11

ADJUSTMENTS

Caution! Always ensure that the Circular Saw is

disconnected from the mains supply before carrying

out any maintenance or adjustments.

DEPTH OF CUT AT 90°

The Circular Saw has an adjustable depth of cut. To

adjust the depth of cut slacken the lever located on

the side of the machine (Fig. 13).

Measure the depth required from the base plate to the

highest point of the blade or use the depth gauge on

the fixed guard Fig 14.

ANGLE OF CUT 0-45°

To adjust the angle of cut between 0-45° slacken the

adjustable angle of cut locking knob Fig 15.

The base plate assembly will now pivot between 0-

45°. Set the desired cutting angle by using degree

scale at the front of the machine and tighten locking

knobs.

At the front of the base plate there are two notches

marked 90° and 45°. These notches are a guide to

indicate the position of the blade in relation to the cut

being made in the material.

STARTING AND STOPPING

To start the machine, press in the safety switch Fig 16

(A) then depress and hold in the trigger (B). There is

no need to hold the safety switch in as it remains in

place as long as the trigger is depressed. To stop the

saw, release the trigger, which allows the safety

switch to return to the locked position. Do not attempt

to jam the safety switch.

MAINTENANCE

Warning! When servicing only use identical

replacement parts. Use of any other parts may create

a hazard or cause product damage.

Warning! Always wear safety goggles or safety

glasses with side shields during power tool operation

or when blowing dust. If operation is dusty, also wear

a dust mask.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts.

Most plastics are susceptible to damage from various

types of commercial solvents and may be damaged

by their use. Use clean cloths to remove dirt, dust, oil,

grease, etc.

Warning! Do not at any time let brake fluids, gasoline,

petroleum based products, penetrating oils, etc.,

come in contact with plastic parts. Chemicals can

damage, weaken or destroy plastic which may result

in serious personal injury.

Electric tools used on fiberglass material, wallboard,

spackling compounds, or plaster are subject to

accelerated wear and possible premature failure

because the fiberglass chips and grindings are highly

abrasive to bearings, brushes, commutators, etc.

Consequently, we do not recommended using this

tool for extended work on these types of materials.

However, if you do work with any of these materials, it

is extremely important to clean the tool using

compressed air.

LUBRICATION

All of the bearings in this tool are lubricated with a

sufficient amount of high grade lubricant for the life of

the unit under normal operating conditions. Therefore,

no further lubrication is required.

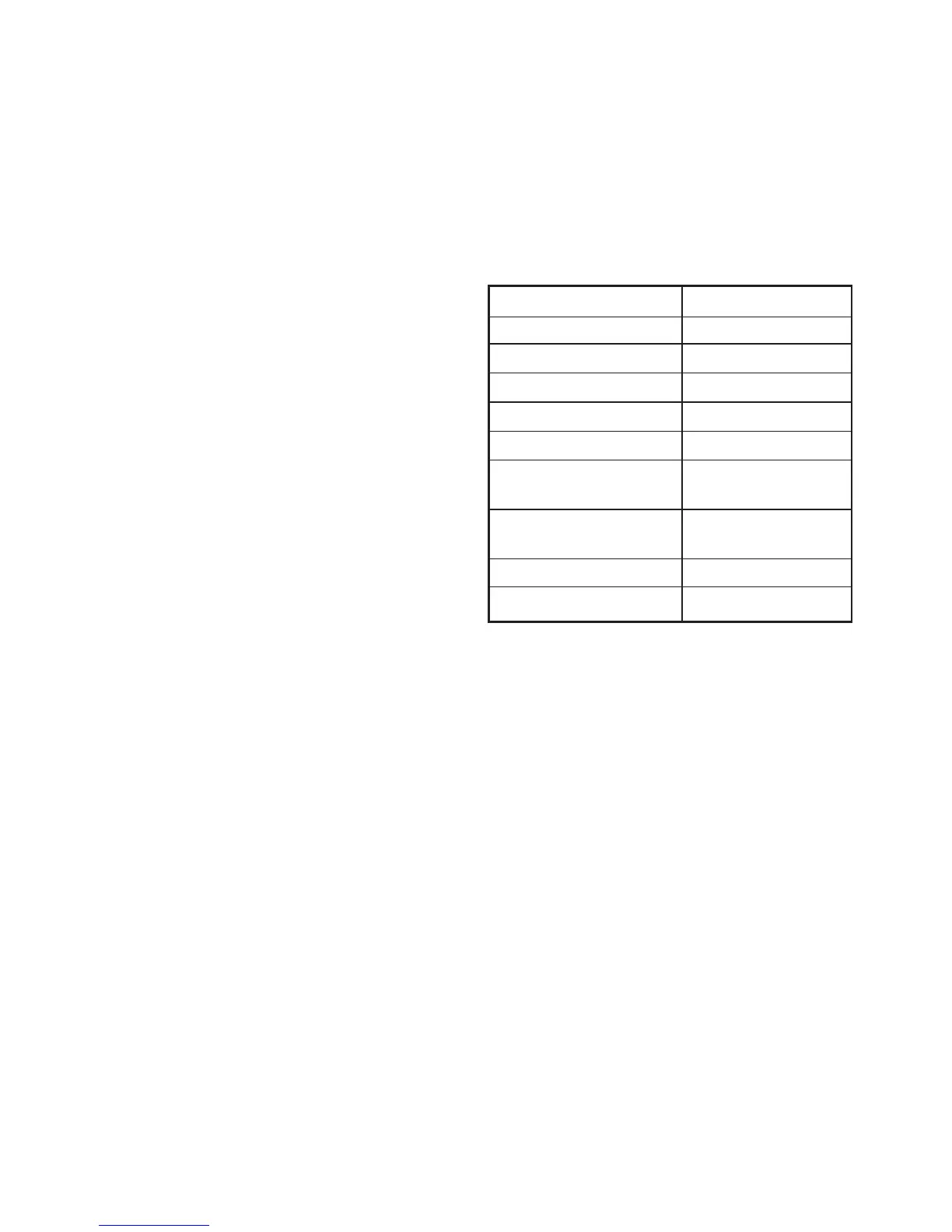

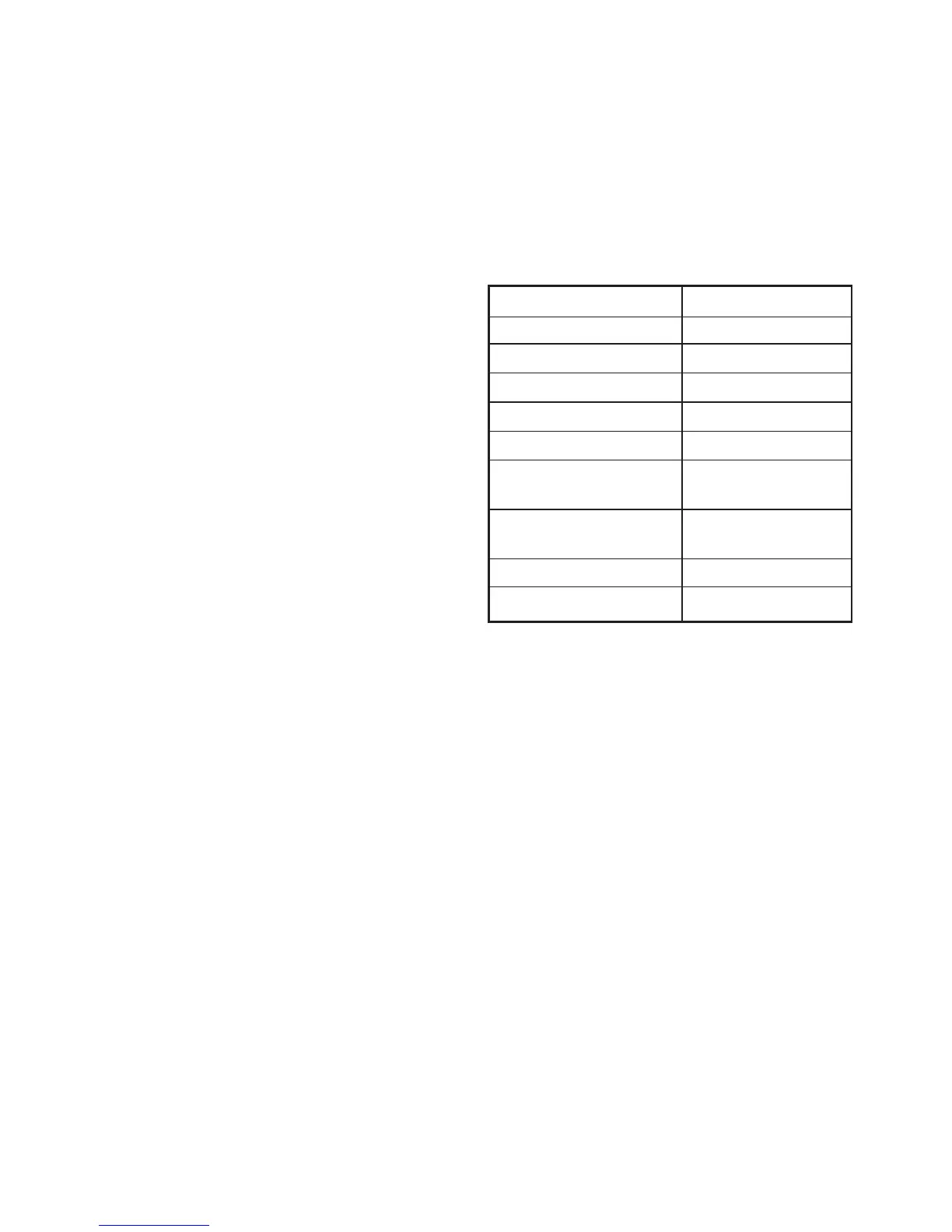

TECHNICAL SPECIFICATION

Voltage 230V - 50Hz

Rated input 1200W

No load speed 5000min

-1

Blade size 185 x 20mmØ

Max cutting depth 90º 65mm

Max cutting depth 45º 44mm

Sound Pressure Level L

pA

94.05 dB(A)

K=3dB(A)

Sound Power Level L

WA

105.05 dB(A)

K=3dB(A)

Vibration Level 2.144 m/s

2

, K=1.5m/s

2

Weight 3.9 kg

Loading...

Loading...