Mounting Bolt Torque 28-30 ft./lbs. 28-30 ft./lbs.

Installation Instructions

Mounting Hardware Requirements

Refer to Table 2 below for bolt quantity, sizes, and required torque. Mounting system will dictate bolt

length.

ALWAYS torque mounting bolts to the values specified for your winch in Table 2.

ALWAYS use grade 5 (class 8.8 metric) hardware.

NEVER weld mounting bolts.

ALWAYS choose the proper bolt length for your application.

ALWAYS confirm required bolt length to ensure proper thread engagement. A minimum of two whole

threads should protrude from the nut.

1.2 Select Mount Location

ALWAYS choose a mounting location that is sufficiently strong to withstand the maximum

pulling capacity of your winch.

1.2.1 Winch Mounting

Considerations

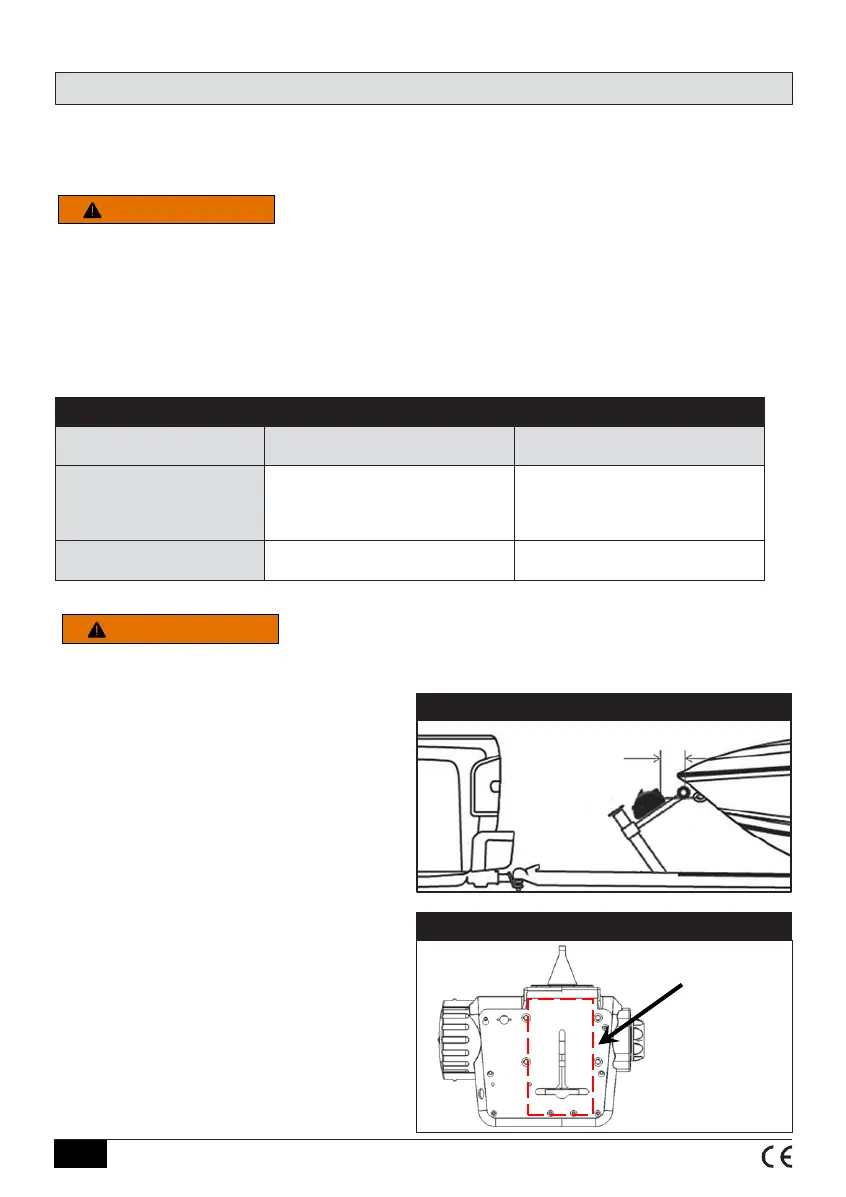

Your mounting surface must be equal to or

greater than the mounting surface of the

winch frame. See Figure 3. Three sets of

3/8”, Grade 5, hardware are required to

mount this winch.

The winch should be positioned so that the

strap exits the winch horizontal to the bow

eye when the boat is fully loaded onto the

trailer.

The fairlead should be a minimum of 6” away

from the bow eye when the boat is fully loaded

onto the trailer. See Figure 2.

Figure 3 - MountingSurface

Minimum

Mounting

Area

4.5” x 6”

Figure 2 - MountLocation

Minimum distance

from the bow eye to

the winch, when the

boat is fully loaded

on to the trailer

6”

WARNING

©2021 Horizon Global Americas Inc. • F4088-00 REV D (7871) 08/2021

E6

Loading...

Loading...