

Depending on the installed environment, correction of the wire remote temperature sensor

may be required.

Select the appropriate control setting according to the installed environment.

To change this setting, set Function 42 to “Both” (01).

Ensure that the Thermo Sensor icon is displayed on the remote controller screen.

(♦... Factory setting)

Function number

Setting

value

Setting description

35

(For cooling)

36

(For heating)

00 No correction ♦

01 No correction 0 °F (0.0 °C)

02 -1 °F ( -0.5 °C)

More

Cooling

Less

Heating

03 -2 °F (-1.0 °C)

04 -3 °F (-1.5 °C)

05 -4 °F (-2.0 °C)

06 -5 °F (-2.5 °C)

07 -6 °F (-3.0 °C)

08 -7 °F (-3.5 °C)

09 -8 °F (-4.0 °C)

10 +1 °F (+0.5 °C)

Less

Cooling

More

Heating

11 +2 °F (+1.0 °C)

12 +3 °F (+1.5 °C)

13 +4 °F (+2.0 °C)

14 +5 °F (+2.5 °C)

15 +6 °F (+3.0 °C)

16 +7 °F (+3.5 °C)

17 +8 °F (+4.0 °C)

■

Setting record

•

Record any changes to the settings in the following table.

Function

number

Setting Description

Setting Value

95 Heat Insulation condition (building insulation)

30

Room temperature control for indoor unit

sensor

Cooling

31 Heating

35

Room temperature control for wired remote

controller sensor

Cooling

36 Heating

After completing the Function setting, be sure to disconnect the power and reconnect it

again.

6. TEST RUN

■

Check items

(1) Is operation of each button on the remote control unit normal?

(2) Does each lamp light normally?

(3) Do air ow direction louvers operate normally?

(4) Is the drain normal?

(5) Do not have an abnormal noise and vibration during operation?

(6) Is there an error left in the error memory?

• After installation, check that the display is “00 (normal)”.

(For checking whether the display shows “00”, refer to “

■Service check in the Operation

manual”.)

- If the display is other than “00 (normal)” even though it works normally, erase the error

memory

- For “

■How to check the error memory” and “■How to erase the error memory”, refer

to the lower section of the “9. ERROR CODES” list.

• Do not operate the air conditioner in test run for a long time.

(If you leave it as it is after the test run starts, it will end automatically in about 60

minutes.)

■

Operation method

Before starting the test run, wait for 1 minute after connecting the power supply.

By the wireless remote controller

• To start the test run, press [START/STOP(

)], press and hold [ ] on the remote

control for 5 seconds or more by using the tip of a ballpoint pen or other small object.

By the indoor unit

• To start the test run, keep on pressing the indoor unit button for more than 10 seconds.

• To end test operation, press the remote controller [START/STOP(

)].

(When the air conditioner is running by pressing [

], the “OPERATION” Lamp and

“TIMER” Lamp will simultaneously ash slowly.)

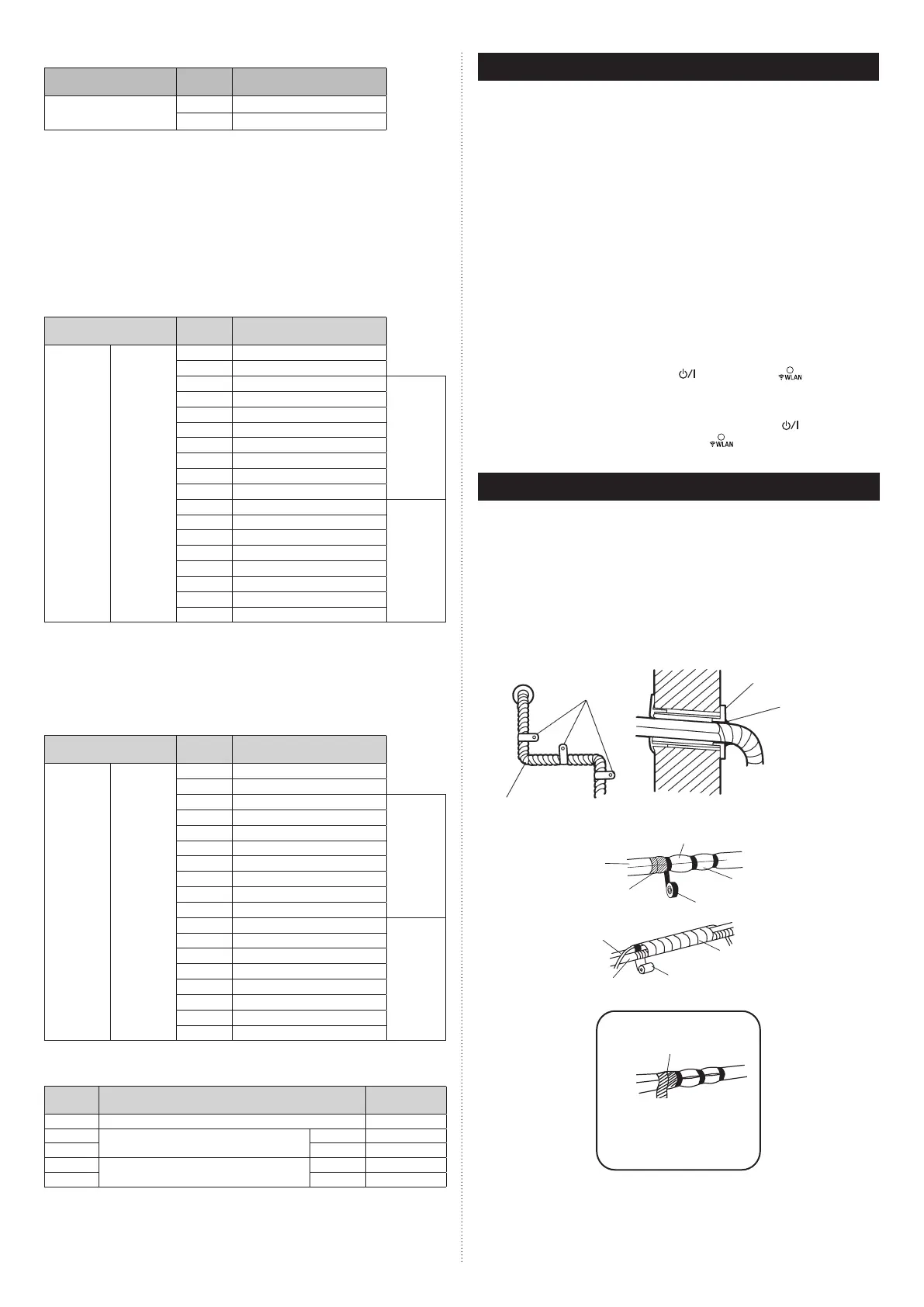

7. FINISHING

(1) Insulate between pipes.

• Insulate suction and discharge pipes separately.

• For rear, right, and bottom piping, overlap the connection pipe heat insulation and

indoor unit pipe heat insulation and bind them with vinyl tape so that there is no gap.

(2) Temporarily fasten the connection cable along the connection pipe with vinyl tape.

(Wrap to about 1/3 the width of the tape from the bottom of the pipe so that water

does not enter.)

(3) Fasten the connection pipe to the outside wall with a saddle, etc.

(4) Fill the gap between the outside wall pipe hole and the pipe with sealer so that rain

water and wind cannot blow in.

(5) Fasten the drain hose to the outside wall, etc.

(6) Check the drainage.

*Locally purchased

Pipe

Saddle*

Outside wall cap*

Sealer putty*

(Outdoors)

Wall

Overlap the insulation

Vinyl tape*

Wrap with cloth tape.

Cloth tape (accessory)

Drain hose

Pipe

Connection pipe

(heat insulation)

Indoor unit pipe

(heat insulation)

Bind the pipes together

so that there is no gap.

Drain hose insulation is used

when the diameter of gas pipe is

Ø12.70 or more.

Butt connection pipe (heat

insulation) against the indoor unit

pipe (heat insulation) and wrap

with drain hose insulation so that

there is no gap.

9387082593-01_IM.indb 129387082593-01_IM.indb 12 28-Oct-21 13:52:5728-Oct-21 13:52:57

Loading...

Loading...