Maintenance

Installation Instructions (Cont.)

The F2 jack is designed with precision fit components and corrosion resistant materials to minimize the frequency of maintenance. Occasional cleaning

with mild soap and water along with light oil lubrication of pivot points will prolong peak performance and appearance.

Lock

Nut

Roller

Spacer

Washer

Bolt

Handle

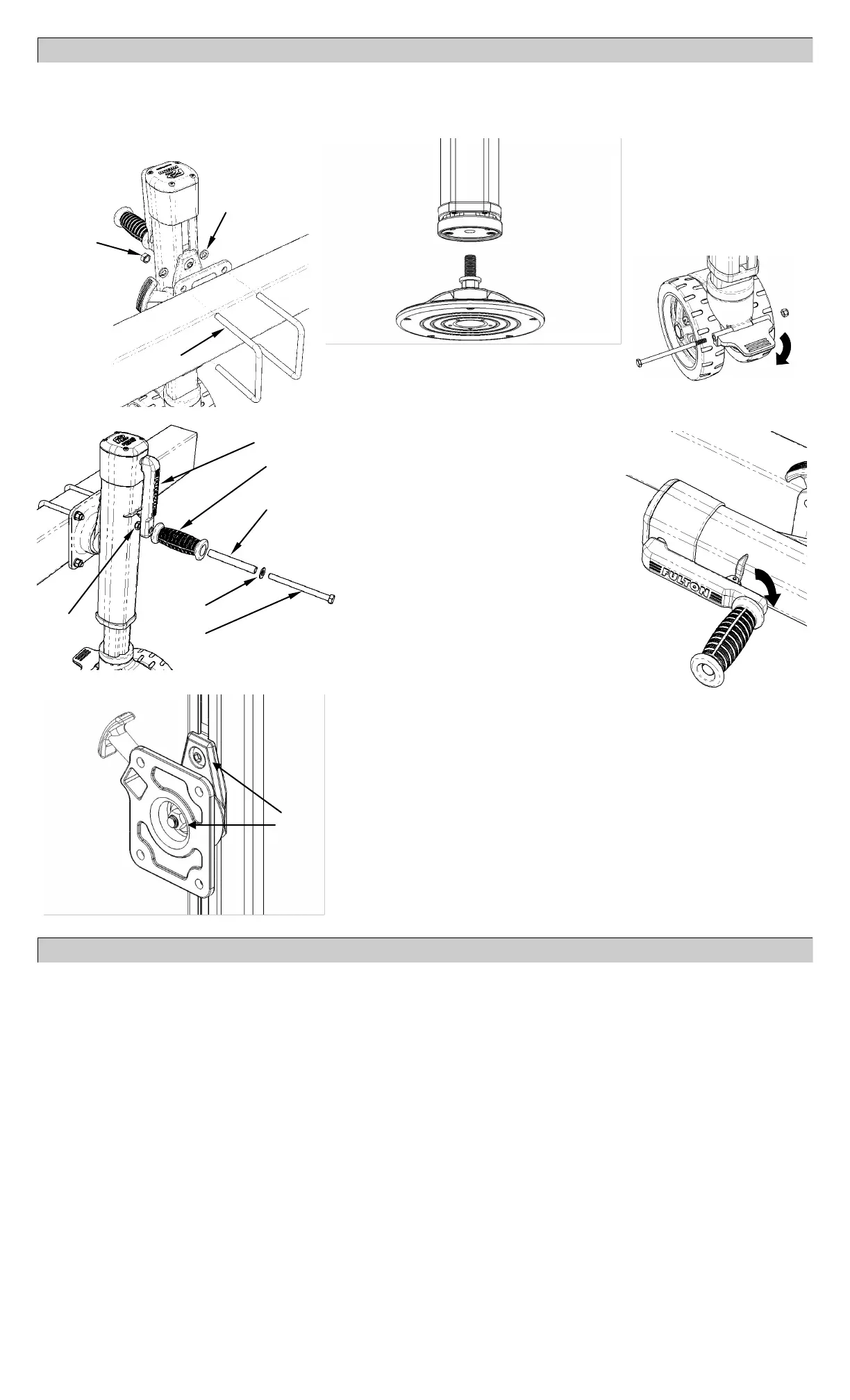

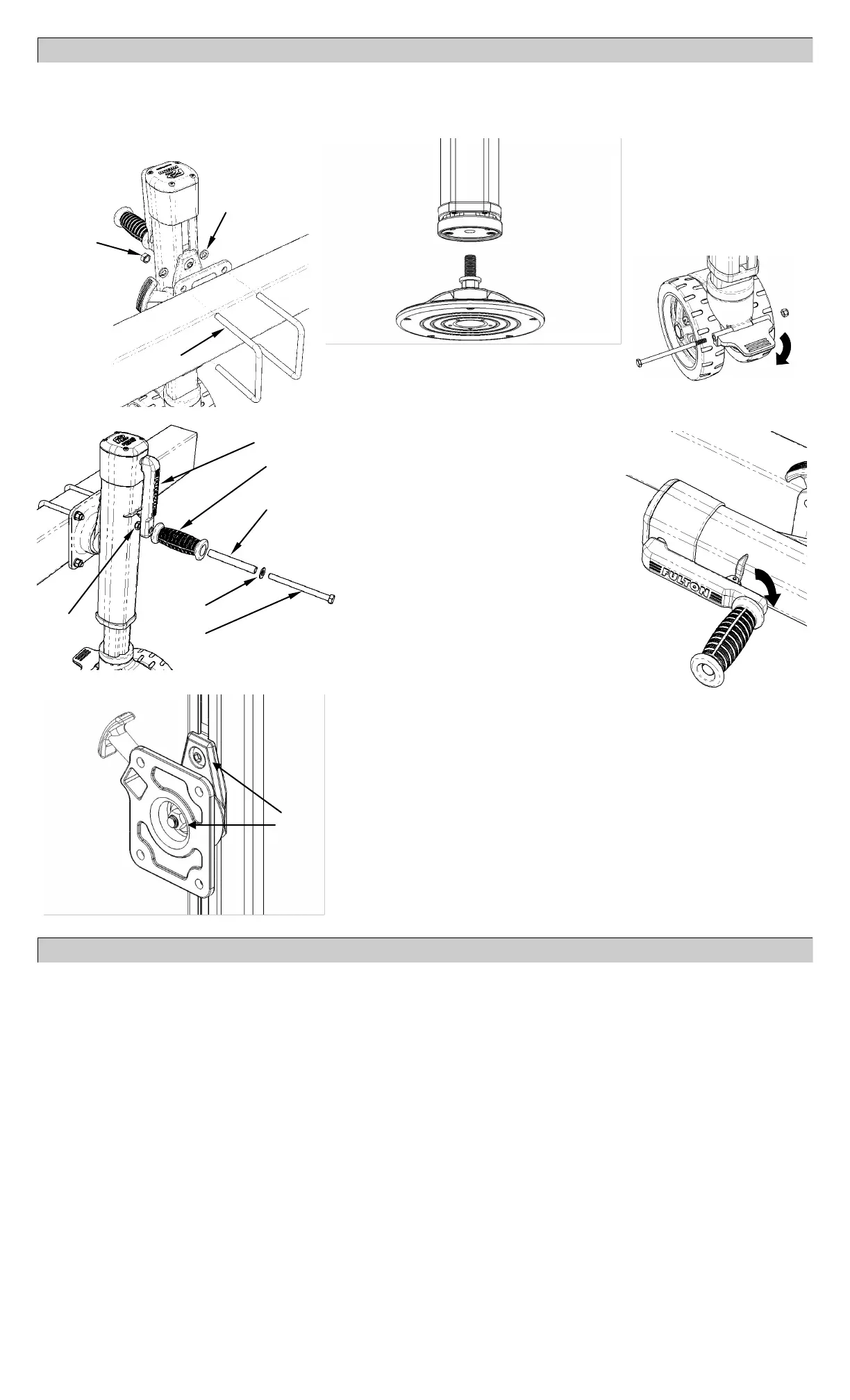

Bolt-on:

Available in 3”x 3”, 3”x 4”, or 3”x5” trailer tubes

only. Position swivel bracket and U-bolts to allow

proper mounting to trailer. Tighten nuts and torque to

20-25 ft-lbs.

Nut

Lock Washer

U-Bolt

(4” shown)

Bolt-on

(U-bolts)

Optional

Wheel Wedge

To lock

Optional

Handle Hold-Up

To disengage

Footplate

Adjusting Swivel Mount Height (If Necessary):

With jack removed from trailer, loosen the two swivel fasteners until

the slide block moves freely along outer tube. To access the upper

bolt be sure the swivel bracket is rotated in the horizontal (3”

mounting) position as shown. Adjust swivel mount to desired

location and re-torque to 60-70 ft.-lbs. After adjustment, check for

proper swivel and pin engagement.

Swivel Fasteners

Handle Assembly

Optional Wheel Wedge:

Assemble the optional Wheel Wedge

as shown in the diagram below and

torque to 6-9 in-lbs. To activate, press

downward until wedge locks into

place. To release, lift up until pressure

is released from wheels. Wheel Wedge

is not intended to be a wheel brake or

stop.

Footplate: Thread footplate into the bottom of the

jack tube. Torque to 60-70 ft.-lbs.

Optional Handle Hold-Up:

To assemble, place Handle Hold-up with its

stop block pointing toward top of jack. Center

hold-up on handle and drive pin flush through

hold-up & both tabs. Proper assembly allows

Handle Hold-up to rotate down in the event of

crank handle bypass.

Jack and handle shown

in stowed position

Installing Handle Assembly:

Assemble handle assembly as shown and

torque locknut to 20-25 in-lbs.

Loading...

Loading...